Garnet-structure multiphase fluorescent material and preparation method thereof

A fluorescent material, garnet technology, applied in the field of lighting units, can solve the problems of large particle size of fluorescent materials, poor luminous intensity, poor chemical stability and thermal stability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Example 1: Y 2.95 al 5.2 o 11.4 N 0.6 :0.05Ce, 0.025F 0.15Ag

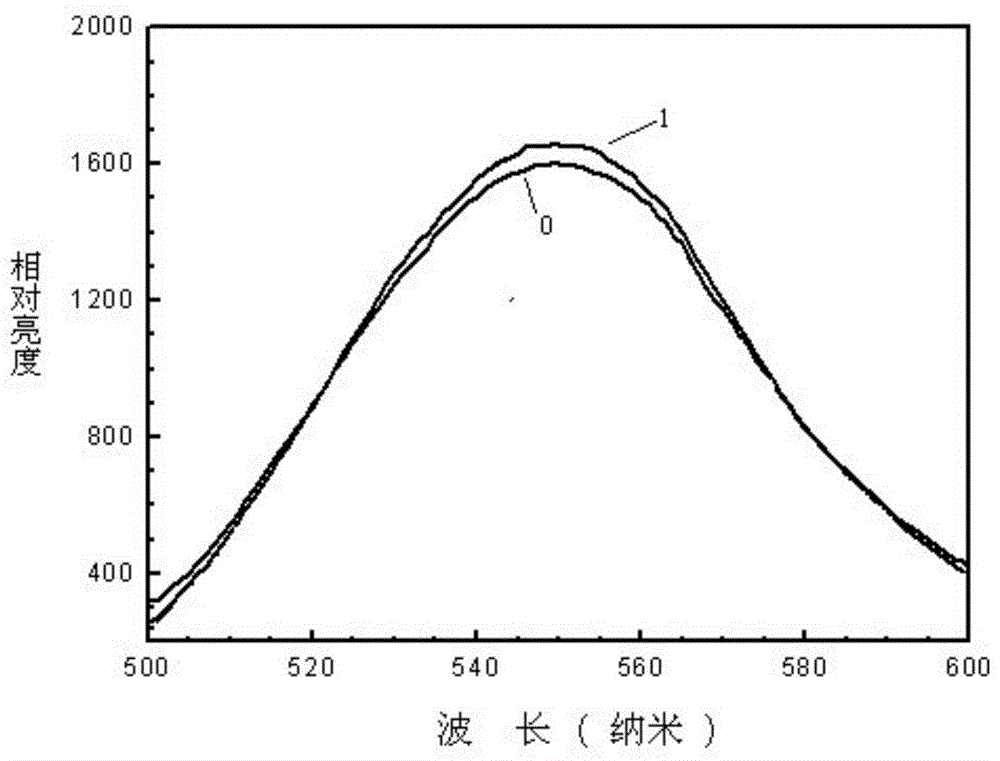

[0051] Weigh Y according to the molar ratio 2 o 3 333.07g, CeO 2 8.61g,Al 2 o 3 234.51g, AlN 24.59g, BaF 2 2.19g, mixed and ground, weighed 16.19g of Ag powder according to the molar ratio, remixed the two evenly, pre-fired the mixed raw materials at 1400-1500°C for 6 hours in an air atmosphere, and then heated them in a weak reducing atmosphere at 1500°C Sintering at lower temperature for 5 hours, the sintered body was cooled, crushed and ground to obtain the composite phosphor with garnet structure. figure 1 It is the emission spectrum of the composite phosphor obtained in Example 1, and its emission wavelength is at 550nm. Compared with the comparative example 1 of the simple phosphor with the same composition but not containing Ag particles, the luminous intensity of the composite phosphor improves about 5%.

Embodiment 2

[0054] Example 2: Y 2.95 al 4.7 Ga 0.5 o 11.4 N 0.6 :0.05Ce, 0.025F 0.15Ag

[0055] Weigh Y according to the molar ratio 2 o 3 333.07g, CeO 2 8.61g,Al 2 o 3 209.02g, AlN 24.59g, Ga 2 o 3 46.86g, BaF 2 2.19g, mixed and ground, weighed 16.19g of Ag powder according to the molar ratio, re-mixed the two evenly, and pre-fired the mixed raw materials at 1400-1500°C for 6 hours in an air atmosphere, then put them in a weak Heat preservation and sintering for 5 hours in a reducing atmosphere, and the sintered body is cooled and crushed and ground to obtain the complex-phase phosphor with the garnet structure.

