Radial radiating beam electron gun suitable for radial logarithmic spiral microstrip slow-wave line

A technology of logarithmic spiral and slow wave line, which is applied in the field of vacuum electronic devices to achieve the effects of not easy to fall off or drop, low manufacturing cost and high working voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

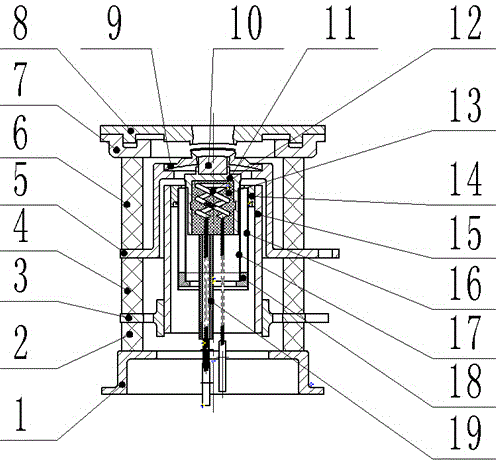

[0041] A radially diverging electron injection gun suitable for radial logarithmic spiral microstrip slow wave lines, the electron gun and the background technology application number is 201210409251.6, the name is "a radial logarithmic spiral microstrip slow wave line" invention Complementary use with the patent pending slow wave line. The electron gun includes a gun casing, and a cathode assembly, a control electrode 9 and an anode 8 are arranged in the gun casing. The anode 8 has a disk-shaped structure, and a radial hole is opened in the middle of the disk of the anode 8 , and the angle of the radial hole of the anode 8 is determined by the radial opening angle of the cathode head 10 . The control pole 9 is also a disc-shaped structure, and a radial hole is opened in the middle of the disc of the control pole 9. When the cathode assembly and the control pole 9 are assembled, the cathode head 10 of the cathode assembly is placed in the radial hole of the control pole 9 Ins...

Embodiment 2

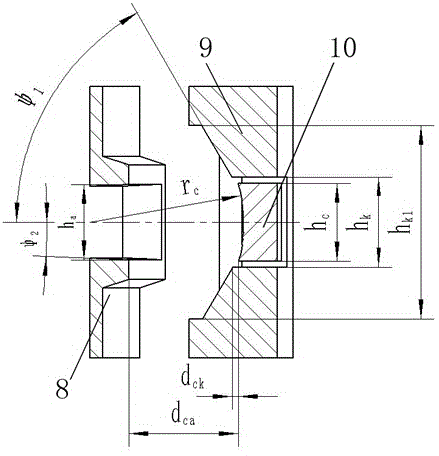

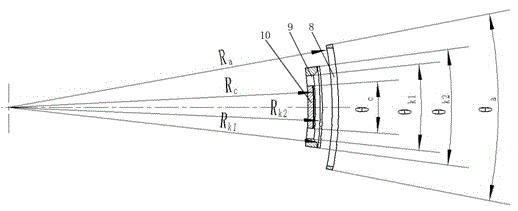

[0045] On the basis of Embodiment 1, the axial width h of the cathode head 10 c =0.6 mm, the axial width h of the radial hole of the control pole 9 k =1.6mm, the axial width h of the opening step of the control pole 9 k1 =0.7mm, the axial width h of the axial opening of the anode 8 a =0.46mm, the distance d between the end face of the cathode head 10 on the side close to the anode 8 and the end of the radial hole of the control electrode 9 on the side close to the anode 8 ck =0.05mm, the distance d between the cathode tip 10 and the anode 8 ca =0.7mm, the cathode emission surface of the cathode head 10 is a cylindrical emission surface, and the radius of curvature r of the cathode emission surface of the cathode head 10 c →∞, the inclination angle ψ of the inner angle of the radial hole of the control pole 9 to the slopes on the left and right sides 91 1 =60°, the inclination angle ψ of the slope protrusions 91 on the upper and lower sides in the radial hole of the control...

Embodiment 3

[0049] On the basis of Embodiment 1, the axial width h of the cathode head 10 c =0.6mm, the axial width h of the radial hole of the control pole 9 k =0.6mm, the axial width h of the opening step of the control pole 9 k1 =0.7mm, the axial width h of the axial opening of the anode 8 a =0.58mm, the distance d between the end face of the cathode head 10 on the side close to the anode 8 and the end of the radial hole of the control electrode 9 on the side close to the anode 8 ck =0.05mm, the distance d between the cathode tip 10 and the anode 8 ca =0.45mm, the cathode emission surface of the cathode head 10 is a hyperboloid emission surface, and the radius of curvature r of the cathode emission surface of the cathode head 10 c = 1.19mm, the inclination angle ψ 1 =60°, the inclination angle ψ of the slope protrusions 91 on the upper and lower sides in the radial hole of the control pole 9 3 =45°, the inclination angle ψ of the radial hole of the anode 8 2 =3°; in the angular s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com