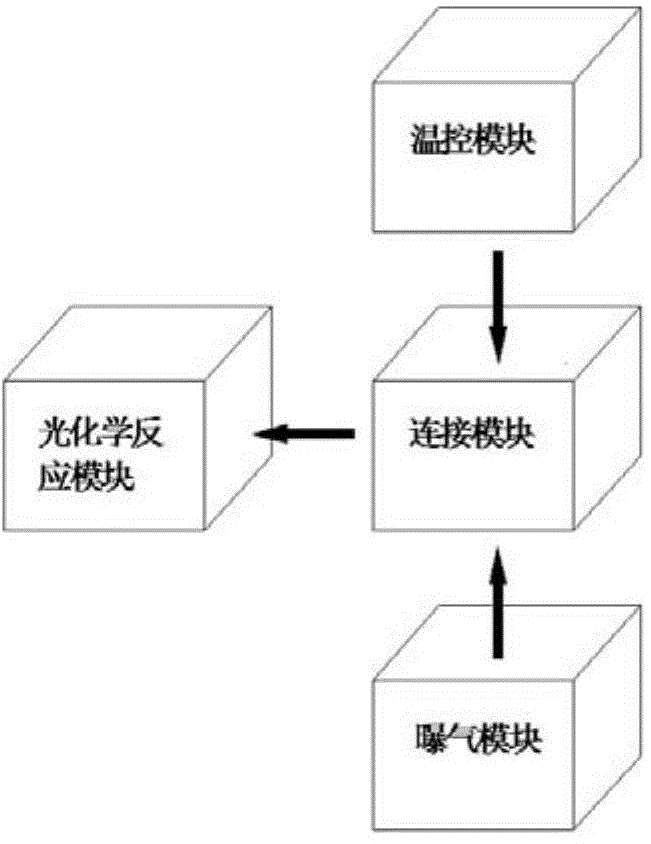

Temperature control, aeration and stirring integrated environmental pollutant photochemical transformation studying device

A technology of environmental pollutants, aeration and agitation, applied in the direction of measuring devices, scientific instruments, instruments, etc., can solve the problems of complex overall design, temperature rise of the reaction system, cost increase, etc., to improve accuracy and precision, simplify Photochemical device, effect of reducing complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0038] Add 200ml of water into the three beakers respectively, beaker 1 is aerated through the aeration tube, beaker 2 is stirred by a magnetic stirrer, and beaker 3 is left untreated. Add 2 drops of methyl orange to each of the three beakers, and observe the mixing of methyl orange and water. Under the condition of aeration rate of 25ml / min, it takes 1-2 seconds for the water in beaker 1 to completely mix with methyl orange. ; Under the condition of a stirring rate of 500r / min, the time required for complete mixing of water and methyl orange in beaker 2 is about 40s, while that of beaker 3 takes 1h. It can be seen that aeration can achieve rapid mixing of solutions.