Embodiment 3

[0056] Example 3: Lu 2.95 al 5.2 o 11.4 N 0.6 :0.05Ce, 0.025F 0.15Ag

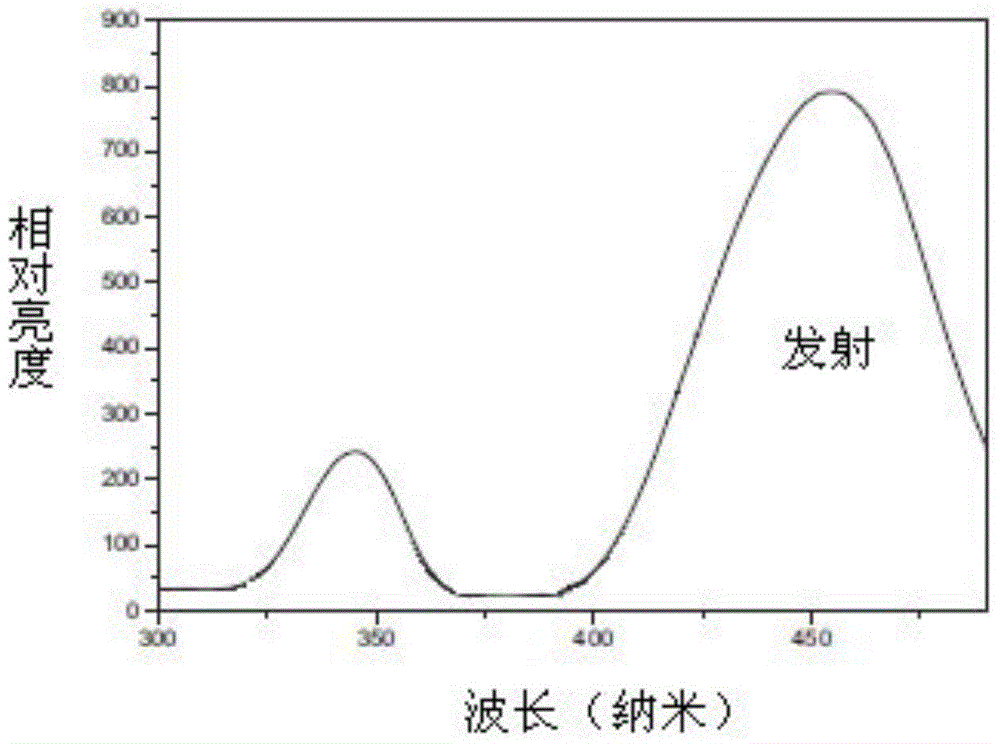

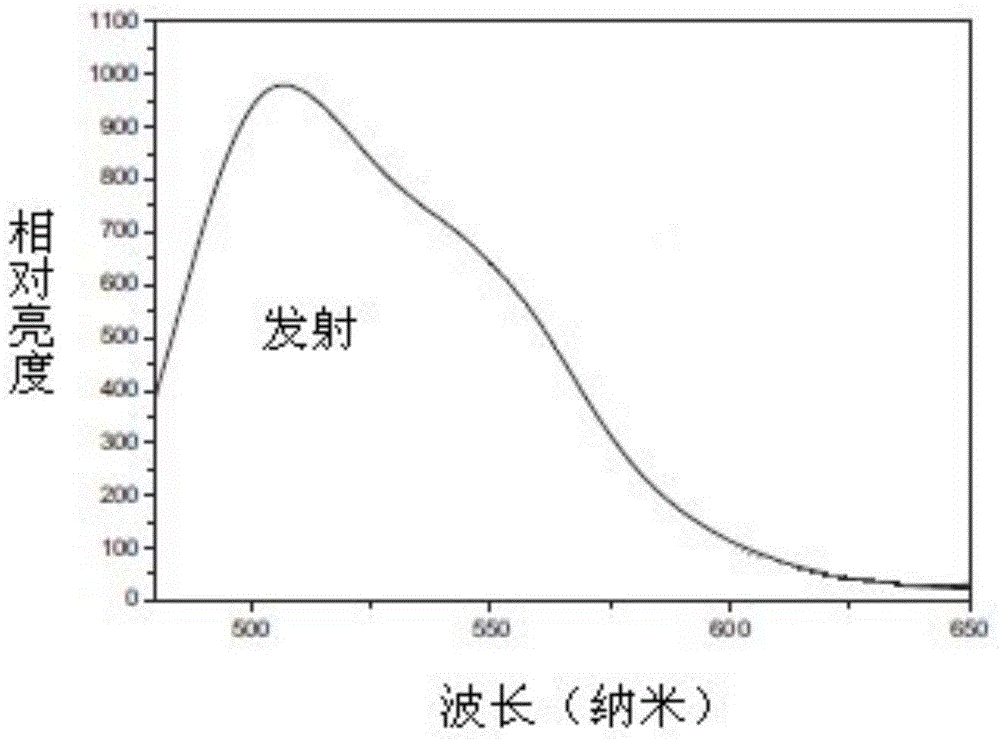

[0057] Weigh Lu according to the molar ratio 2 o 3 587.05g, CeO 2 8.61g,Al 2 o 3 234.51g, AlN 24.59g, BaF 2 2.19g, mixed and ground, weighed 16.19g of Ag powder according to the molar ratio, re-mixed the two evenly, and pre-fired the mixed raw materials at 1400-1500°C for 6 hours in an air atmosphere, then put them in a weak Heat preservation and sintering for 5 hours in a reducing atmosphere, and the sintered body is cooled and crushed and ground to obtain the complex-phase phosphor with the garnet structure. figure 2 It is the excitation spectrum of the composite phosphor obtained in Example 3, image 3 It is the emission spectrum of the composite phosphor obtained in Example 3, and its emission wavelength is at 527nm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com