[0002] Oil pipe is one of the necessary facilities for

oil and natural gas exploitation. Traditional downhole pipe strings have corrosion and protection problems.

Corrosion is a key factor related to the normal production and operation of oil and gas wells, especially the corrosion and Anti-corrosion is even more prominent. In

oil field operations, there are often corrosive media such as

hydrogen sulfide,

sulfate-reducing

bacteria, chemical drive fluid, three-free compound drive fluid, high-temperature

oxygen,

carbon dioxide, and

chloride ions in the tubing string. There is no anti-corrosion function. Under the long-term working condition of the oil pipe, the

weld seam, the inner wall of the inner pipe, and the outer wall of the outer pipe are easily corroded by corrosive media, resulting in

cracking of the

weld seam, corrosion of the inner and outer pipes, and failure of the oil pipe

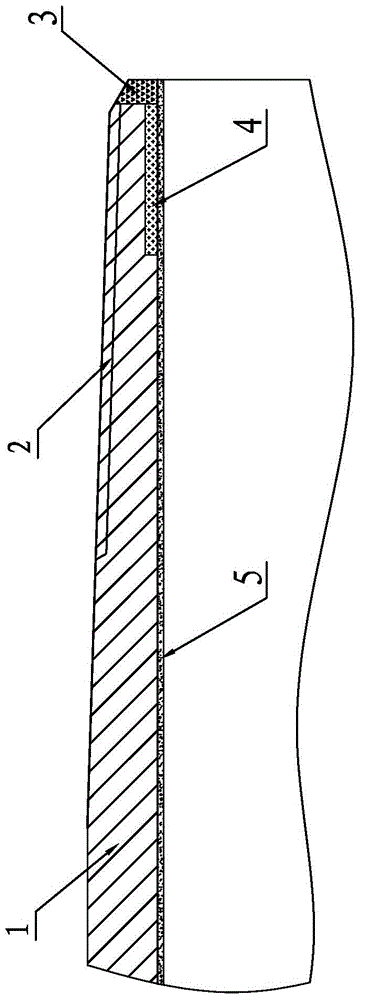

In order to prevent the corrosion of the pipe body, especially the anti-corrosion problem of the inner hole of the pipe and the connecting thread section, people have developed an anti-corrosion oil pipe coated with an organic anti-corrosion

coating on the surface of the steel pipe body, and implemented anti-corrosion protection measures for the oil pipe. This type of anti-corrosion oil pipe It can effectively protect and slow down the corrosion of the tubing string. The traditional anti-corrosion tubing string generally uses an organic anti-corrosion

coating on the inner hole of the tubing and the outer surface of the threaded connection at both ends of the pipe body. The tubing string with this structure has an anti-corrosion

coating. In the

actual use process, the anti-corrosion performance of the inner hole surface of the anti-corrosion pipe string is very good, which can effectively

resist the

erosion of the corrosive medium in the oil vapor, prevent the corrosion of the steel pipe body, and improve the service life of the pipe body. However, the two sides of the pipe body The end surface of the connecting threaded section at the end is severely corroded and corroded, and the sealing end surface is corroded and damaged in the slightest, and the entire threaded connection section is corroded in severe cases, and the pipe body is broken at the connection with the

coupling.

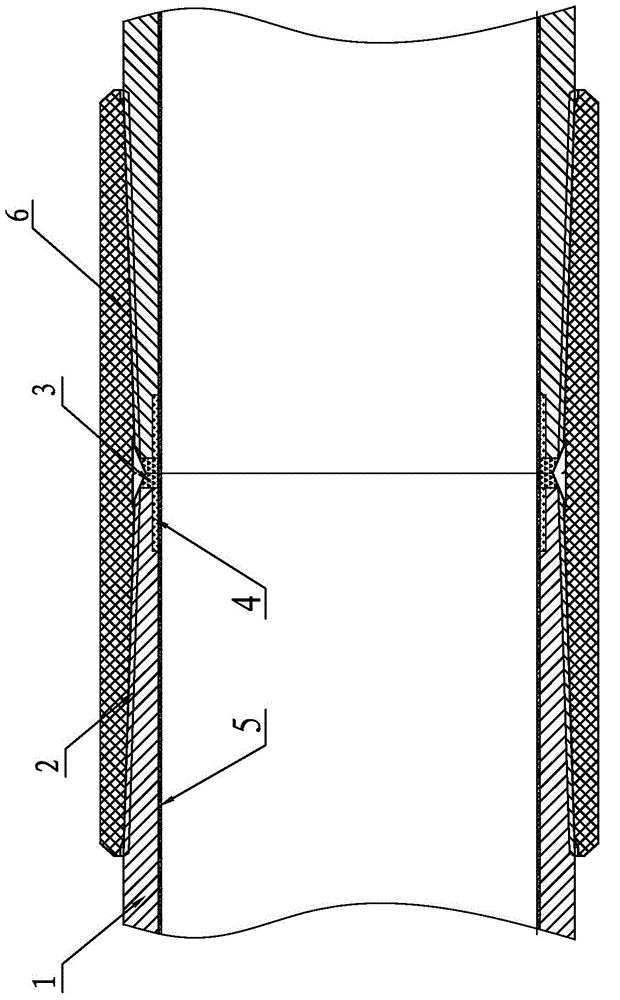

After careful dismantling and analysis by the applicant, the main reason for the above defects is that when the two pipes are connected with the

coupling, in order to ensure the original sealing performance of the end faces of the two pipes, the butt end faces of the two pipes must be screwed tightly and sealed. , during the tightening process, the connecting end faces of the two pipe bodies will inevitably produce a

rotational shear effect, causing the anti-corrosion coating on the end face of the pipe body to be torn and damaged, and in severe cases, the anti-corrosion coating will be separated from the steel pipe body. The end face of the steel pipe body originally coated with anti-corrosion coating is directly in contact with the corrosive medium, so that

pitting corrosion will inevitably occur at the joint end face of the pipe string connection or local corrosion will occur through penetration until the pipe body connection end corrodes Perforation, and then the corrosive medium will enter the threaded sealing end face for acidification corrosion, which will not only fail the original sealing

butt joint surface, but also corrode the connecting threaded section, resulting in the failure of the threaded connection sealing tape and a significant drop in connection strength

[0003] Once the above-mentioned defects appear, the anti-corrosion performance of the anti-corrosion pipe body will be greatly reduced until it fails. After a period of use, gas and liquid leakage in the pipe body will occur, resulting in the failure of the tubing string to work normally, directly affecting the development of

oil production or production. The operation of

station gathering and transportation and wet gas transportation

system may cause difficulty in well killing or obstruction of

well logging in severe cases, which shortens the service life of tubing and increases production costs

[0004] In order to effectively overcome such defects, some oil pipe manufacturers have begun to use 13Cr-110 oil pipes instead of ordinary anti-corrosion oil pipes to eliminate the corrosion problem on the end face of oil pipes. Although this solution can solve the anti-corrosion problem of oil pipes, the price of 13Cr-110 oil pipes is high. The one-time investment is too high, and the threaded connection section and the sealing end face of the pipe body are disassembled and re-screwed during use, and the connection sealing performance and reliability are difficult to guarantee. If they are discarded, the loss will be too great

The service life is not long, it is only suitable for high-quality oil and gas wells, and the scope of use is limited

Login to View More

Login to View More