Preparation method of porous fiber gel polymer electrolyte

A gel polymer, porous fiber technology, applied in the direction of organic electrolytes, non-aqueous electrolytes, circuits, etc., to overcome the low adsorption rate, improve mechanical properties, and good application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

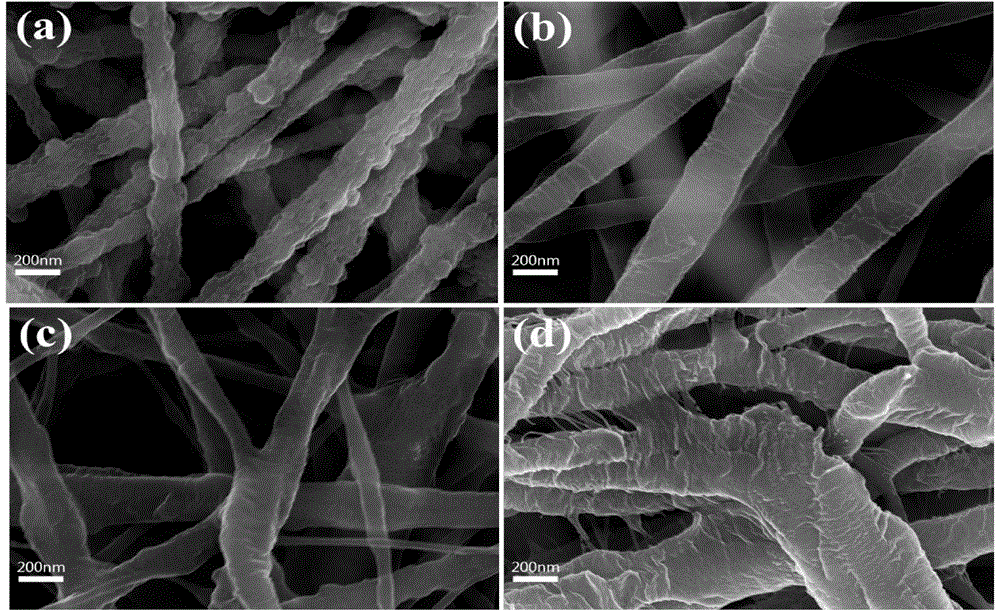

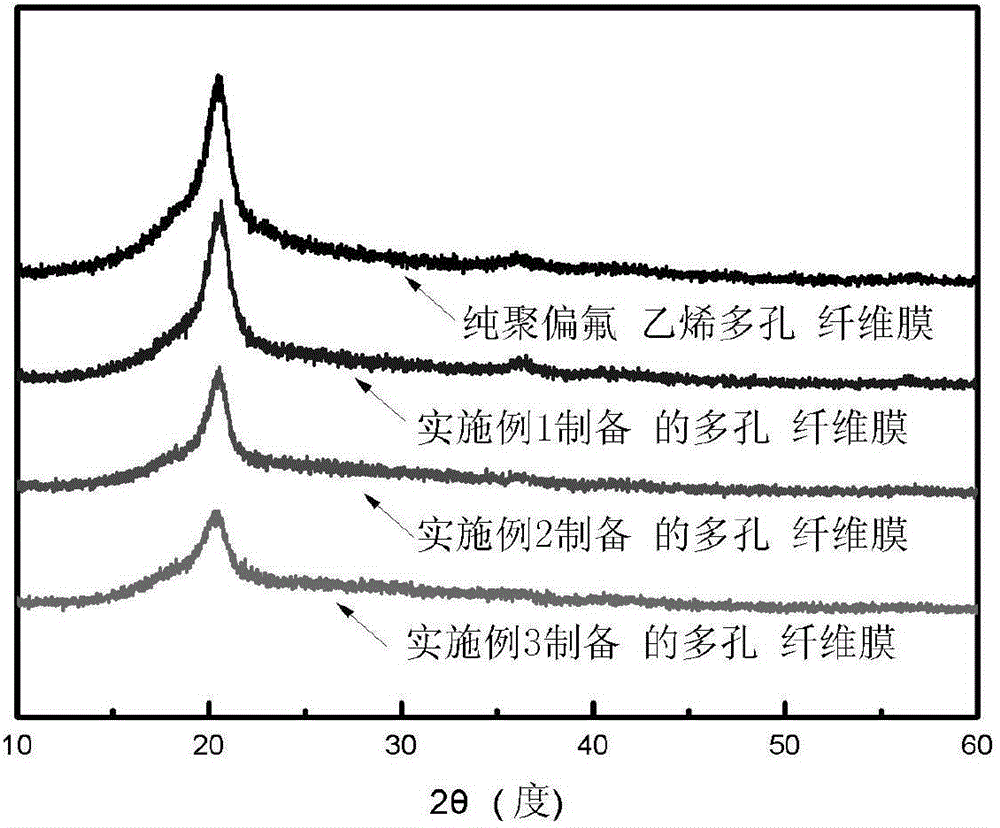

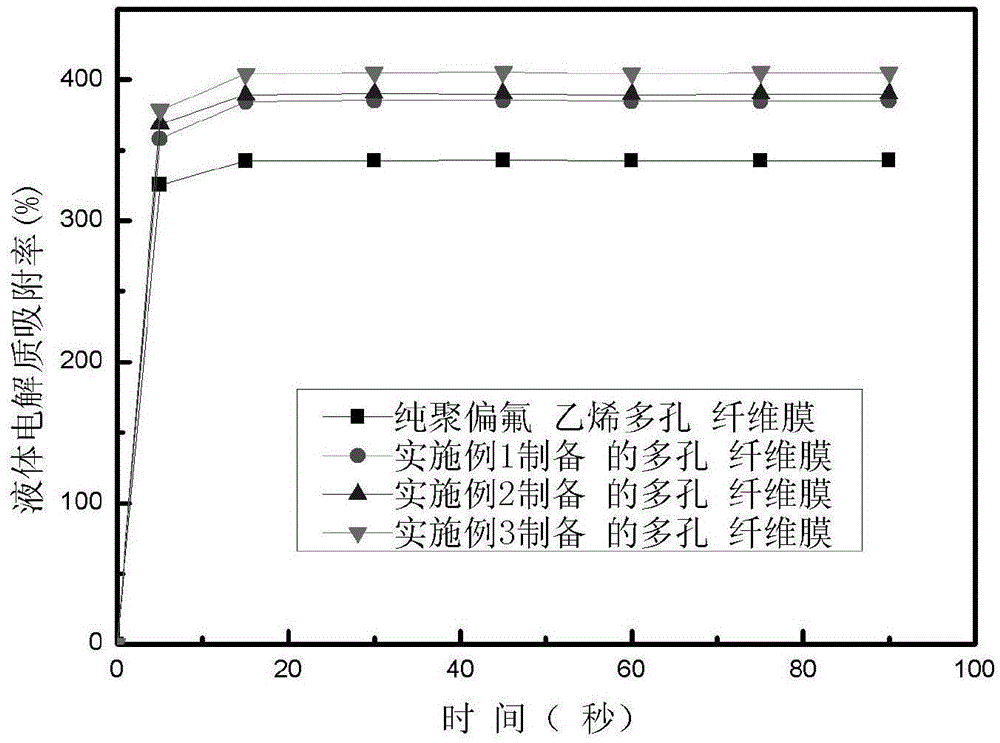

Embodiment 1

[0024] A kind of preparation method of porous fiber gel polymer electrolyte, concrete steps are:

[0025] 1. Mix polyethylene glycol with an average molecular weight of 8000 and toluene diisocyanate in a tetrahydrofuran solvent at a molar ratio of 1:2.2. The solution concentration of the mixture is controlled at 1 g / ml, and the temperature is raised to 90°C for 24 hours of condensation reaction. Then add lithium hydroxide in an equimolar amount to polyethylene glycol to the reaction system at a temperature of 65°C, neutralize the reaction for 2 hours, and then heat in an oven at 90°C for 12 hours to volatilize the solvent to obtain an ionic polymer, namely polyamino Lithium polyethylene glycol formate;

[0026] 2. Combine the obtained poly(ethylene glycol) polycarbamate lithium with a molecular weight of 1×10 5 The polyvinylidene fluoride was mixed and dispersed in the N,N-dimethylformamide solution according to the mass ratio of 1:4. The concentration of the mixture solution...

Embodiment 2

[0029] A kind of preparation method of porous fiber gel polymer electrolyte, concrete steps are:

