Method for preparing novel micro nano composite structure patterned sapphire substrate

A technique for patterning sapphire and sapphire substrates, applied in nanotechnology, semiconductor/solid-state device manufacturing, electrical components, etc. Graphics and other problems, to achieve excellent etching resistance, improve internal quantum efficiency, reduce the effect of dislocation density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

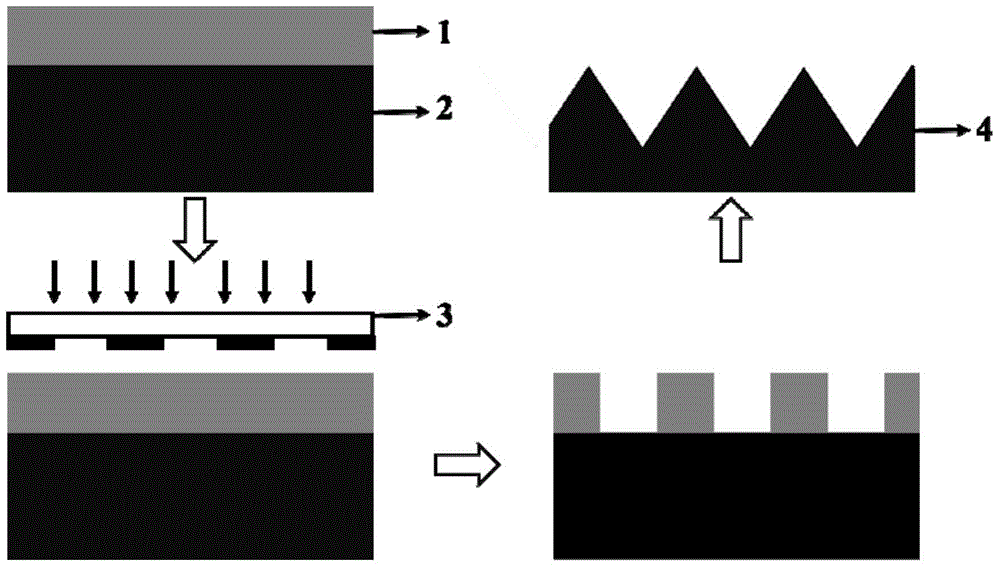

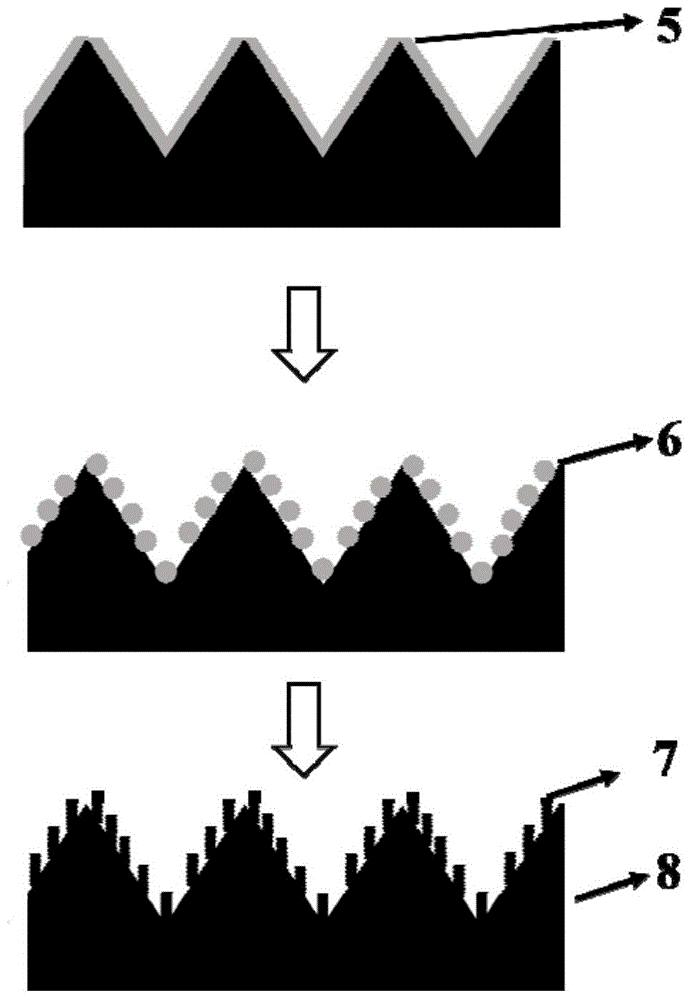

[0026] The present invention first prepares a micron-patterned sapphire substrate by photolithography and sapphire etching, and its period is adjustable; secondly, 10nm metal Ni is vapor-deposited on the surface of the substrate by electron beam evaporation coating equipment; The substrate is put into the annealing furnace, and according to the difference of annealing temperature and time, metal Ni nanoparticles (average diameter is 100-400nm) with adjustable diameter are obtained; the substrate with metal Ni particles is subjected to ICP etching, according to the etching Depending on the time, nano-sapphire column arrays with different depths were etched; the residual Ni mask was removed from the above-etched substrate in dilute nitric acid to obtain a new micro-nano composite structure patterned sapphire substrate.

[0027] In this embodiment, the met...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com