Method for normal temperature and pressure whole-wet leaching of toxic elements in mining and metallurgical solid waste

A technology for toxic elements and solid waste, applied in the field of full wet leaching of toxic elements in mining and metallurgical solid waste at room temperature and pressure, can solve the problems of high treatment cost, inability to achieve zero pollution discharge of sewage, inability to effectively separate toxic elements, etc. Achieve the effect of improving leaching efficiency, realizing resource utilization and harmless utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

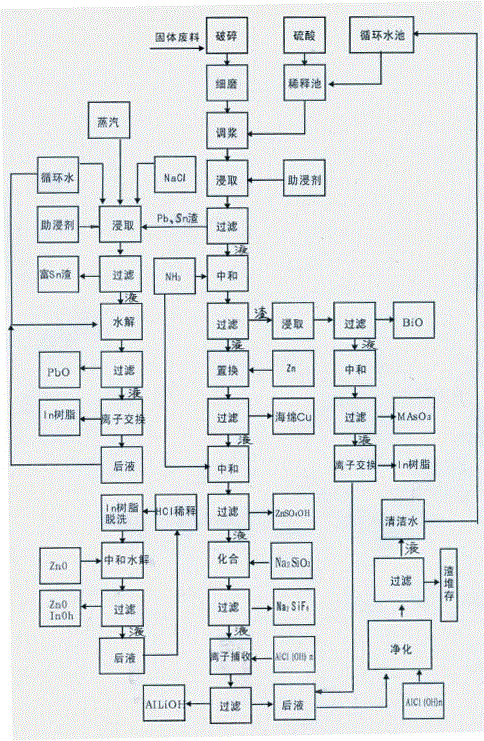

Image

Examples

Embodiment Construction

[0038] Below in conjunction with accompanying drawing and example further illustrate the present invention.

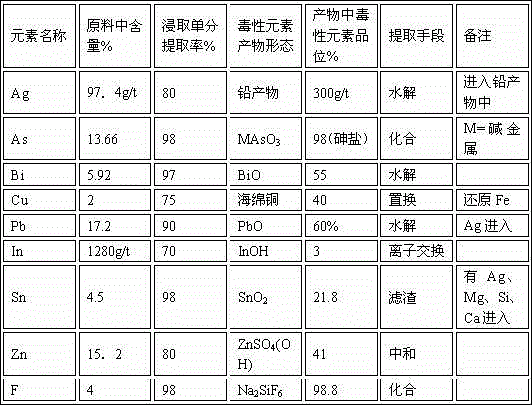

[0039] Example 1. Where the applicant is located, the smelting dust of a copper company in Yunnan is a solid waste containing various toxic elements. In the past, the traditional acid leaching process was used for treatment, and only 1-3 kinds of toxic elements could be recovered, and the process was long, with many procedures, and the extraction cost was high. The waste residue also contained a large amount of toxic elements, which had potential pollution to the environment and could not be achieved. Non-toxic and harmless discharge.

[0040] Specifically, the existing technology roughly divides the leaching of such solid waste into two stages, the first stage leaching As40%, Zn50%, In30%, Bi10%, Cu20% in the immersion liquid, and neutralizing pH=8-8.5 with CaOH , and then settling all the leachate, filtering, the slag is landfilled as solid waste, and the liquid is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com