Na fast-ion conductor Na3PSe4 and preparation method thereof

An ion conductor and ion conduction technology, applied in the field of new energy materials, to achieve the effect of increasing ion conductivity, high ion conductivity, and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Elemental Na (>99%), P (red phosphorus, 99.999%), Se (99.999%) were weighed in the glove box according to the molar ratio Na:P:Se=3:1:4, and put into an alumina crucible After that, put the crucible into a quartz tube with one end closed, evacuate to 0.1Pa, and seal the quartz tube. Put the sealed quartz tube after firing into a muffle furnace, heat it up to 850°C at a heating rate of 0.2°C / min, keep it warm for 24 hours, and finally cool it down to room temperature in the furnace. The cooled mass was removed from the quartz tube and ground into a powder manually with a mortar in a glove box.

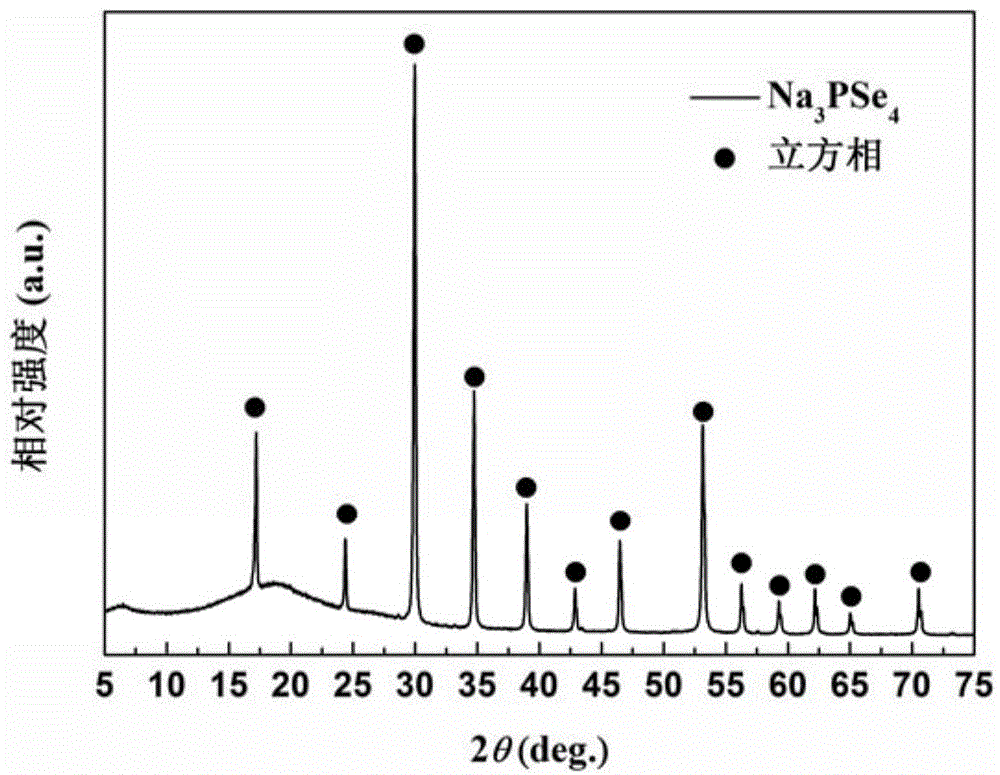

[0021] After the sample powder is sealed with a polyimide film, X-ray diffraction (XRD) test is carried out. The test adopts SmartLab (40kV, 40mA, Cu Ka, ), the test range is 5~75°, and the rate is 3° / min. Such as figure 1 As shown, the curve is Na 3 PSe 4 The X-ray diffraction pattern of the sodium solid electrolyte, showing that the prepared sample is a pure cubic phase o...

