System and method for producing raw material of needle coke by oil slurry

A needle coke raw material and oil slurry technology, which is applied in the petroleum industry, hydrocarbon oil treatment, and only multi-stage serial refining process treatment, etc., can solve the problem of limiting the source of raw material oil slurry, increasing production costs, and relatively low requirements for solid content indicators. Strict and other problems, to eliminate competitive adsorption, improve removal effect, and high separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

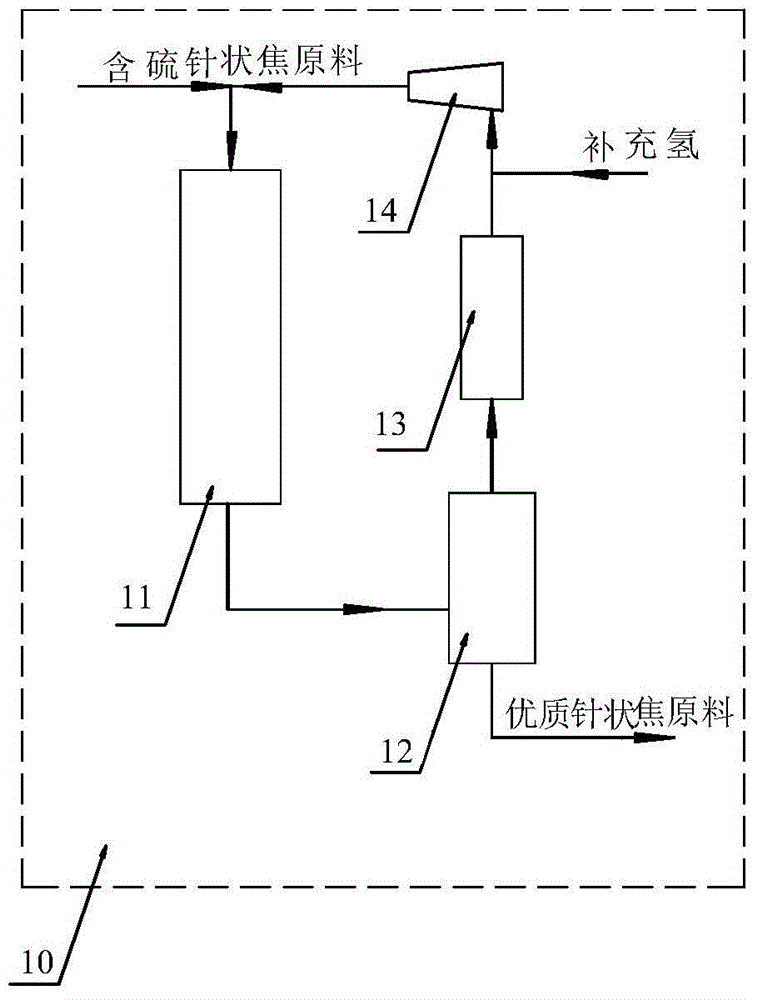

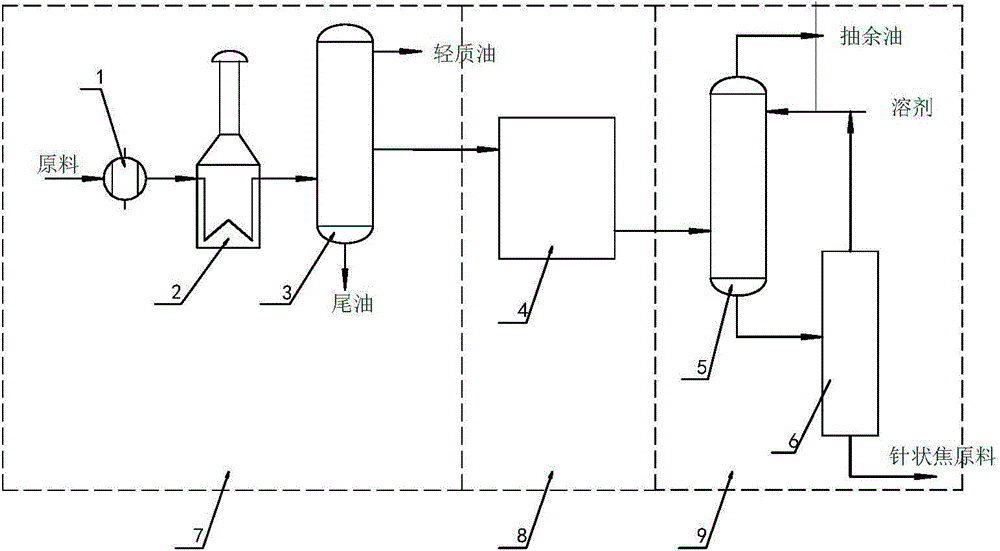

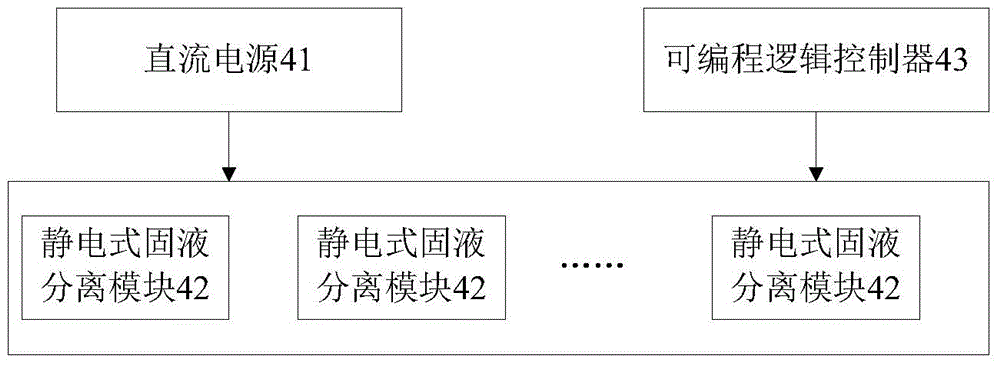

[0035] Such as figure 1 As shown, a system for producing needle coke raw materials from oil slurry in an embodiment of the present invention includes a vacuum distillation unit 7, an electrostatic solid-liquid separation unit 8, and an extraction unit 9; wherein, the vacuum distillation unit 7 communicates with the The electrostatic solid-liquid separation unit 8 is connected; the electrostatic solid-liquid separation unit 8 is connected with the extraction unit 9 through a pipeline.

[0036] Specifically, in this embodiment, the vacuum distillation unit 7 is placed in the first section of the whole system, followed by the electrostatic solid-liquid separation unit 8, and the electrostatic solid-liquid separation unit 8 is followed by the extraction unit 9. That is to say, the outlet of the vacuum distillation unit 7 is connected to the inlet of the electrostatic solid-liquid separation unit 8, the outlet of the electrostatic solid-liquid separation unit 8 is connected to the ...

Embodiment 2

[0058] The system for producing needle coke raw material from oil slurry provided in this example has the same composition as that of Example 1, except for the connections between the vacuum distillation unit, the electrostatic solid-liquid separation unit and the extraction unit. In this embodiment, the extraction unit is placed in the first section of the whole system, followed by the vacuum distillation unit, and the vacuum distillation unit is followed by an electrostatic solid-liquid separation unit. That is to say, the outlet of the extraction unit is connected to the inlet of the vacuum distillation unit, the outlet of the vacuum distillation unit is connected to the inlet of the electrostatic solid-liquid separation unit, and the outlet of the electrostatic solid-liquid separation unit outputs the needle coke raw material.

[0059] Specifically, in the extraction unit, the outlet and inlet of the extraction device are respectively connected to the solvent recovery devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com