[0030] 1. Mix polyethylene glycol with an average molecular weight of 5000 and toluene diisocyanate in a tetrahydrofuran solvent at a molar ratio of 1:2.1. The solution concentration of the mixture is controlled at 3g / ml, and the temperature is raised to 70°C for 18 hours of condensation reaction. Then add lithium hydroxide in an equimolar amount to polyethylene glycol to the reaction system at a temperature of 70°C, neutralize for 1.5 hours, and then heat in an oven at 80°C for 8 hours to volatilize the solvent to obtain an ionic polymer, namely polyamino Lithium polyethylene glycol formate;

[0031] 2. Combine the obtained poly(ethylene glycol) polycarbamate lithium with a molecular weight of 4×10 5 The polyvinylidene fluoride was mixed and dispersed in the N,N-dimethylformamide solution according to the mass ratio of 1:2. The concentration of the mixture solution was controll...

Embodiment 3

[0034] A kind of preparation method of porous fiber gel polymer electrolyte, concrete steps are:

[0035]1. Mix polyethylene glycol with an average molecular weight of 1000 and toluene diisocyanate in a tetrahydrofuran solvent at a molar ratio of 1:2. The solution concentration of the mixture is controlled at 5g / ml, and the temperature is raised to 50°C for 12 hours of condensation reaction. Then add lithium hydroxide in an equimolar amount to polyethylene glycol to the reaction system at a temperature of 75°C, neutralize for 1 hour, and then heat in an oven at 70°C for 6 hours to volatilize the solvent to obtain an ionic polymer, namely polyamino Lithium polyethylene glycol formate;

[0036] 2. Combine the obtained poly(ethylene glycol) polycarbamate lithium with a molecular weight of 5×10 5 The polyvinylidene fluoride was mixed and dispersed in the N,N-dimethylformamide solution according to the mass ratio of 1:1. The concentration of the mixture solution was controlled at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com