Novel technique for preparing high-purity montmorillonite by deeply purifying bentonite

A technology of bentonite and montmorillonite, which is applied in the field of separation and purification of montmorillonite, which can solve the problems of variable composition, fine grains, and difficulty in the purification of calcium-based montmorillonite, and achieve the effect of reducing agglomeration and mild chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] Put bentonite raw ore I (grade 65%) in an oven, fully dry at 60° C. for at least 8 hours, remove free water, make montmorillonite difficult to agglomerate, and obtain bentonite to be ground.

[0069] The bentonite to be ground is crushed and ground for 60 minutes, and the dispersant sodium hexametaphosphate is added to the water suspension of bentonite ore after grinding, wherein the mass ratio of montmorillonite and water in the water suspension is 1:12, and hexametaphosphate The amount of sodium is 1.0% of the mass of bentonite:

[0070] The dispersed bentonite I suspension was magnetically stirred for 20 hours and ultrasonically treated for 30 minutes, then centrifuged at 700r / min at a low speed to remove precipitated impurities, and then centrifuged at a high speed of 10000r / min to collect the precipitate to obtain purified montmorillonite.

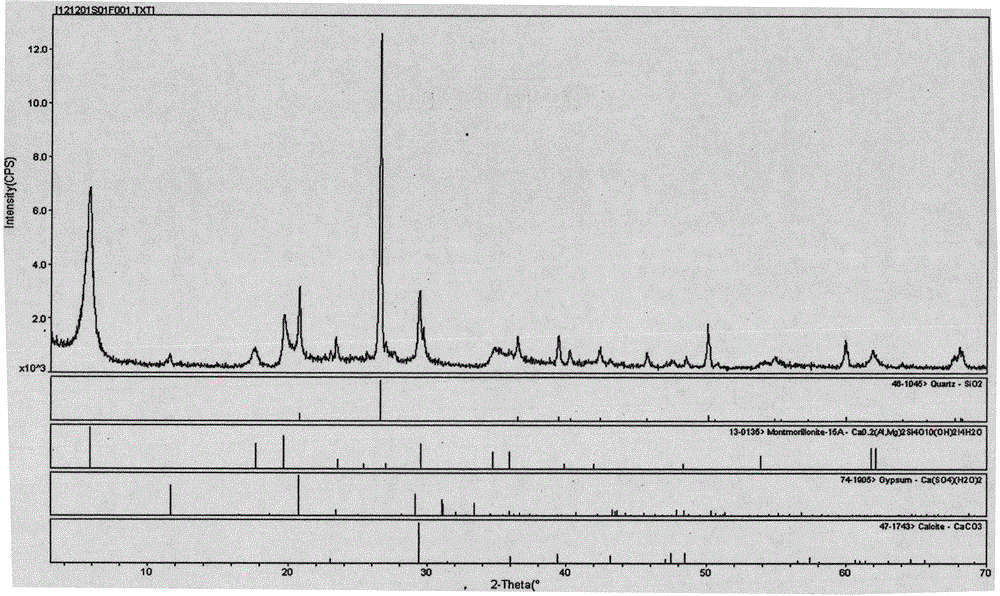

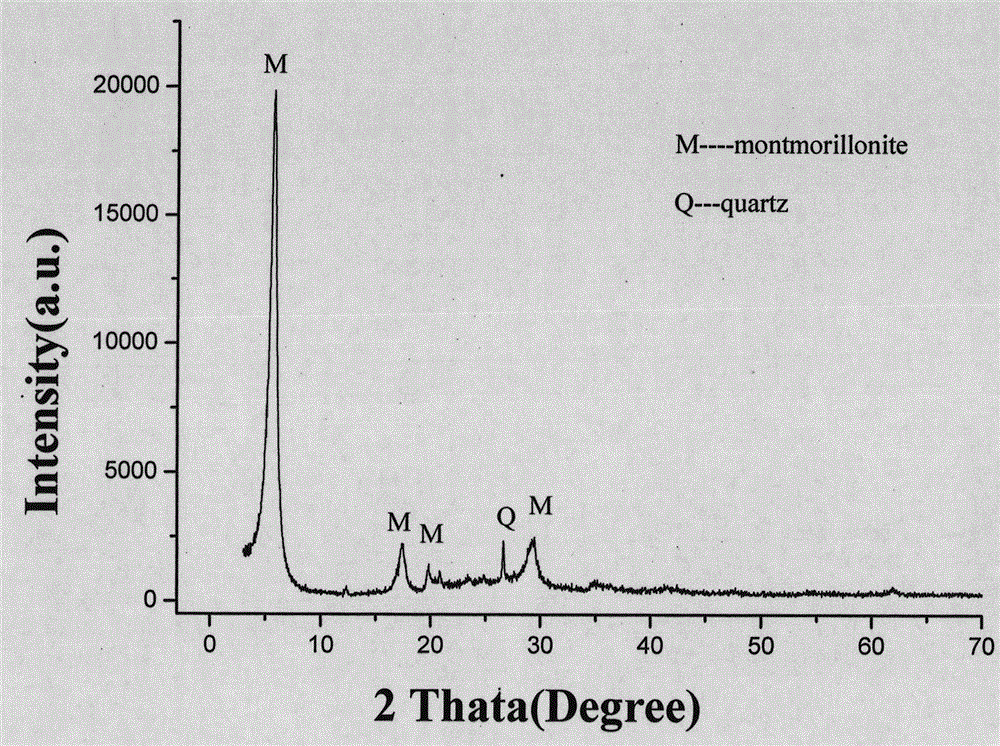

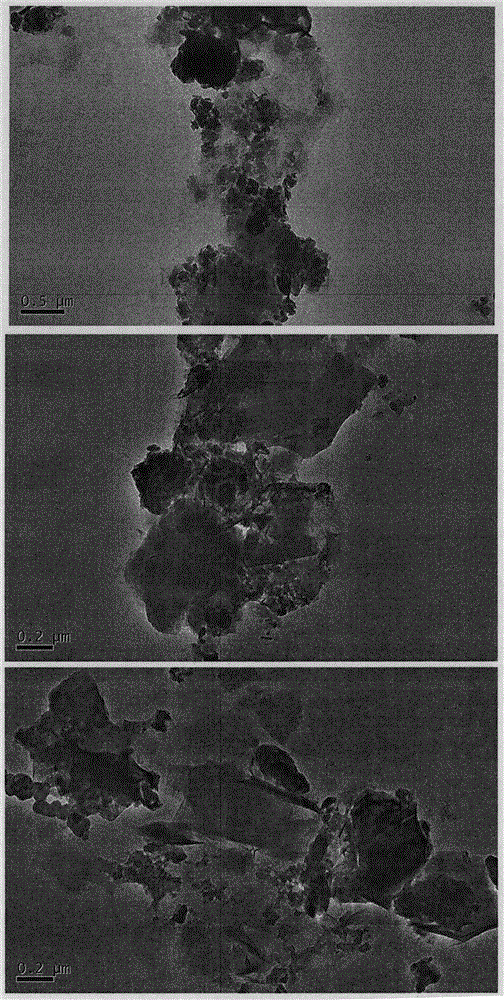

[0071] Wherein, the X-ray diffraction pattern of bentonite raw ore I is as follows figure 1 Shown,, the X-ray diffraction pa...

Embodiment 2

[0093] Put the bentonite raw ore I in an oven, fully dry at 60°C for at least 8 hours, remove free water, make the montmorillonite difficult to agglomerate, and obtain the bentonite to be ground.

