Preparation method of magnetic carbon nanocomposite

A nanocomposite material and magnetic nanotechnology, applied in the field of preparation of magnetic carbon nanocomposite materials, can solve the problems of pore volume reduction, blockage of pore space, reduction of specific surface area, etc., and achieve good adsorption effect and simple and rapid separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

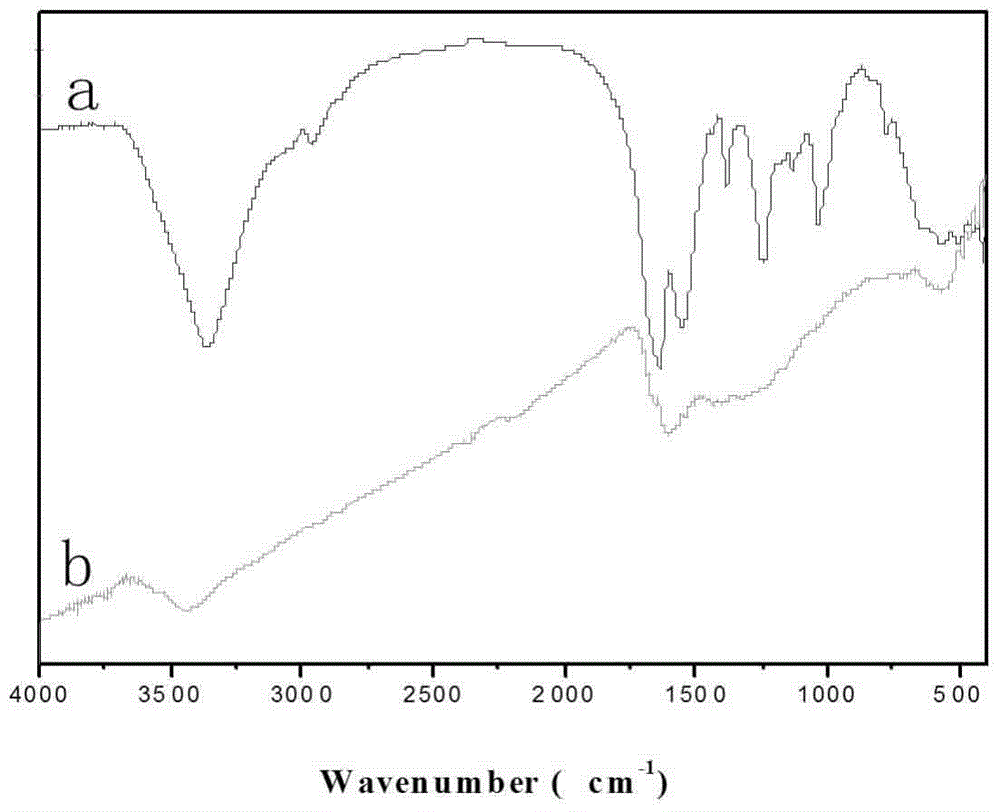

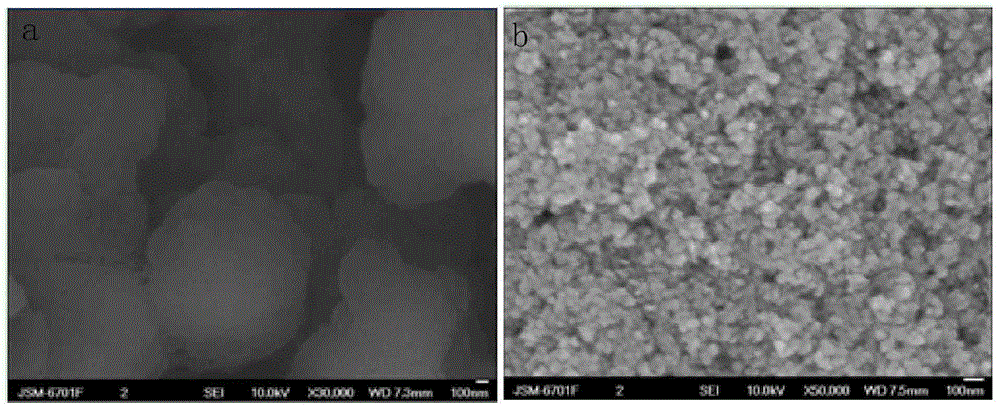

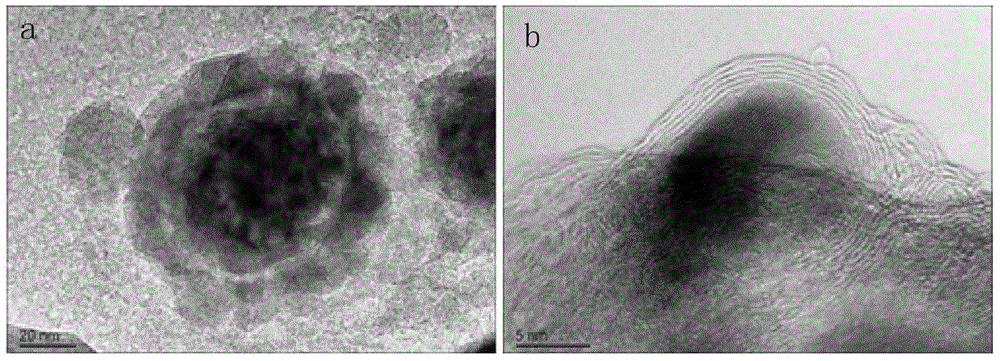

[0028] The preparation method of embodiment 1 magnetic carbon nanocomposite material

[0029] (1) Preparation method

[0030] 1) Weigh FeCl 3 and FeCl 2(molar ratio is 2:1), dissolved in deionized water, adjusted to pH = 9 with 0.5mol / L ammonia water, mechanically stirred for 0.5h at 90°C, filtered with suction, washed with deionized water until neutral, and dried in vacuum , to obtain black crystal Fe 3 o 4 Nanoparticles.

[0031] 2) Weigh 0.4g polyvinyl alcohol, add 20mL deionized water, heat to 90°C until completely dissolved, then add 0.1g Fe 3 o 4 Nanoparticles, stirred mechanically for 3h, obtained Fe modified by polyvinyl alcohol 3 o 4 Nanoparticles.

[0032] 3) Mix urea and formaldehyde at a molar ratio of 1:3 (the urea is 1.5g), add 15mL of deionized water, adjust the pH to 8 with NaOH, stir magnetically, and prepolymerize at room temperature for 3h. Then adjust to pH=5 with HCl, add polyvinyl alcohol modified Fe 3 o 4 Nanoparticles, stirred at room temper...

Embodiment 2

[0040] The preparation method of embodiment 2 magnetic carbon nanocomposites

