Method for producing protein feed raw materials by carrying out enzymolysis and fermentation on white spirit vinasse

A protein feed and distiller's grain technology, which is applied in animal feed, animal feed, application, etc., can solve the problems of long fermentation time, small output, difficulty in achieving scale and mechanization, and achieve short fermentation cycle, low cost, and improved The effect of immunity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

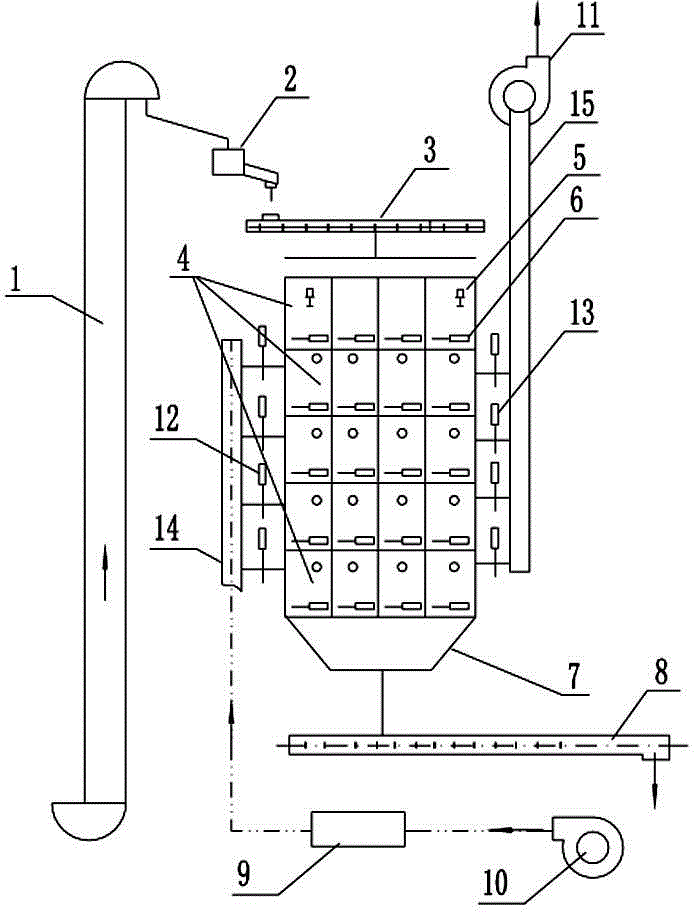

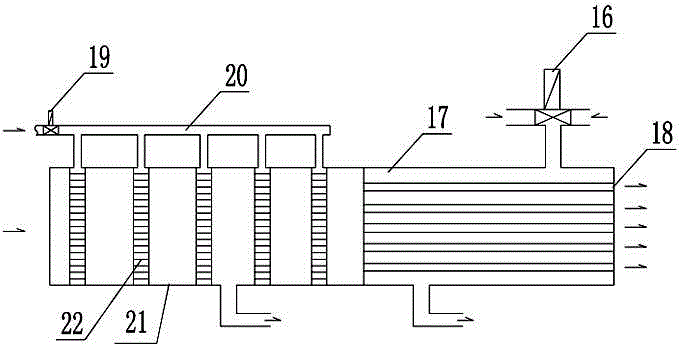

Image

Examples

Embodiment 1

[0052] The method for producing protein feed raw material by enzymatic hydrolysis and fermentation of distiller's grains of the present invention comprises the following steps:

[0053] The first step, liquid fermentation to prepare mixed bacterial liquid

[0054] The specific preparation method of Candida tropicalis fermented liquid, Bacillus natto fermented liquid, Lactobacillus plantarum fermented liquid is the same as described in the specific embodiment, and it is standby to make mixed bacterial liquid by the ratio of 2:1:1;

[0055] The second step, solid enzymatic hydrolysis and fermentation

[0056] a. Mix the distiller's grains raw material and CaO in a ratio of 100:1 and put them into the detonation cylinder evenly. The filling coefficient is 60~80%. After maintaining for 5 minutes, immediately open the pneumatic valve for steam explosion;

[0057] b. Mix the gas-exploded material, mixed bacterial solution and corn steep liquor in the mixer at a weight ratio of...

Embodiment 2

[0064] The method for producing protein feed raw material by enzymatic hydrolysis and fermentation of distiller's grains of the present invention comprises the following steps:

[0065] The first step, liquid fermentation to prepare mixed bacterial liquid

[0066] The specific preparation method of Candida tropicalis fermented liquid, Bacillus natto fermented liquid, Lactobacillus plantarum fermented liquid is the same as described in the specific embodiment, and it is made into mixed bacterial liquid in the ratio of 1:1:1 for subsequent use;

[0067] The second step, solid enzymatic hydrolysis and fermentation

[0068] a. Mix the distiller's grains raw material and CaO in a ratio of 80:1 and put them into the detonation cylinder evenly. The filling coefficient is 60~80%. After maintaining for 10 minutes, immediately open the pneumatic valve for steam explosion;

[0069] b. Mix the gas-exploded material, mixed bacterial solution and corn steep liquor in a mixer at a weig...

Embodiment 3

[0076] The method for producing protein feed raw material by enzymatic hydrolysis and fermentation of distiller's grains of the present invention comprises the following steps:

[0077] The first step, liquid fermentation to prepare mixed bacterial liquid

[0078] The specific preparation method of Candida tropicalis fermented liquid, Bacillus natto fermented liquid, Lactobacillus plantarum fermented liquid is the same as described in the specific embodiment, and it is standby to make mixed bacterial liquid by the ratio of 2:2:1;

[0079] The second step, solid enzymatic hydrolysis and fermentation

[0080] a. Mix the distiller's grains raw material and CaO in a ratio of 60:1 and put them into the detonation tank evenly. The filling coefficient is 60~80%. After maintaining for 1min, immediately open the pneumatic valve for steam explosion;

[0081] b. Mix the gas-exploded material, mixed bacterial liquid and corn steep liquor in a mixer at a weight ratio of 1:0.5:1.0, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com