[0094] The bentonite to be ground is crushed and ground for 30 minutes, and the dispersant sodium hexametaphosphate is added to the water suspension of bentonite ore after grinding, wherein the mass ratio of montmorillonite and water in the water suspension is 1:12, and the amount of dispersant 1.0% of the mass of bentonite;

[0095] The dispersed bentonite I suspension was magnetically stirred for 20 hours and ultrasonically treated for 30 minutes, then centrifuged at 700r / min at a low speed to remove precipitated impurities, and then centrifuged at a high speed of 10000r / min to collect the precipitate to obtain purified montmorillonite.

[0096] The X-ray diffraction pattern of gained high-purity montmorillonite powder product and figure 2 Shown similar, its purity was 93.7%, an...

Embodiment 3

[0098] Put the bentonite raw ore I in an oven, fully dry at 60°C for at least 8 hours, remove free water, make the montmorillonite difficult to agglomerate, and obtain the bentonite to be ground.

[0099] The bentonite to be ground is crushed and ground for 45 minutes, and the dispersant sodium hexametaphosphate is added to the water suspension of bentonite raw ore after grinding, wherein the mass ratio of montmorillonite and water in the water suspension is 1:12, and the amount of dispersant 1.0% of the mass of bentonite;

[0100] The dispersed bentonite suspension was magnetically stirred for 20 hours and ultrasonically treated for 30 minutes, then centrifuged at a low speed of 700r / min to remove precipitated impurities, and then centrifuged at a high speed of 10000r / min to collect the precipitate to obtain purified montmorillonite.

[0101] The X-ray diffraction pattern of gained high-purity montmorillonite powder product and figure 2 Shown similar, its purity was 94.7%, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com