Preparation method of lithium titanate cathode material with high tap density

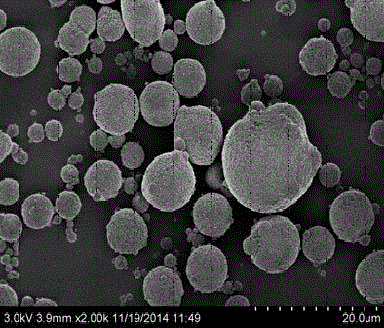

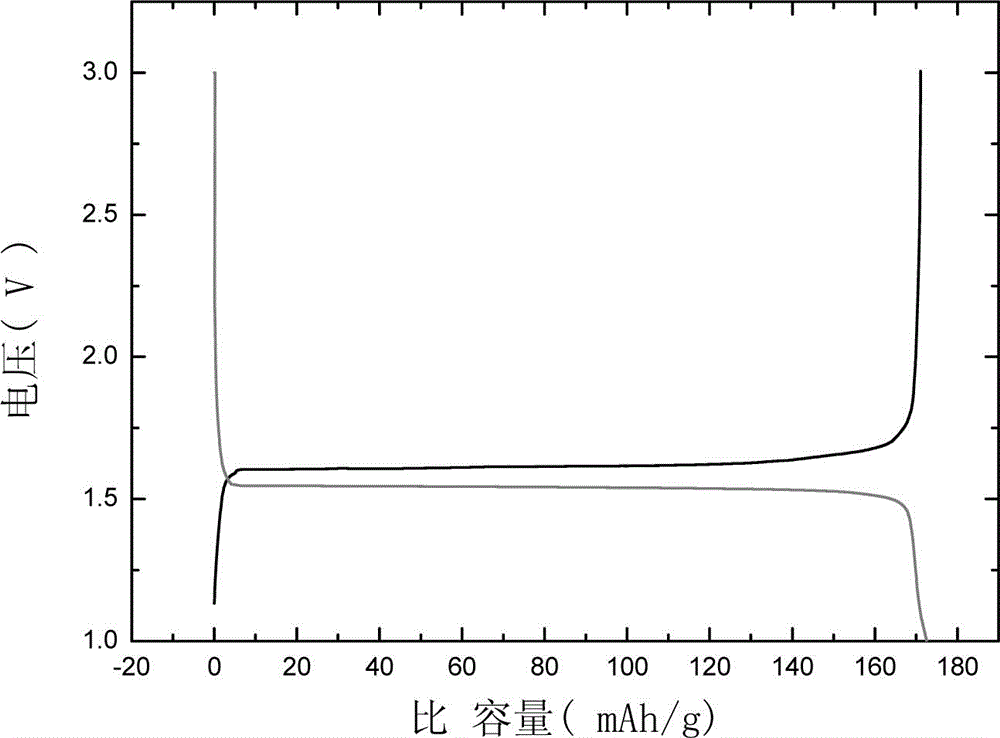

A density lithium titanate and negative electrode material technology, applied in the direction of negative electrodes, battery electrodes, active material electrodes, etc., can solve the problems of low tap density, affecting battery quality, and low specific energy of batteries, achieving high energy density and increasing The effect of high contact area and specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A preparation method of a high tap density lithium titanate negative electrode material, comprising the steps of:

[0034] (1) Mixing of raw materials: Add 200L of deionized water into the mixing tank, mix according to the molar ratio of Li:Ti=0.81:1, weigh 30kg LiOH·H 2 O and 80kg TiO 2 Disperse in deionized water and stir for more than 2 hours to make it fully mixed.

[0035] (2) Spray drying: The uniformly stirred slurry is spray-dried to obtain a uniformly mixed powder.

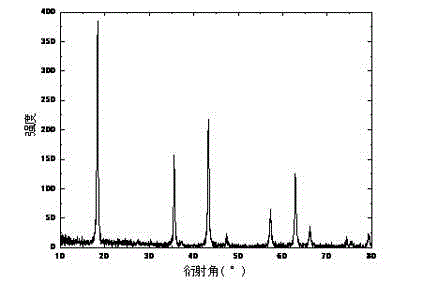

[0036] (3) High-temperature calcination: heat up the roller sintering furnace according to the heating curve, load the spray-dried powder into the SiC sagger, and put it into the sintering furnace for calcination under the air atmosphere. The temperature in the holding zone is 850°C. The holding time is 4 hours, and then cooled naturally to obtain lithium titanate powder with high purity.

[0037] (4) Wet ball milling: add 0.2-1.0mm zirconia beads into the ball mill as the grinding medium, add l...

Embodiment 2

[0043] A preparation method of a high tap density lithium titanate negative electrode material, comprising the steps of:

[0044] (1) Mixing of raw materials: Add 250L of deionized water into the mixing tank, and weigh 26kg of Li according to the molar ratio of Li:Ti=0.82:1 2 CO 3 and 80kg TiO 2 Disperse in deionized water and stir for more than 2 hours to make it fully mixed.

[0045] (2) Spray drying: The uniformly stirred slurry is spray-dried to obtain a uniformly mixed powder.

[0046] (3) High-temperature calcination: heat up the roller sintering furnace according to the heating curve, load the spray-dried powder into the SiC sagger, and put it into the sintering furnace for calcination under the air atmosphere. The temperature in the holding zone is 850°C. The holding time is 4 hours, and then cooled naturally to obtain lithium titanate powder with high purity.

[0047] (4) Wet ball milling: add 0.2-1.0mm zirconia beads into the ball mill as the grinding medium, ad...

Embodiment 3

[0053] A preparation method of a high tap density lithium titanate negative electrode material, comprising the steps of:

[0054] (1) Add 200L of deionized water into the mixing tank, and weigh 24.5kg of LiNO according to the molar ratio of Li:Ti=0.82:1 3 and 80kg TiO 2 Disperse in deionized water and stir for more than 2 hours to make it fully mixed.

[0055] (2) Spray drying: The uniformly stirred slurry is spray-dried to obtain a uniformly mixed powder.

[0056] (3) High-temperature calcination: heat up the roller sintering furnace according to the heating curve, load the spray-dried powder into the SiC sagger, and put it into the sintering furnace for calcination under the air atmosphere. The temperature in the holding zone is 850°C. The holding time is 4 hours, and then cooled naturally to obtain lithium titanate powder with high purity.

[0057] (4) Wet ball milling: add 0.2-1.0mm zirconia beads into the ball mill as the grinding medium, add lithium titanate powder i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com