Intelligent high temperature heat pump drying system with damp-heat recovery

A high-temperature heat pump and drying system technology, which is applied in drying, dryers, and drying solid materials, can solve the problems of unusable waste heat from dehumidification, poor temperature and humidity adjustment, and high operating costs, and achieve a broad market application prospect. The effect of system design optimization and huge market potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

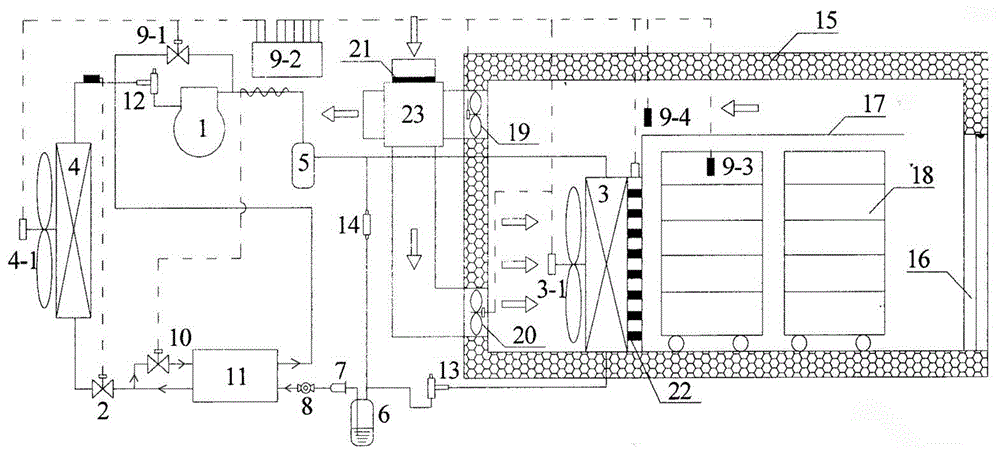

[0019] Such as figure 1 As shown, the present invention provides an intelligent high-temperature heat pump drying system with damp heat recovery, which includes a high-temperature heat pump subsystem, a damp heat recovery subsystem, a temperature and humidity control and adjustment subsystem, and a drying house system. The high-temperature heat pump subsystem described therein includes a compressor 1, a throttling device 2, an air-cooled condenser 3, an air-cooled evaporator 4, an oil separator 5, a liquid reservoir 6, a dry filter 7, a sight glass 8, Energy regulating valve 9-1, liquid injection valve 10, subcooler 11, suction pressure regulating valve 12, high pressure regulating valve 13, differential regulating valve 14 and connecting pipes; the specific connection relationship is the exhaust port of compressor 1 It is divided into two interfaces, one of which is connected to the inlet of the suction pressure regulating valve 12 through the energy regulating valve 9-1, and...

Embodiment 2

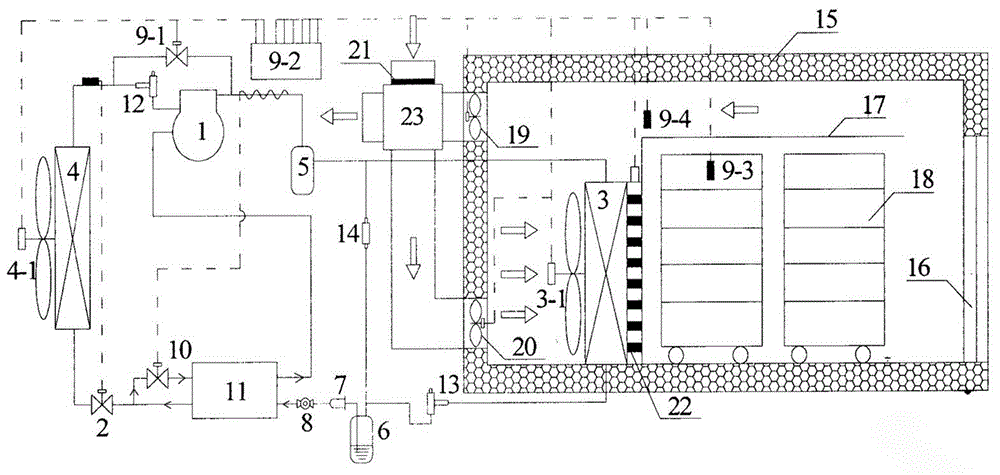

[0021] Such as figure 2 As shown, the difference between this embodiment and Embodiment 1 is that the subcooler 11 is no longer connected to the inlet of the suction pressure regulating valve 12 , but is connected to the medium-pressure air supplement chamber of the compressor.

[0022] The compressor 1 of the present invention is any one of a fixed-frequency compressor, a step-by-step compressor, a variable-frequency compressor, and an air-supplementing enthalpy-increasing compressor; the air-cooled condenser 3 and the air-cooled evaporator 4 It is any structural form of tube-fin type, stacked type, and parallel flow heat exchanger; the air-cooled condenser fan 3-1, the air-cooled evaporator fan 4-1, the moisture-exhausting heat-exhausting fan 19, The fresh air fan 20 is any one of a variable frequency fan, a fixed frequency fan, and a shifting fan; the throttling device 2 is any structural form of a thermal expansion valve, a capillary expansion valve or an electronic expansi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com