Addition type silicone rubber impression material

An impression material and silicone rubber technology, which is applied in the field of addition-type silicone rubber impression materials, can solve the problems of poor detail reproducibility and achieve the effect of improving hydrophobicity, good detail reproducibility, and accurate impression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

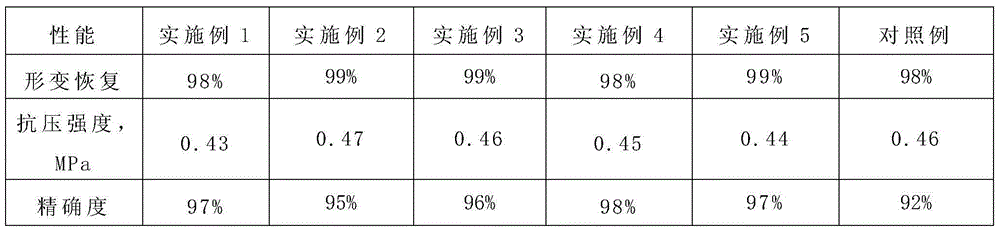

Examples

Embodiment 1

[0016] Addition-type silicone rubber impression material, including the following raw materials in parts by mass: 25 parts of vinyl polydimethylsiloxane, 1 part of hydrogen-containing silicone oil, 1 part of catalyst vinylsiloxane platinum complex, reinforced 3 parts of white carbon black as agent, 55 parts of quartz powder as compatibilizer, 0.1 part of dimethyldichlorosilane as hydrophilic modifier, 1 part of nonylphenol polyoxyethylene ether as nonionic surfactant, 0.1 part of indophenol, benzene 0.1 part of alkyl formate, 0.1 part of pigment, 0.1 part of peppermint oil.

[0017] Mix the above components evenly with an electric mixer, mix at a speed of 160r / min for 10min, and then vacuumize and defoam for 30min to obtain the addition-type silicone rubber impression material described in this example.

Embodiment 2

[0019] Addition-type silicone rubber impression material, including the following raw materials in parts by mass: 28 parts of vinyl polydimethylsiloxane, 3 parts of hydrogen-containing silicone oil, 2 parts of catalyst vinylsiloxane platinum complex, reinforced 5 parts of white carbon black as agent, 58 parts of quartz powder as compatibilizer, 0.5 part of trimethylethoxysilane as hydrophilic modifier, 1.2 parts of nonylphenol polyoxyethylene ether as nonionic surfactant, 0.2 part of indophenol, 0.3 part of alkyl benzoate, 0.2 part of pigment, 0.4 part of peppermint oil.

[0020] Mix the above components evenly with an electric mixer, mix at a speed of 160r / min for 10min, and then vacuumize and defoam for 30min to obtain the addition-type silicone rubber impression material described in this example.

Embodiment 3

[0022] Addition-type silicone rubber impression material, including the following raw materials in parts by mass: 30 parts of vinyl polydimethylsiloxane, 5 parts of hydrogen-containing silicone oil, 3 parts of catalyst vinylsiloxane platinum complex, reinforced Agent MQ silicone resin 6 parts, compatibilizer quartz powder 60 parts, hydrophilic modifier polydimethylsiloxane 1 part, nonionic surfactant nonylphenol polyoxyethylene ether 1.5 parts, indophenol 0.3 parts, 0.5 part of alkyl benzoate, 0.5 part of pigment, 0.8 part of peppermint oil.

[0023] Mix the above components evenly with an electric mixer, mix at a speed of 160r / min for 10min, and then vacuumize and defoam for 30min to obtain the addition-type silicone rubber impression material described in this example.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com