Clenbuterol hydrochloride molecularly imprinted polymer and preparation method thereof

A clenbuterol hydrochloride and molecularly imprinted technology, which is applied in the field of clenbuterol hydrochloride molecularly imprinted polymer and its preparation, can solve the problems of blurred detection line color, invisible quality control line and high missed detection rate, To achieve the effect of good blotting effect, simple and fast synthesis, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A preparation method of clenbuterol hydrochloride molecularly imprinted polymer, comprising the following steps:

[0026] 1. The preparation concentration is 3×10 -4 The clenbuterol hydrochloride aqueous solution of mol / L;

[0027] 2. Add 5 μL of α-methacrylic acid to 20 mL at a concentration of 3 x 10 -4 mol / L clenbuterol hydrochloride aqueous solution, ultrasonic treatment for 10 minutes, then add 0.0028g N, N-methylenebisacrylamide, continue ultrasonic treatment for 20 minutes, stand overnight, to get the mixed solution (the Clenbuterol hydrochloride Tero, α-methacrylic acid, N, the molar ratio of N-methylenebisacrylamide addition is 9.78:1:3.03);

[0028] 3. Slowly add 100 μL of ammonium persulfate solution with a concentration of 0.5 mol / L to the mixed solution obtained in step 2, and ultrasonically treat it for 15 minutes to initiate a polymerization reaction to obtain a clenbuterol hydrochloride molecularly imprinted polymer.

Embodiment 2

[0030] A preparation method of clenbuterol hydrochloride molecularly imprinted polymer, comprising the following steps:

[0031] 1. The preparation concentration is 3×10 -5 The clenbuterol hydrochloride aqueous solution of mol / L;

[0032] 2. Add 3 μL of α-methacrylic acid to 10 mL to a concentration of 3 x 10 -5 mol / L clenbuterol hydrochloride aqueous solution, sonicated for 5 minutes, then added 0.0014g N,N-methylenebisacrylamide, continued sonicated for 10 minutes, left standing overnight to obtain a mixed solution (the Clenbuterol hydrochloride Tero, α-methacrylic acid, N, the molar ratio of N-methylenebisacrylamide addition is 117:1:30);

[0033] 3. Slowly add 80 μL of ammonium persulfate solution with a concentration of 0.5 mol / L to the mixed solution obtained in step 2, and ultrasonically treat for 10 minutes to initiate a polymerization reaction to obtain a clenbuterol hydrochloride molecularly imprinted polymer.

Embodiment 3

[0035] A preparation method of clenbuterol hydrochloride molecularly imprinted polymer, comprising the following steps:

[0036] 1. The preparation concentration is 3×10 -3 The clenbuterol hydrochloride aqueous solution of mol / L;

[0037] 2. Add 7 μL of α-methacrylic acid to 30 mL at a concentration of 3 x 10 -3 mol / L clenbuterol hydrochloride aqueous solution, sonicated for 15 minutes, then added 0.0042g N, N-methylenebisacrylamide, continued sonicated for 30 minutes, left standing overnight, to obtain a mixed solution (the Clenbuterol hydrochloride Tero, α-methacrylic acid, N, the molar ratio of N-methylenebisacrylamide addition is 274:300:90);

[0038] 3. Slowly add 120 μL of ammonium persulfate solution with a concentration of 0.5 mol / L to the mixed solution obtained in step 2, and ultrasonically treat it for 20 minutes to initiate a polymerization reaction to obtain a clenbuterol hydrochloride molecularly imprinted polymer.

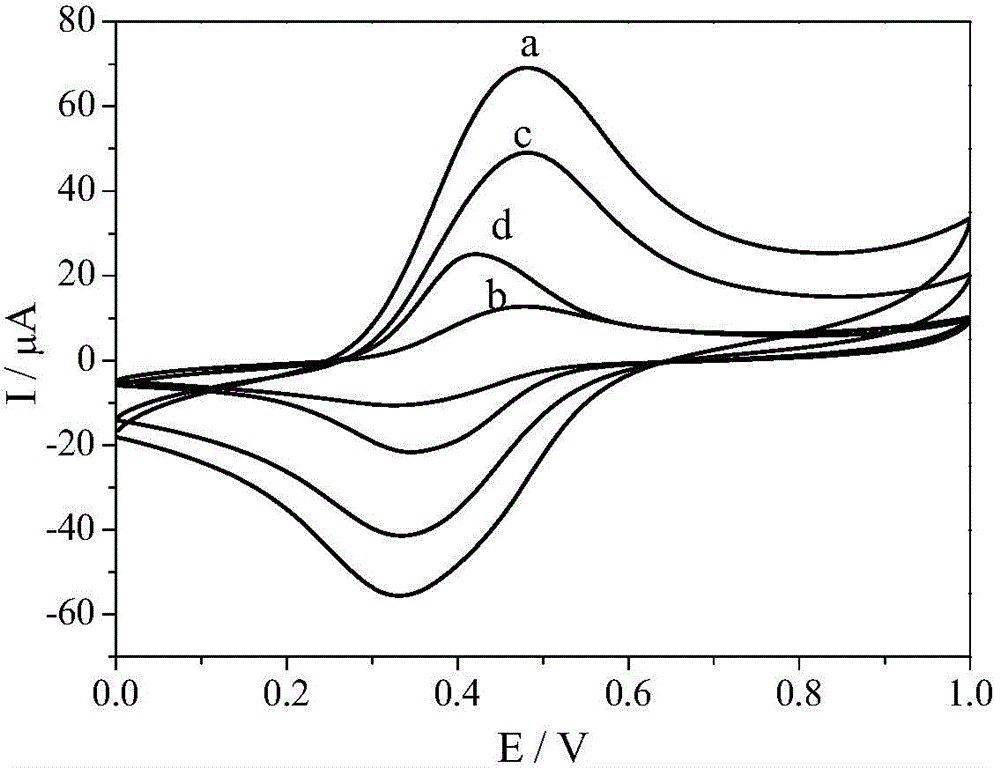

[0039] 2. Analysis of Clenbuterol Hydrochlori...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com