Method for recycling rare earth compound by using waste rare earth polishing powder

A rare earth polishing powder and rare earth compound technology, applied in the direction of improving process efficiency, can solve the problems of difficult industrial production, inadvisable large-scale production, and inapplicability, so as to achieve low equipment manufacturing costs and improve the comprehensive utilization of secondary resources The level of optimization and the effect of optimizing the level of comprehensive utilization of secondary resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

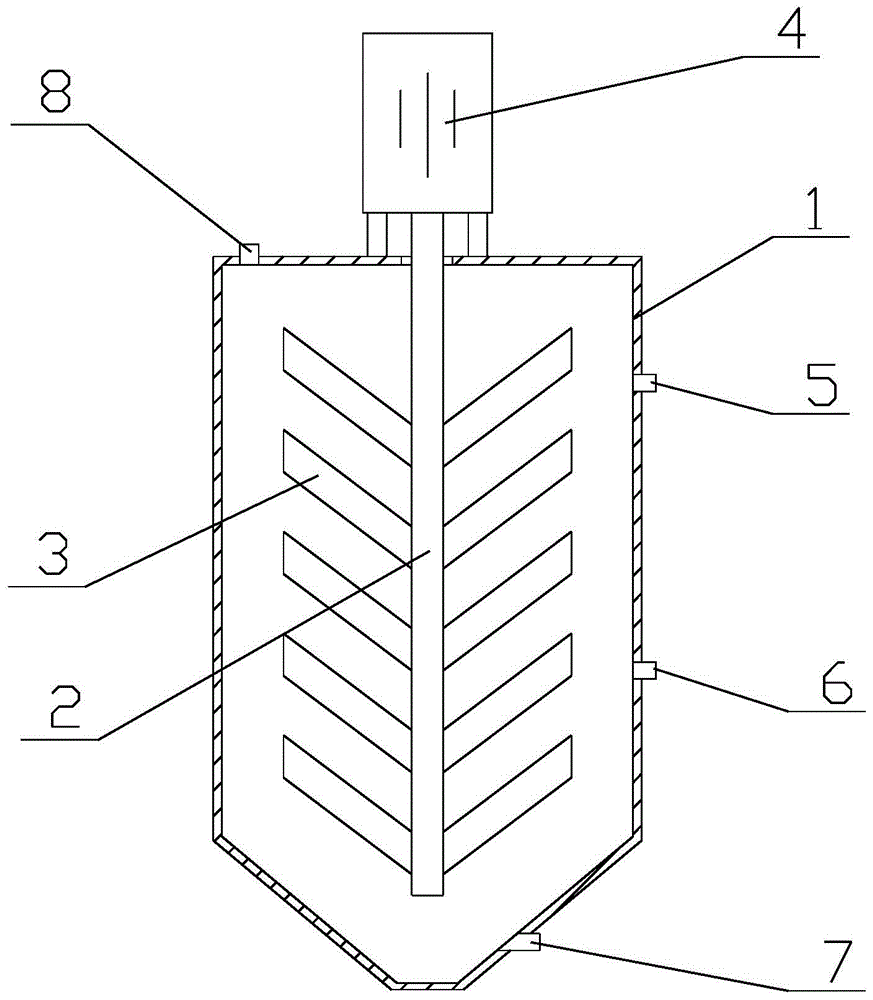

Image

Examples

Embodiment 1

[0029] Embodiment 1: A method for recycling rare earth compounds using waste rare earth polishing powder, which includes the following steps: (1) enriching waste rare earth polishing powder to prepare enriched materials for rare earth elements;

[0030] a. Preparation of slurry: add the waste rare earth polishing powder mixture with total amount of rare earth TREO=35wt%, add water and soak for 5 minutes to make slurry, the slurry mass concentration is 20%, then add industrial hydrochloric acid, industrial hydrochloric acid to the slurry If the concentration is greater than 36wt%, the pH value of the slurry is adjusted to 3, and the pH value is well controlled. If the acidity is too strong, the dissolution rate is too high, which will cause the material to be mushy and difficult to filter and precipitate. Then the slurry is stirred in the mixing agitator for 20 minutes and then enters the spiral classifier by the conduit. The rotating speed of the mixing agitator is 30 rpm; It ...

Embodiment 2

[0041] Embodiment 2: A method for recycling rare earth compounds using waste rare earth polishing powder, which includes the following steps: (1) enriching waste rare earth polishing powder to prepare enriched materials for rare earth elements;

[0042] a. Preparation of slurry: add the waste rare earth polishing powder mixture with the total amount of rare earth TREO=35wt%, add water and soak for 10 minutes to make slurry, the slurry mass concentration is 20%, then add industrial hydrochloric acid and industrial hydrochloric acid to the slurry If the concentration is greater than 36wt%, the pH value of the slurry is adjusted to 4, and the pH value is well controlled. The acidity is too strong and the dissolution rate is too high, which will cause the material to be mushy and difficult to filter and precipitate. Then the slurry is stirred in the mixing agitator for 25 minutes and then enters the spiral classifier by the conduit, and the rotating speed of the mixing agitator is ...

Embodiment 3

[0053] Embodiment 3: A method for recycling rare earth compounds by using waste rare earth polishing powder, which includes the following steps: (1) enriching waste rare earth polishing powder to prepare enriched materials for rare earth elements;

[0054] a. Preparation of slurry: add the waste rare earth polishing powder mixture with the total amount of rare earth TREO=35wt%, add water and soak for 8 minutes to make slurry, the slurry mass concentration is 20%, then add industrial hydrochloric acid, industrial hydrochloric acid to the slurry If the concentration is greater than 36wt%, the pH value of the slurry is adjusted to 3, and the pH value is well controlled. If the acidity is too strong, the dissolution rate is too high, which will cause the material to be mushy and difficult to filter and precipitate. Then the slurry is stirred in the mixing agitator for 22 minutes and then enters the spiral classifier by the conduit, and the rotating speed of the mixing agitator is 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com