Method for evaporation separation of liquid state mixture based on porous composite

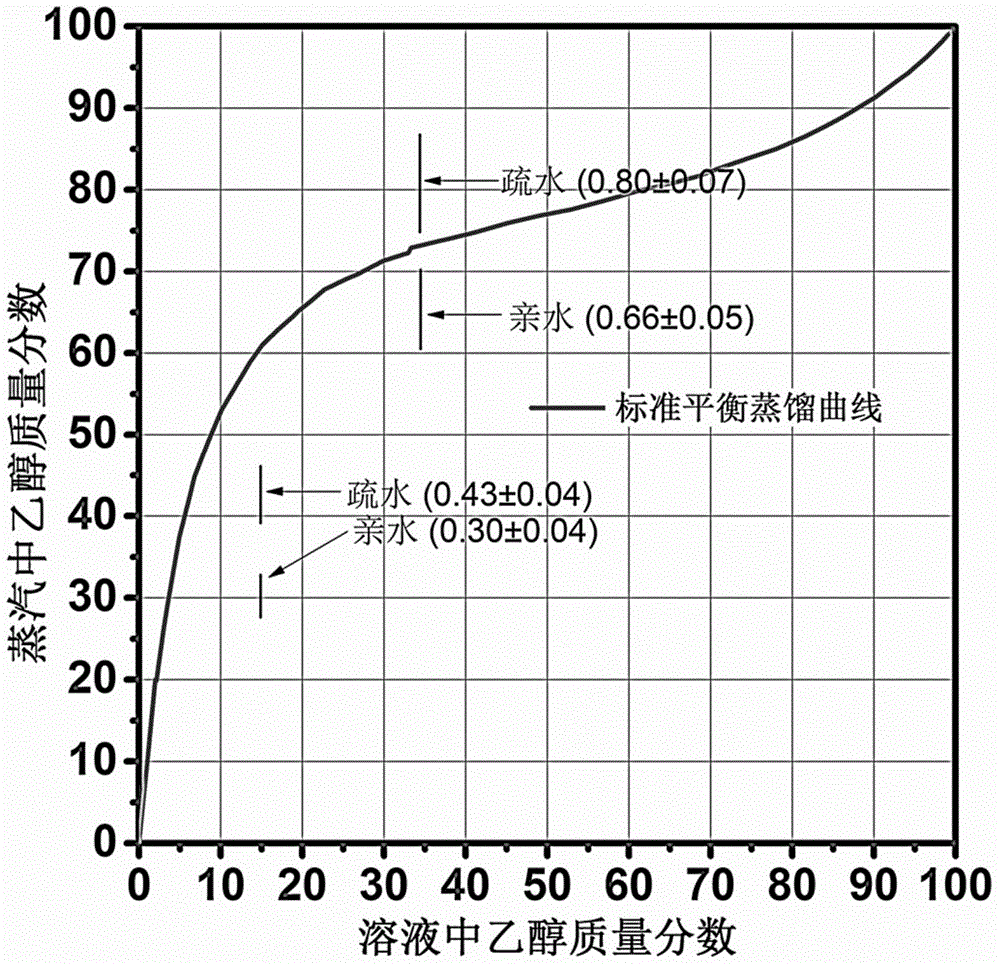

A porous composite material and separation method technology, applied in the application field of composite materials, can solve the problems of inability to overcome the separation of solution azeotropes, inability to control solution evaporation, and low energy utilization, and achieve mature and improved preparation and surface treatment technologies. The effect of photothermal conversion efficiency and improving utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