specific Embodiment 2

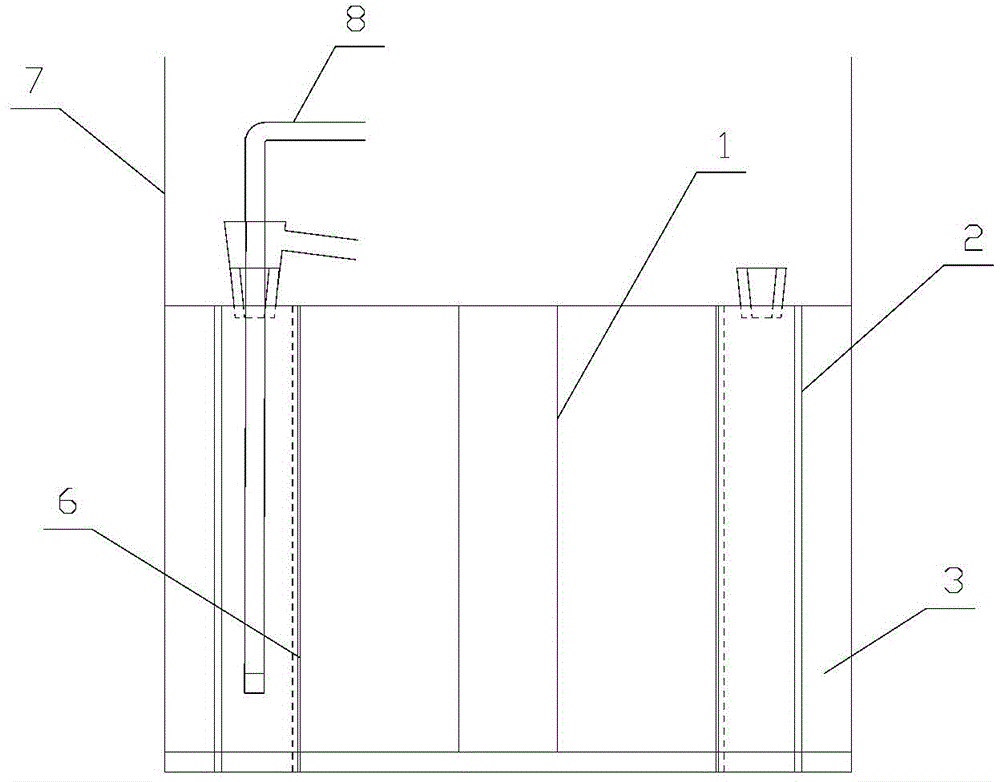

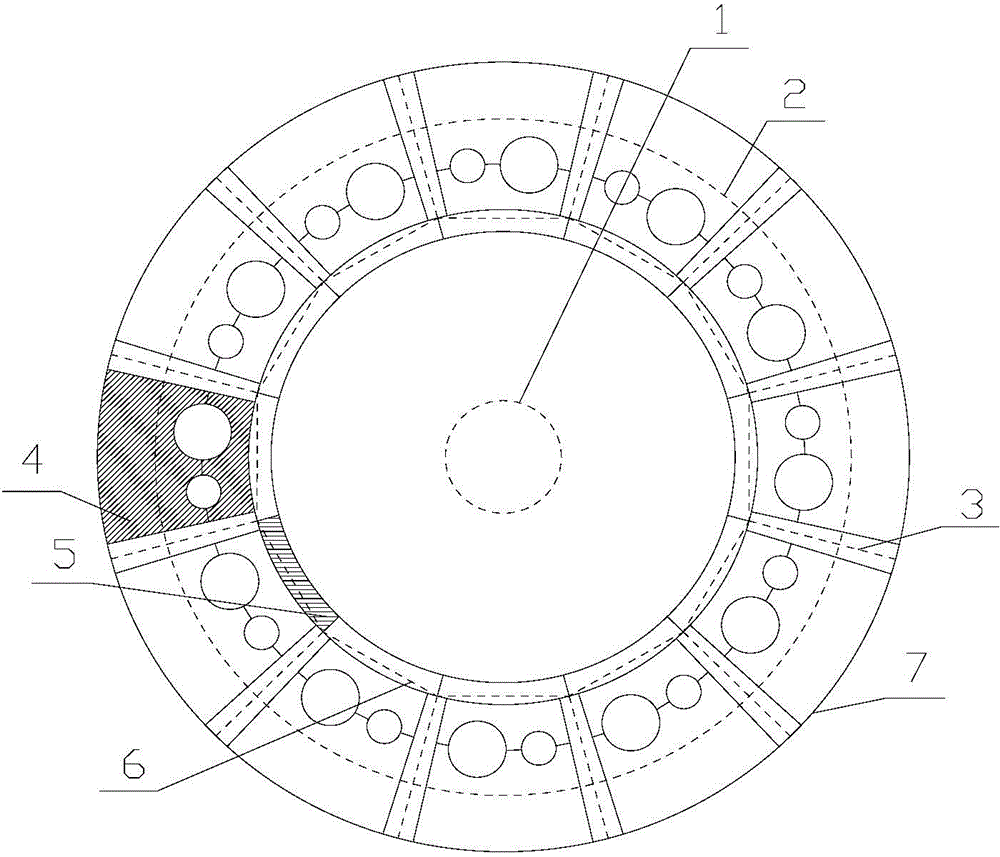

[0039] see Figure 1 to Figure 6 , the connection module, that is, the heat exchange connector, in which the cylindrical aluminum block is 310mm high, the bottom surface diameter is 100mm, the outer diameter and inner diameter of the copper air pipe and the copper temperature control pipeline are 3mm and 1mm respectively, and the number of turns of the copper air pipe is 49 turns, copper temperature control pipeline 50 turns. The water outlet of the constant temperature circulating water bath of the temperature control module is connected with the temperature control pipeline water inlet 94 of the heat exchange connector, and the temperature control pipeline water outlet 95 of the heat exchange connector is connected with the water inlet of the constant temperature circulation water bath of the temperature control module. At the same time, the air storage bottle of the aeration module is connected to the air inlet 96 of the heat exchange connector by plastic connecting pipelin...

specific Embodiment 3

[0040] Experimental condition and embodiment two are basically the same, and difference is: in three sample cups, add 200mL respectively, the trichlorophenol solution of 1mmol / L, use 2 sets of heat exchange connectors, its copper ventilation tube is respectively connected with nitrogen, nitrogen, The oxygen storage cylinders are connected, and nitrogen and oxygen are fed into the three sample cups respectively, and the last one is a blank control without any gas. The xenon lamp power of the photochemical reaction module device is 1000W, and samples are taken from the sampling port 24 at five time points of 0h, 4h, 8h, 12h, and 16h during the illumination process. Finally, the degradation rate constant of trichlorophenol was measured: the nitrogen gas was 0.05h -1 , oxygen is 0.09h -1 , the blank is 0.06h -1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com