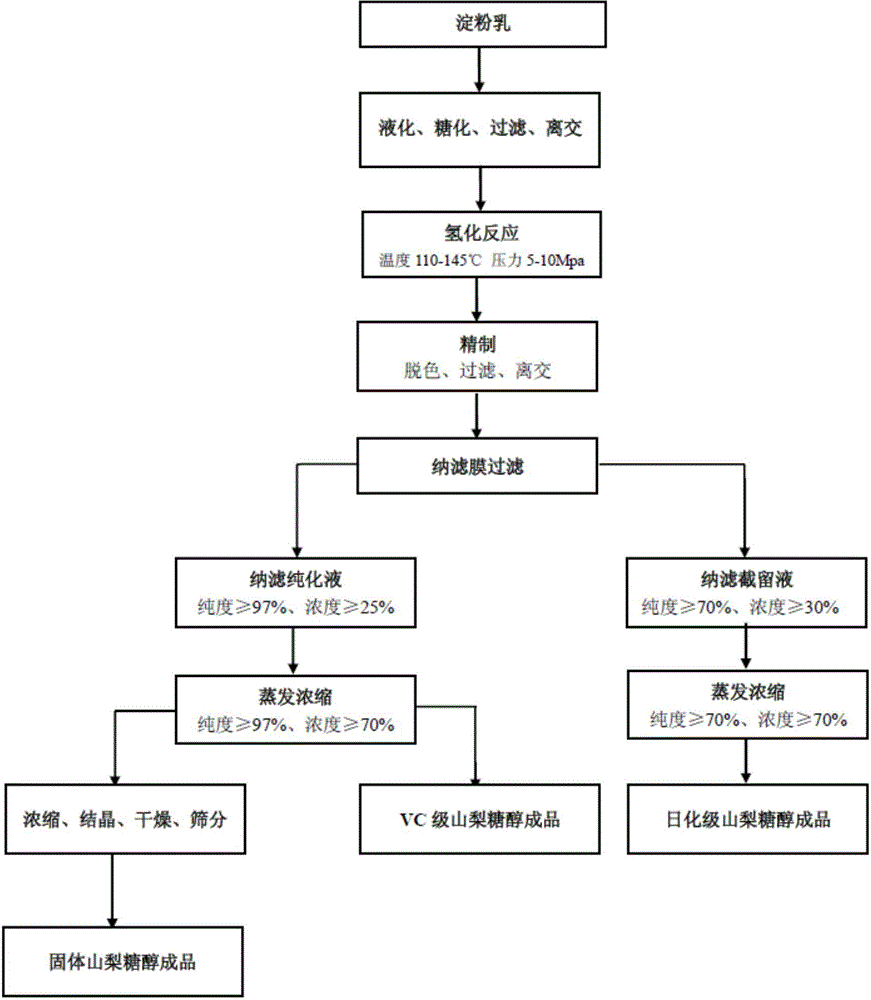

Method for preparing high-purity sorbitol and daily-chemical-grade sorbitol

A technology of sorbitol and daily chemical grade, which is applied in the field of preparing high-purity sorbitol and daily chemical grade sorbitol, which can solve the problems of complex process, large equipment investment and production cost, and achieve simple production process and high raw material utilization rate The effect of high and low equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] (1) Starch is formulated into starch milk of 20 degrees Baume (°Bé), and it is 10% Na with mass percent concentration. 2 CO 3 The solution adjusts the pH value of the starch milk to 5.8. Calculated on the basis of the dry matter of the starch milk, add 400g / t of high-temperature-resistant α-amylase (purchased from Novozymes, Liquozyme Supra), and heat at 108°C Liquefaction is carried out to obtain a liquefied liquid.

[0041] (2) The pH value of the liquefied liquid is adjusted to 4.2 with hydrochloric acid with a mass fraction of 30%. Calculated on the dry matter of starch milk, add 450g / t compound enzyme preparation (purchased from Novozymes, trade name: DextrozymeDX), at 60 Saccharification at ℃ for 48 hours to obtain a saccharification solution with a glucose purity of 95.5%.

[0042] (3) First use a vacuum drum filter to filter the saccharification solution to remove protein, add 0.2% activated carbon according to the dry matter of starch milk, and decolorize at ...

Embodiment 2

[0049] (1) Starch is mixed with the starch milk of 20.5 degrees of Baume (°B é), and it is 10% Na with mass percent concentration 2 CO 3 The pH value of the starch milk was adjusted to 6.0 by the solution. Calculated based on the dry matter of the starch milk, 400 g / t of high temperature-resistant α-amylase (purchased from Novozymes, Liquozyme Supra) was added, and the temperature was increased at 108°C. Liquefaction is carried out to obtain a liquefied liquid.

[0050] (2) The pH value of the liquefied liquid is adjusted to 4.3 with hydrochloric acid with a mass fraction of 30%. Calculated on the dry matter of starch milk, add 460g / t compound enzyme preparation (purchased from Novozymes, trade name: DextrozymeDX), at 60 Saccharification at °C for 48 hours to obtain a saccharification solution with a glucose purity of 95.8%.

[0051] (3) First filter the saccharification solution with a plate and frame filter to remove protein, add 0.2% activated carbon according to the dry ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com