Forming method of semiconductor structure

A semiconductor and gate structure technology, applied in the field of semiconductor structure formation, can solve problems such as complex process steps, affecting memory reliability, and deterioration of dielectric layer isolation performance, and achieve smooth inner walls, improved inner wall contours, and increased top width Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

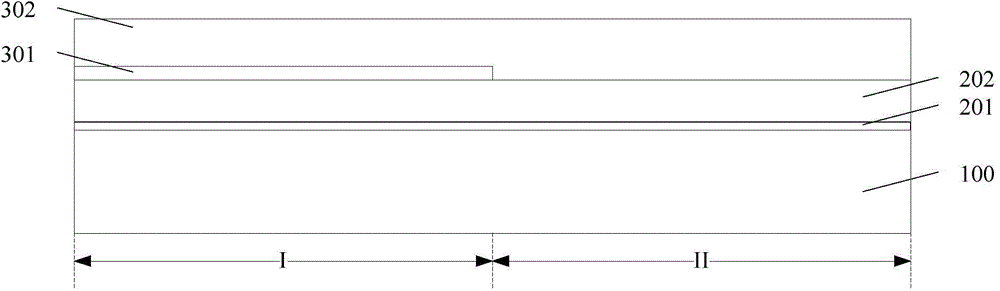

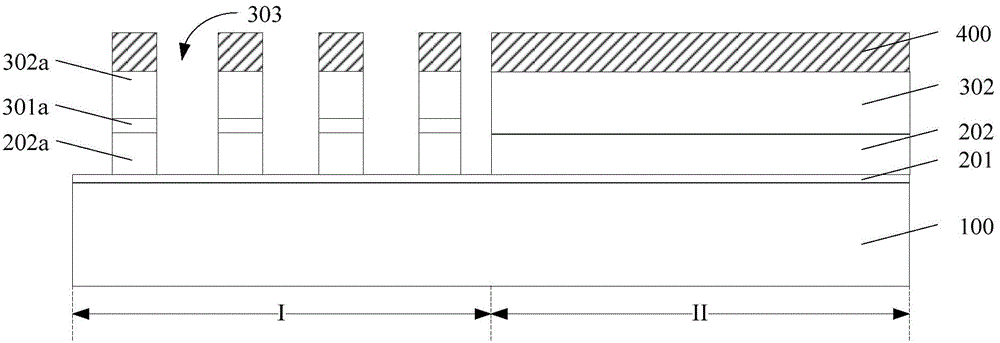

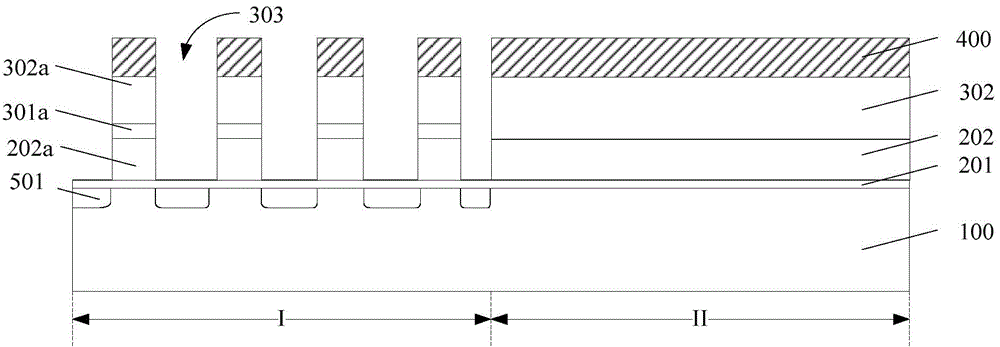

[0029] As mentioned in the background art, due to the small distance between adjacent storage units, it is difficult to fill the space with dielectric materials, and defects such as voids are easily formed, which affects the reliability of the memory.

[0030] In the process of forming the sidewall of the transistor of the peripheral circuit, a chemical vapor deposition process is used. After the sidewall material layer is formed on the semiconductor substrate, the sidewall material layer is etched without a mask to form the side wall. But because the space between the storage units is small, in the process of forming the sidewall material layer, the sidewall material layer will fill up the grooves between the storage units, but due to the space between the storage units Smaller, resulting in a higher aspect ratio of the groove, resulting in more defects such as voids in the side wall material layer filled in the groove. Subsequently, after forming the side walls of the trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com