Automobile hub bearing seal ring and manufacturing technique thereof

A technology for bearing seals and automotive hubs, applied in the field of automotive hub bearing sealing rings and its manufacturing process, can solve the problems of unbearable sealing rings, poor high temperature resistance, and no manufacturing process, etc., and achieve stable structure, good product quality, and shortened The effect of production time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

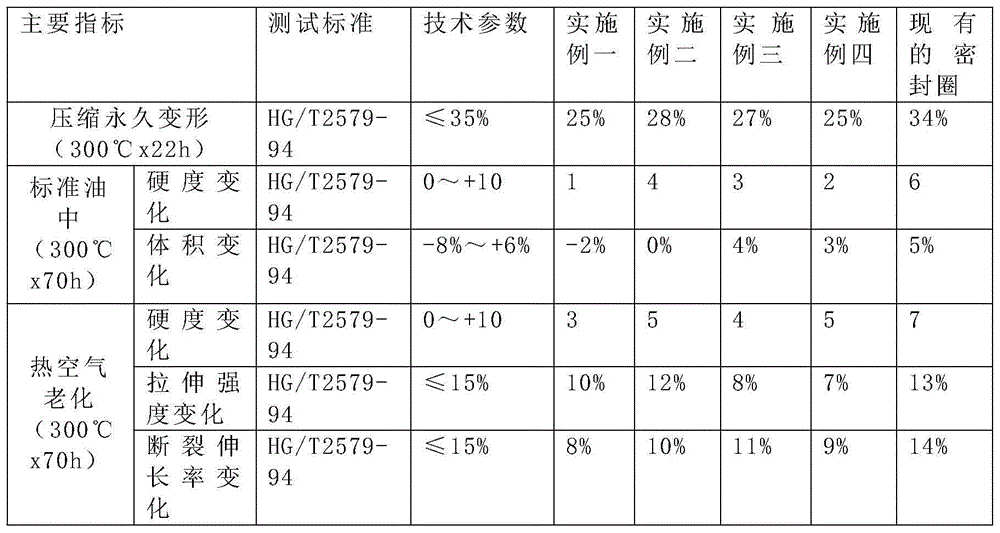

Examples

Embodiment 1

[0029] The automobile hub bearing sealing ring, including nitrile rubber, sulfur, anti-aging agent 4010, zinc oxide, stearic acid, calcium hydroxide, aluminum oxide powder, dibutyl phthalate, silicon dioxide and diatomaceous earth, each The components are as follows by mass percentage: nitrile rubber accounts for 70%-80%, sulfur accounts for 10%-20%, anti-aging agent 4010 accounts for 1%-3%, zinc oxide accounts for 0.5%-0.8%, stearic acid accounts for 2%- 4%, calcium hydroxide 1%-5%, alumina powder 0.2%-0.6%, dibutyl phthalate 0.1%-0.3%, silicon dioxide 3%-7%, and diatomaceous earth Accounting for 1%-4%, the sum of each component is 100%.

[0030] Nitrile rubber accounted for 70%, sulfur accounted for 10%, antioxidant 4010 accounted for 3%, zinc oxide accounted for 0.6%, stearic acid accounted for 4%, calcium hydroxide accounted for 3%, alumina powder accounted for 0.2%, phthalic acid Dibutyl ester 0.2%, silica 7% and diatomaceous earth 2%.

Embodiment 2

[0032] The automobile hub bearing sealing ring, including nitrile rubber, sulfur, anti-aging agent 4010, zinc oxide, stearic acid, calcium hydroxide, aluminum oxide powder, dibutyl phthalate, silicon dioxide and diatomaceous earth, each The components are as follows by mass percentage: nitrile rubber accounts for 70%-80%, sulfur accounts for 10%-20%, anti-aging agent 4010 accounts for 1%-3%, zinc oxide accounts for 0.5%-0.8%, stearic acid accounts for 2%- 4%, calcium hydroxide 1%-5%, alumina powder 0.2%-0.6%, dibutyl phthalate 0.1%-0.3%, silicon dioxide 3%-7%, and diatomaceous earth Accounting for 1%-4%, the sum of each component is 100%.

[0033] Nitrile rubber accounted for 72%, sulfur accounted for 10%, antioxidant 4010 accounted for 3%, zinc oxide accounted for 0.6%, stearic acid accounted for 3%, calcium hydroxide accounted for 1%, alumina powder accounted for 0.2%, phthalic acid Dibutyl ester 0.2%, silica 6% and diatomaceous earth 3%.

Embodiment 3

[0035] The automobile hub bearing sealing ring, including nitrile rubber, sulfur, anti-aging agent 4010, zinc oxide, stearic acid, calcium hydroxide, aluminum oxide powder, dibutyl phthalate, silicon dioxide and diatomaceous earth, each The components are as follows by mass percentage: nitrile rubber accounts for 70%-80%, sulfur accounts for 10%-20%, anti-aging agent 4010 accounts for 1%-3%, zinc oxide accounts for 0.5%-0.8%, stearic acid accounts for 2%- 4%, calcium hydroxide 1%-5%, alumina powder 0.2%-0.6%, dibutyl phthalate 0.1%-0.3%, silicon dioxide 3%-7%, and diatomaceous earth Accounting for 1%-4%, the sum of each component is 100%.

[0036] Nitrile rubber accounted for 78%, sulfur accounted for 10%, antioxidant 4010 accounted for 1%, zinc oxide accounted for 0.6%, stearic acid accounted for 3%, calcium hydroxide accounted for 1%, alumina powder accounted for 0.2%, phthalic acid Dibutyl ester 0.2%, silica 4% and diatomaceous earth 2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com