Embodiment 2

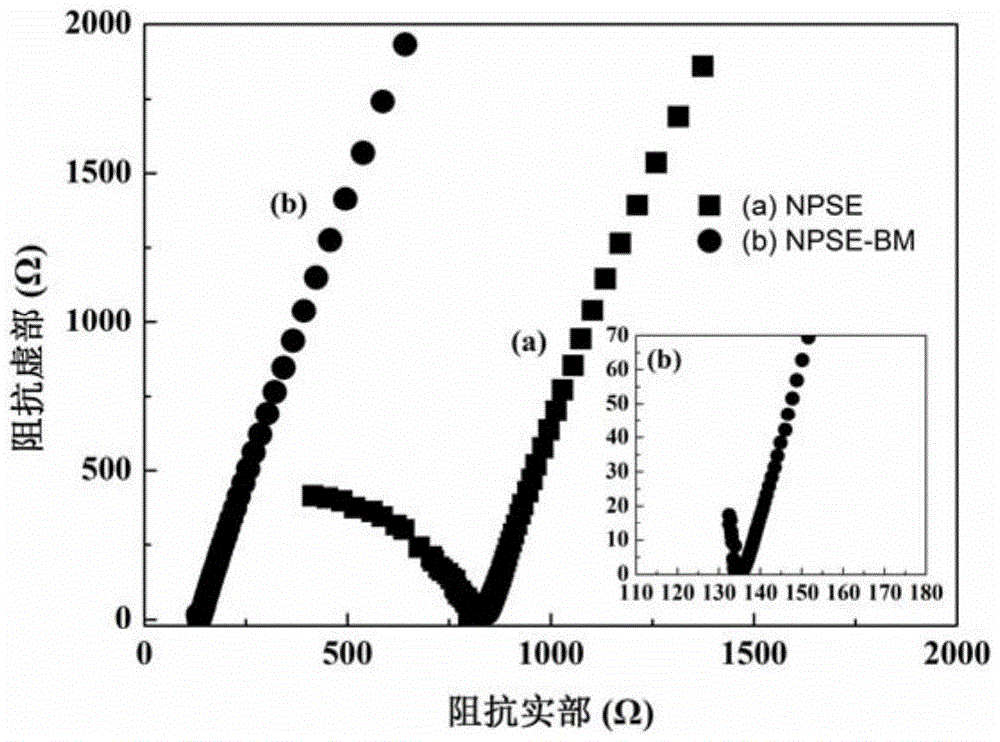

[0025] Elemental Na (>99%), P (red phosphorus, 99.999%), Se (99.999%) were weighed in the glove box according to the molar ratio Na:P:Se=3:1:4, and put into an alumina crucible , put the crucible into a quartz tube with one end closed, evacuate to 0.1Pa, and sinter the quartz tube. Then put the sealed quartz tube after firing into a muffle furnace, heat it up to 850°C at a heating rate of 0.2°C / min, keep it warm for 24 hours, and finally take out the oil and cool it to room temperature. The cooled block is taken out from the quartz tube and put into a ball mill for ball milling. The rotating speed of the ball mill is 160 rpm, and the ball milling time is 6 hours. The ball mill jar and the balls are preferably stainless steel, and the ball mill is carried out under the protection of high-purity argon (99.999%). Adopt the X-ray diffraction test method test described in embodiment 1 to test, as Figure 4 As shown, the curve shows that the as-prepared sample is a pure cubic phas...

Embodiment 3

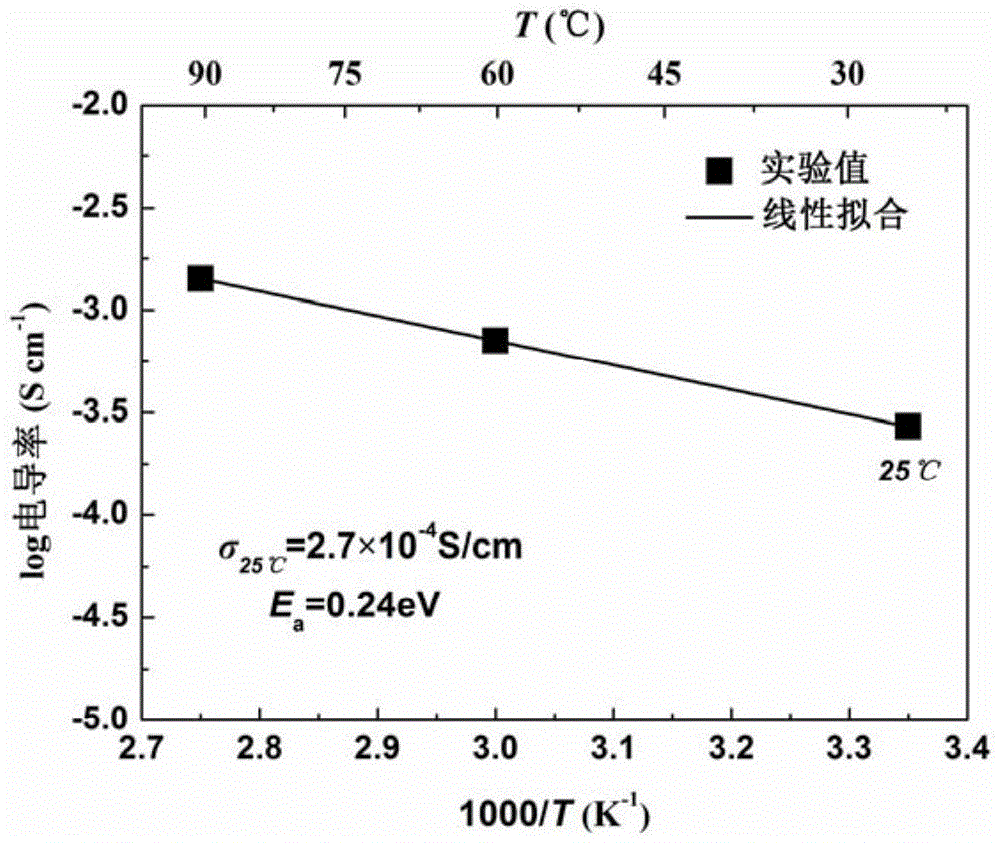

[0029] Elemental Na (>99%), P (red phosphorus, 99.999%), Se (99.999%) were weighed in the glove box according to the molar ratio Na:P:Se=3:1.1:4.1, and put into a zirconia crucible Put the crucible into a quartz tube with one end closed, evacuate to 0.1Pa, and seal the quartz tube. Put the sealed quartz tube after firing into the muffle furnace, heat it up to 900°C at a rate of 0.2°C / min, keep it warm for 24 hours, and finally take it out and cool it to room temperature in the air outside the furnace. The cooled block is taken out from the quartz tube and put into a ball mill for ball milling. The rotating speed of the ball mill is 200 rpm, and the ball milling time is 4 hours. The ball mill jar and the balls are preferably stainless steel, and the ball mill is carried out under the protection of high-purity argon (99.999%). The prepared sample was tested by X-ray diffraction as pure cubic Na 3 PSe 4 . Adopt the AC impedance test method described in embodiment 2, draw its ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity at room temperature | aaaaa | aaaaa |

| Conductivity at room temperature | aaaaa | aaaaa |

| Conductivity at room temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com