Laying method of seed crystals, preparation method of quasi-monocrystalline silicon piece and quasi-monocrystalline silicon piece

A laying method and quasi-single crystal technology, which are applied in the directions of single crystal growth, single crystal growth, chemical instruments and methods, etc. Dislocation source and other problems, to achieve the effect of simple and easy operation of the laying method, reducing lattice mismatch stress, and reducing the probability of dislocation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

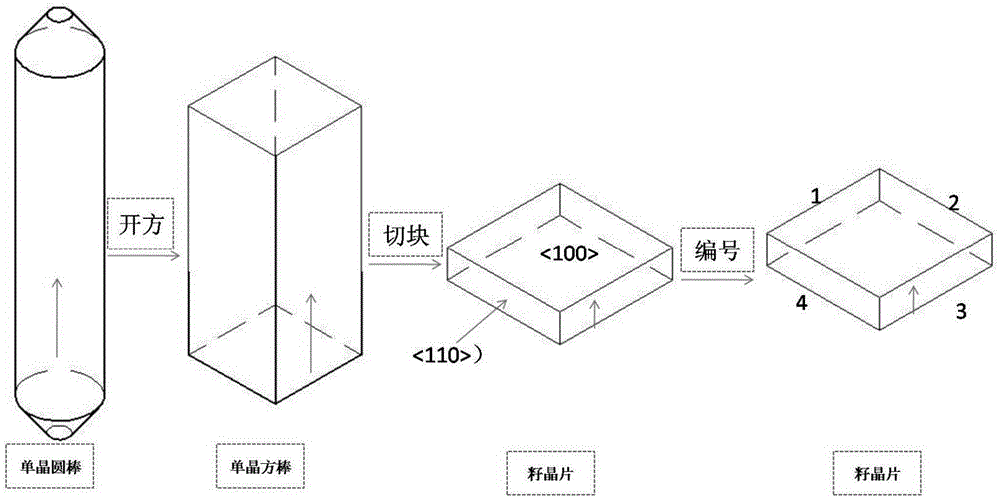

[0075] A method for laying a seed crystal, which is used for the casting of a quasi-single crystal, comprises the following steps:

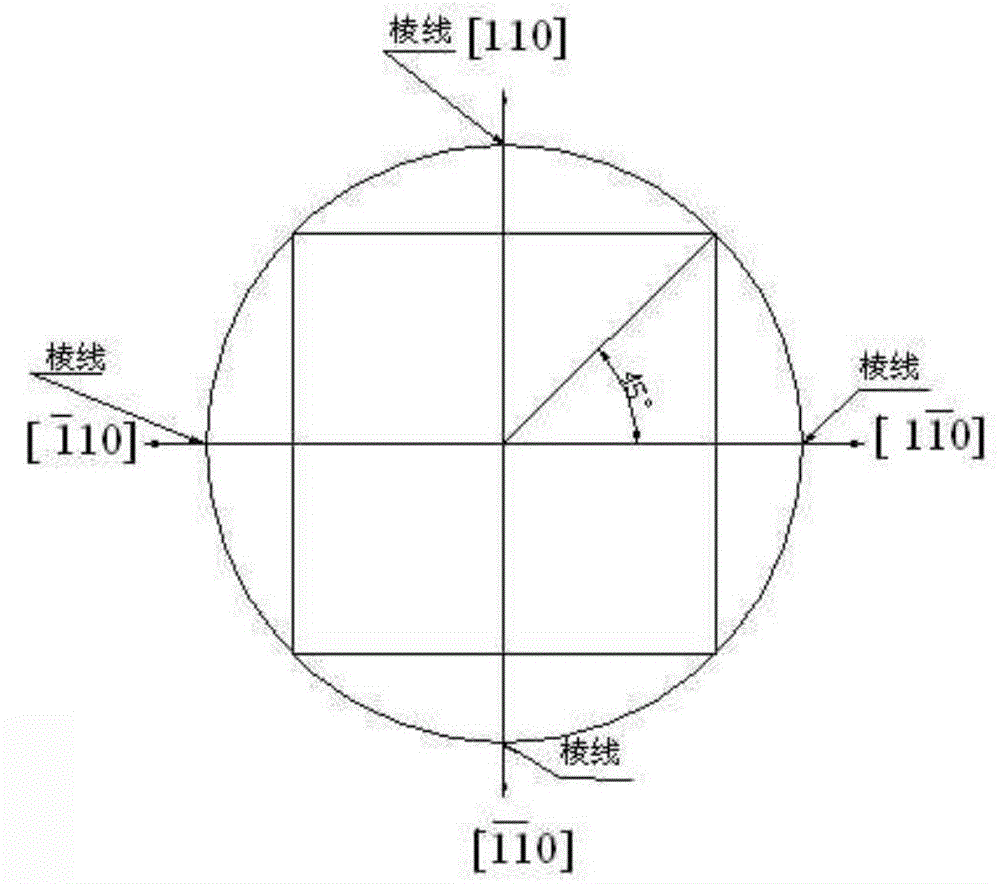

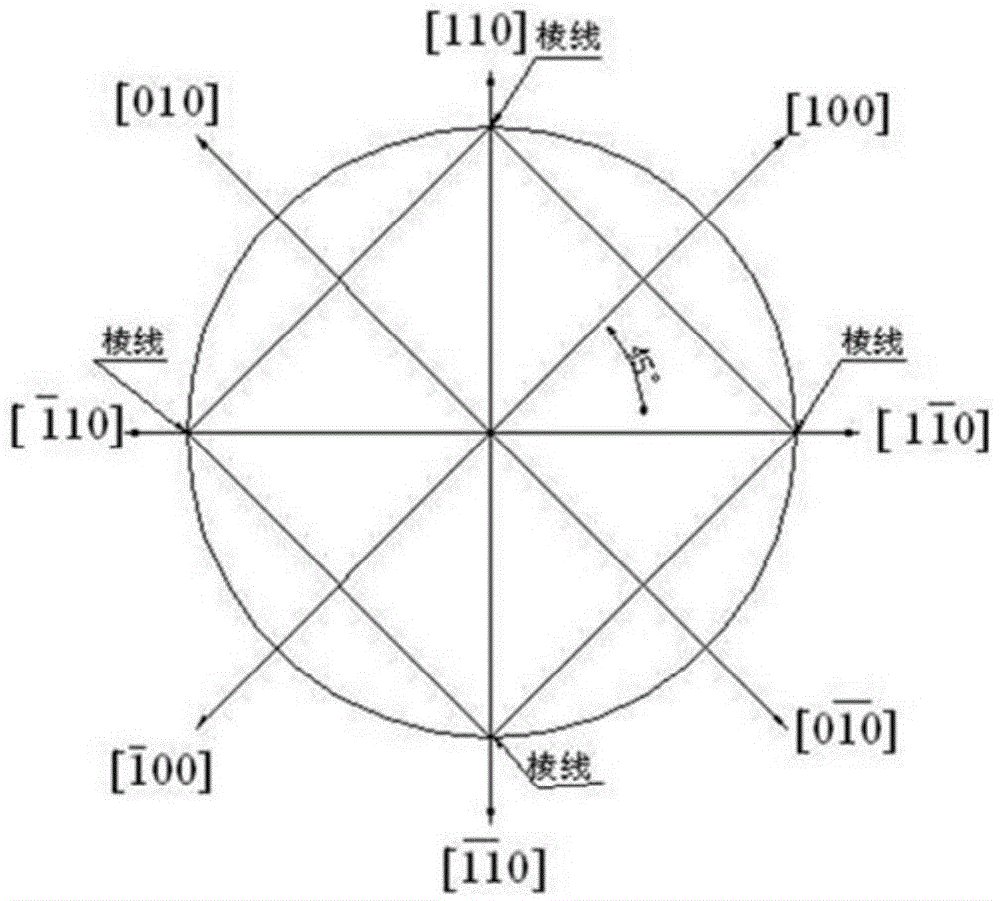

[0076] Select a square seed crystal with a crystal orientation of on the growth surface and on the side surface as the target growth seed crystal, and the numbering method is as follows figure 1 As shown, wherein, the seed crystals are derived from the same single crystal rod, the thickness of the seed crystals is 20mm, and 25 pieces of the seed crystals with a cross-sectional size of 156mm*156mm are spread on the bottom of the crucible in a 5×5 manner, and the seed crystals are The crystal growth face of the crystal is [001] with the same positive direction, and then one of the adjacent seed crystals is turned 180° around the normal direction of the contact side of the seed crystal, or one of the adjacent seed crystals is Flip 180° around the direction perpendicular to the normal direction of the contact side of the seed crystal. At this time,...

Embodiment 2

[0081] A method for laying a seed crystal, which is used for the casting of a quasi-single crystal, comprises the following steps:

[0082] Select a square seed crystal with a crystal orientation of on the growth surface and on the side surface as the target growth seed crystal, and the numbering method is as follows figure 1As shown, wherein, the seed crystals are derived from the same single crystal rod, the thickness of the seed crystals is 20mm, and 25 pieces of the seed crystals with a cross-sectional size of 156mm*156mm are spread on the bottom of the crucible in a 5×5 manner, and the seed crystals are The crystal orientation of the growth surface of the crystal is the same as [001], and then one of the adjacent seed crystals is rotated by 90°. At this time, the crystal orientation of the contact side of the two adjacent seed crystals belongs to the other crystal orientation group of the same crystal orientation group. crystal orientation, and the contact side surfaces...

Embodiment 3

[0088] A method for laying a seed crystal, which is used for the casting of a quasi-single crystal, comprises the following steps:

[0089] Select the crystallographic orientation of the growth plane as The square seed crystal with side crystal direction is used as the target growth seed crystal, and the numbering method is as follows figure 1 As shown, wherein, the seed crystals are derived from the same single crystal rod, the thickness of the seed crystals is 20mm, and 25 pieces of the seed crystals with a cross-sectional size of 156mm*156mm are spread on the bottom of the crucible in a 5×5 manner, and the seed crystals are The growth planes of the crystals are all opposite Then rotate one of the adjacent seed crystals by 90° (at this time, the adjacent seed crystals are laid on the opposite side), and at this time, the crystal orientations of the contact sides of the two adjacent seed crystals belong to different crystal orientations of the same crystal plane family i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com