Solid electrolyte for lithium ion battery, preparation method for solid electrolyte, and lithium ion battery

A solid electrolyte, lithium-ion battery technology, applied in the manufacture of solid electrolyte, non-aqueous electrolyte batteries, electrolyte batteries, etc., can solve the problems of high grain boundary resistance and poor compatibility, improve performance and reduce inter-grain resistance. , Optimize the effect of interface contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] The present invention also provides the preparation method of described lithium-ion battery solid electrolyte, and this method comprises the following steps:

[0023] S1. Preparation of Li 1+x m x Zr 2-x (PO 4 ) 3 , the ZrO 2 , M 2 o 3 , NH 4 h 2 PO 4 It is mixed with lithium source compound by ball milling and then calcined for the first time. After cooling, Li 1+x m x Zr 2-x (PO 4 ) 3 Powder;

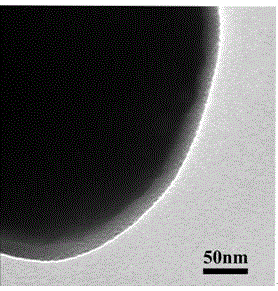

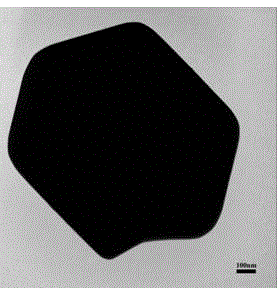

[0024] S2, the raw material of shell material is dissolved in water, then adds to Li 1+x m x Zr 2-x (PO 4 ) 3 In the powder, stir and adjust the pH of the system to 8-11, so that the shell material forms a gel and coats the Li 1+x m x Zr 2-x (PO 4 ) 3 On the powder particles, after drying, a composite material with a core-shell structure is obtained;

[0025] S3. Compressing the composite material obtained in step S2, then performing a second calcination, and obtaining a lithium-ion electrolyte solid electrolyte after cooling.

[0026] According to the...

Embodiment 1

[0037] (1) According to the core composition of the core-shell structure material is Li 1.1 Y 0.1 Zr 1.9 (PO 4 ) 3 The stoichiometric ratio, respectively weighed Li 2 CO 3 powder, Y 2 o 3 powder, ZrO 2 Powder and NH 4 h 2 PO 4 , ball milled and mixed evenly;

[0038] (2) Put the homogeneously mixed powder in step (1) into an alumina crucible, then place it in a muffle furnace for calcination at 800°C for 6 hours, and obtain Li 1.1 Y 0.1 Zr 1.9 (PO 4 ) 3 Powder;

[0039] (3) According to the shell composition Li 0.15 B 0.95 PO 4 Accounting for 2wt% of the total mass of the solid electrolyte, weigh the required LiOH, H 3 BO 3 and NH 4 h 2 PO 4 Dissolve in deionized water, add the corresponding mass of Li 1.1 Y 0.1 Zr 1.9 (PO 4 ) 3 powder, vigorously stir evenly, and adjust the pH value of the system to make Li 0.15 B 0.95 PO 4 Form a homogeneous gel coated on the Li 1.1 Y 0.1 Zr 1.9 (PO 4 ) 3 On the powder particles, the mixed powder is drie...

Embodiment 2

[0042] (1) According to the core composition of the core-shell structure material is Li 1.1 Al 0.1 Zr 1.9 (PO 4 ) 3 The stoichiometric ratio, respectively weighed Li 2 CO 3 Powder, Al 2 o 3 powder, ZrO 2 Powder and NH 4 h 2 PO 4 , ball milled and mixed evenly;

[0043] (2) The desired lithium ion solid electrolyte sheet A2 was obtained by the same treatment method as in steps (2) to (4) of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com