[0041] 1) Weigh FeCl 3 and FeCl 2 (molar ratio is 2:1), dissolved in deionized water, stirred mechanically, and adjusted pH=9 with 0.5mol / L ammonia water, stirred mechanically for 0.5h at 90°C, filtered with suction, washed the solid with deionized water until neutral , dried under vacuum to obtain black crystalline Fe 3 o 4 Nanoparticles.

[0042] 2) Weigh 0.4g polyvinyl alcohol, add 20mL deionized water, heat to 90°C until completely dissolved, then add 0.1g Fe 3 o 4 Nanoparticles, stirred mechanically for 3h, obtained Fe modified by polyvinyl alcohol 3 o 4 Nanoparticles.

[0043] 3) Mix urea and formaldehyde at a molar ratio of 1:3 (1.4 g of urea), add 15 mL of deionized water, adjust pH to 8 with NaOH, magnetically stir, and prepolymerize at room temperature for 3 h. Then adjust pH=5 with HCl, add polyvinyl alcohol modified Fe 3 o 4 Nanoparticles, stirred at room temperature for 18h, ...

Embodiment 3

[0045] The preparation method of embodiment 3 magnetic carbon nanocomposites

[0046] 1) Weigh FeCl 3 and FeCl 2 (molar ratio is 2:1), dissolved in deionized water, stirred mechanically, and adjusted pH=9 with 0.5mol / L ammonia water, stirred mechanically for 0.5h at 90°C, filtered with suction, washed the solid with deionized water until neutral , dried under vacuum to obtain black crystalline Fe 3 o 4 Nanoparticles.

[0047] 2) Weigh 0.3g polyvinyl alcohol, add 20mL deionized water, heat to 90°C until completely dissolved, then add 0.1g Fe 3 o 4 Nanoparticles, stirred mechanically for 3h, obtained Fe modified by polyvinyl alcohol 3 o 4 Nanoparticles.

[0048] 3) Mix urea and formaldehyde at a molar ratio of 1:3 (1.5 g of urea), add 15 mL of deionized water, adjust pH=8 with NaOH, magnetically stir, and prepolymerize at room temperature for 3 h. Then adjust pH=5 with HCl, add polyvinyl alcohol modified Fe 3 o 4 Nanoparticles, stirred at room temperature for 18h, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com