A chemical modification method and modification device for aramid fiber

A kind of aramid fiber, chemical modification technology, applied in fiber processing, textiles and papermaking, etc., can solve the problems of limited effect of aramid fiber modification, difficulty, low production efficiency, easy to control the reaction process, avoid waste, The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

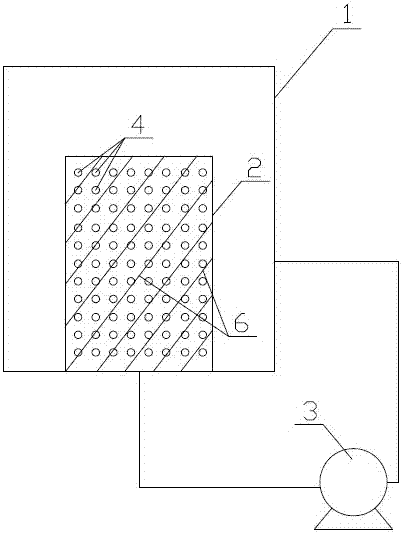

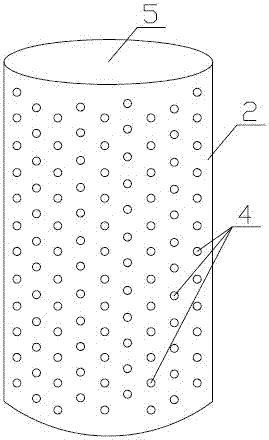

Image

Examples

Embodiment 1

[0047] A chemical modification method for aramid fibers, comprising the following process steps:

[0048] A. Preparation of surface modification treatment agent

[0049] Under the protection of an inert gas, the acid chloride active reaction reagent or the acid anhydride active reaction reagent is dissolved in an anhydrous strong polar organic solvent to prepare an active solvent system, that is, a surface modification treatment agent; the acid chloride active reaction reagent It is any one of acetyl chloride, propionyl chloride, chloroacetyl chloride, dichloroacetyl chloride, trichloroacetyl chloride, thionyl chloride, chloropropionyl chloride or several mixtures in any proportion; the acid anhydride reactive reagent is acetyl chloride Acid anhydride, propionic anhydride, fluoroacetic anhydride, chloroacetic anhydride, bromoacetic anhydride, iodoacetic anhydride, or a mixture of any of them in any proportion; the strong polar organic solvent is N-methylpyrrolidone , any one ...

Embodiment 2

[0056] On the basis of embodiment 1:

[0057] Preferably, in step A, the volume percent concentration of the acid chloride reactive reagent or acid anhydride reactive reagent dissolved in anhydrous strong polar organic solvent is 10%.

[0058] Preferably, in step B, the reaction temperature is 30° C., and the reaction time is 10 minutes.

[0059] Preferably, in step C, the washing is performed with deionized water at 50°C, and the drying temperature is 120°C.

Embodiment 3

[0061] On the basis of embodiment 1:

[0062] Preferably, in step A, the volume percent concentration of the acid chloride reactive reagent or acid anhydride reactive reagent dissolved in an anhydrous strong polar organic solvent is 50%.

[0063] Preferably, in step B, the reaction temperature is 50° C., and the reaction time is 20 minutes.

[0064] Preferably, in step C, the washing is performed with 80°C deionized water, and the drying temperature is 140°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com