Water-based epoxy resin paint and preparation method thereof

A water-based epoxy resin and epoxy resin technology, applied in the direction of epoxy resin coatings, coatings, etc., can solve the problems of general impact resistance, high brittleness, unsatisfactory anti-corrosion performance, etc., and achieve good film-forming performance and mechanical mechanical properties. The effect of good performance and excellent storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Mix 20g of octylphenol polyoxyethylene ether with 100g of polyoxyethylene sorbitan monolaurate, heat up to 70°C, add 0.1g of sodium lauryl sulfate dropwise, and stir for 4 hours under nitrogen protection to prepare Get an emulsifier. Under a 6000r / min high shear machine, add 15g of emulsifier and 5g of propylene glycol methyl ether to 100g of epoxy resin E-51, mix well, and add 120mL of deionized water dropwise to the system while stirring at 70°C until The system changed from water-in-oil to oil-in-water, and then stirred and reacted for 2 hours to obtain a water-based epoxy resin emulsion.

[0052]Put 32.2g of triethylenetetramine in a 250mL round bottom flask, raise the temperature to 60°C, add 28g of epoxy resin solution dropwise under stirring (including 20g of epoxy resin E-51, 8g of diethylene glycol dimethyl ether), drop After the addition was completed, react at 65°C for 4h, then add 13g of n-butyl glycidyl ether dropwise to the system, and react at 80°C for 2...

Embodiment 2

[0057] Same as Example 1, but the amount of water-based epoxy resin curing agent is changed from 30g to 25g.

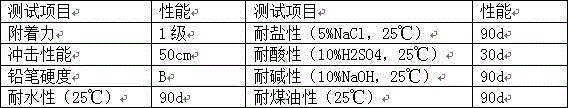

[0058] The properties of the coating are as follows:

[0059]

Embodiment 3

[0061] Same as Example 1, but the amount of water-based epoxy resin curing agent is changed from 30g to 20g.

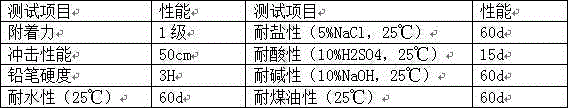

[0062] The properties of the coating are as follows:

[0063]

PUM

| Property | Measurement | Unit |

|---|---|---|

| adhesivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com