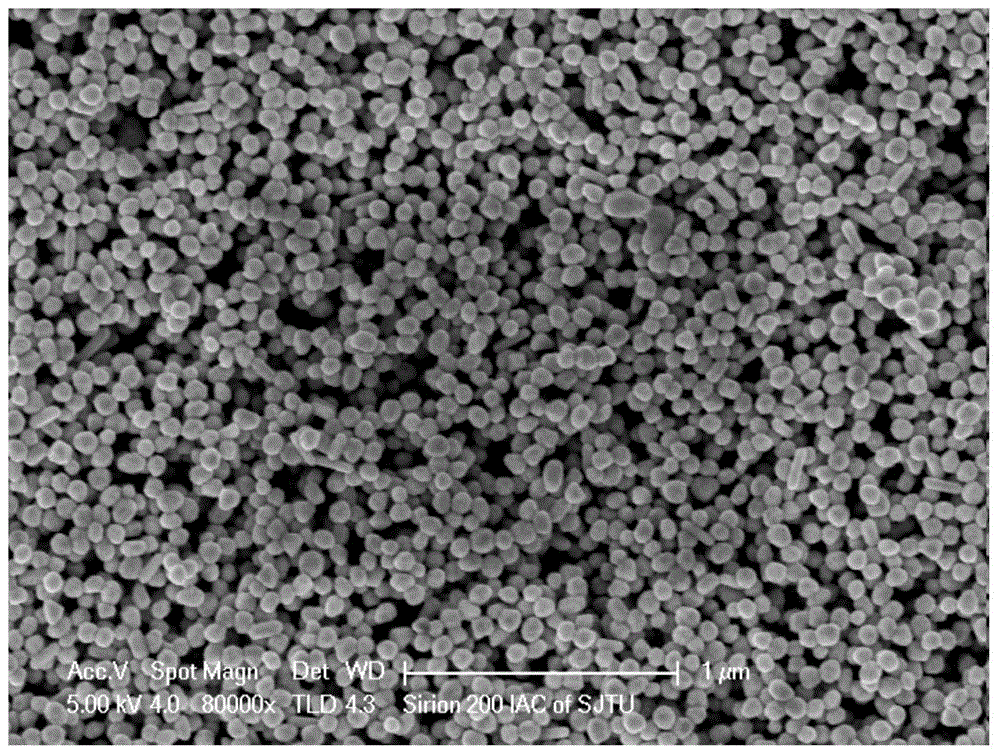

[0028] (1) Preparation of gold nanoparticles

[0029] A certain concentration of chloroauric acid (HAuCl 4 ) solution is added to boiling deionized water in a certain proportion, and immediately after stirring evenly, a certain concentration of trisodium citrate solution is added in proportion, then after stirring for 20 minutes under heating conditions, the heat source is removed, and stirring is continued for 15 minutes. Gold nanoparticles with a diameter of 10 nm were obtained. The obtained solution is used as a seed for growth of gold particles, the seed solution is diluted and a certain proportion of hydroxylamine hydrochloride solution and chloroauric acid solution are added to make the particle size of the gold nanoparticles grow, and the growth steps are repeated to make the particle size of the gold particles from 10nm to 10nm. Gradually grow about 100nm. The obtained solutions were combined and allowed to stand for a period of time for the solution to settle the pa...

Embodiment 2

[0037] (1) Preparation of gold nanoparticles: same as in Example 1, but only 10 nm particles need to be prepared.

[0038] (2) Preparation of paper-based composite membrane: use the particle solution obtained in (1), dilute the original solution 3 times, take 30ml of the diluted solution in a beaker, and spread a dust-free paper under the beaker, and place it in an atmosphere with formic acid Stand in a desiccator. After about 12 hours, the clear liquid below the liquid surface was removed, so that the surface self-assembled particle film was deposited on the dust-free paper; then the composite film was taken out and dried.

[0039] (3) The modification of the paper-based composite membrane is the same as in Example 1.

[0040] (4) The evaporation conditions of the paper-based composite film are the same as those in Example 1, only the evaporation efficiency is slightly different.

Embodiment 3

[0042] The composite membrane was modified with dodecanethiol instead; the other modification methods were the same as in Example 1, and the evaporation process was the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com