Double-spray-head MOCVD reaction chamber

A technology of reaction chamber and shower head, which is applied in the field of reaction chamber structure of organometallic chemical vapor deposition equipment, can solve the problems of large reaction chamber size, improve power utilization efficiency, ensure temperature consistency, and reduce total gas consumption Reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to better understand the essence of the present invention, the specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings. However, this specific embodiment is only an example of the preferred technical solutions of the present invention, and should not be construed as limiting the protection scope of the present invention.

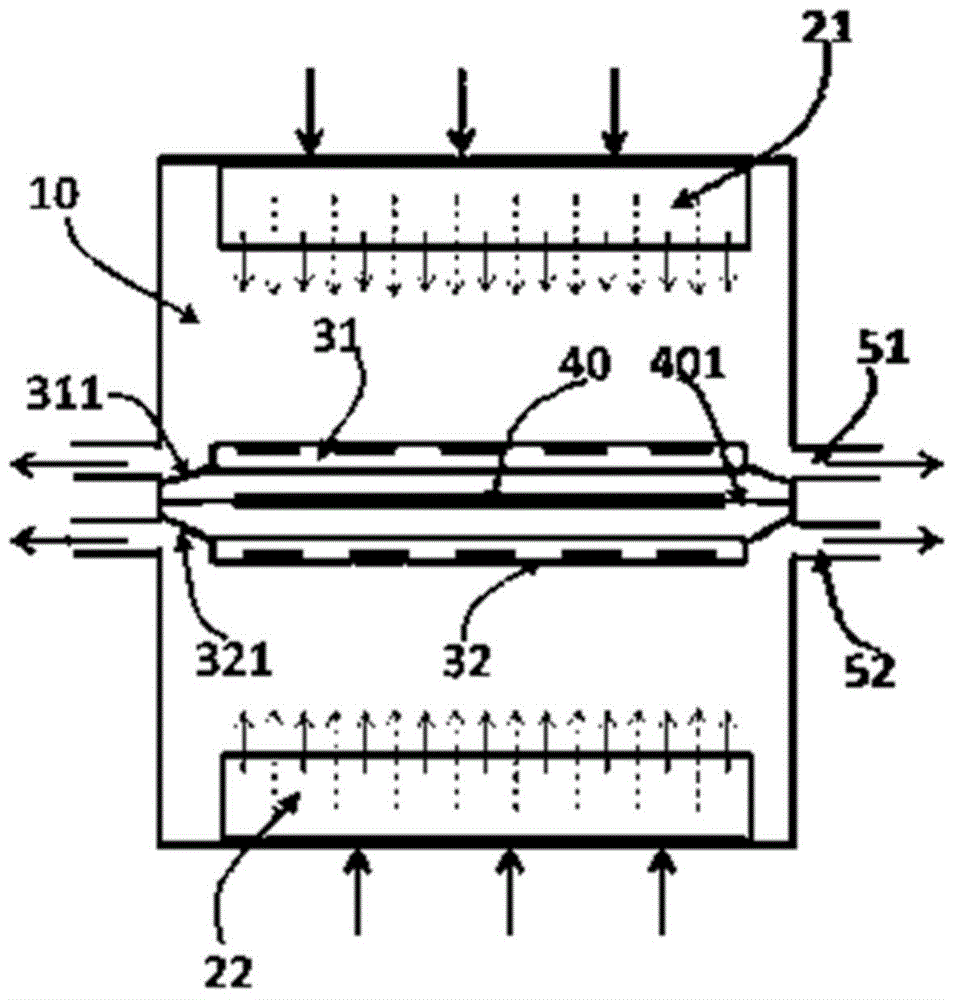

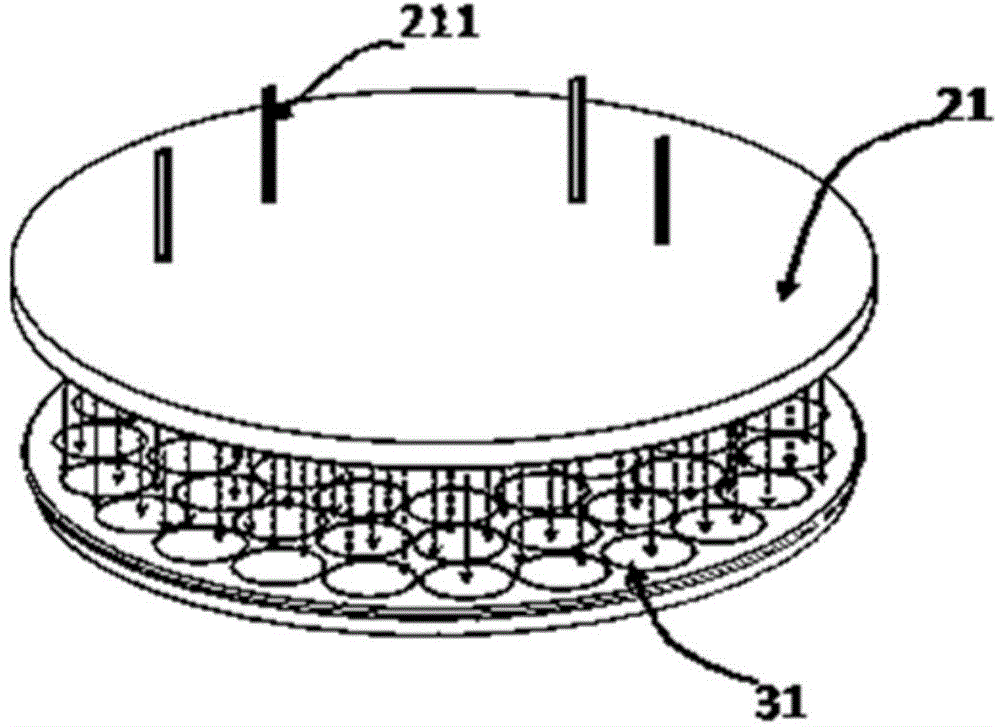

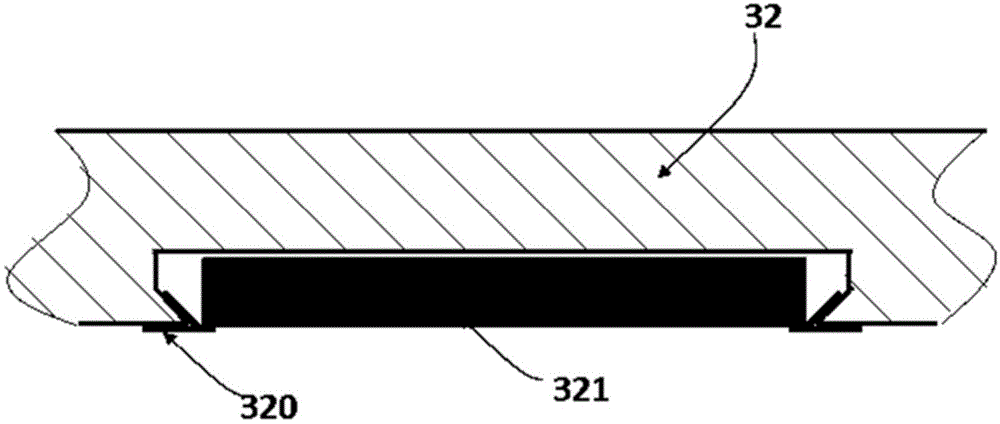

[0022] figure 1 It is a structural schematic diagram of a specific embodiment of the present invention. It should be understood that the drawings of the present disclosure focus on the structural features according to an embodiment of the present invention, and these drawings are not intended to show every single component in the device.

[0023] figure 1 A metal-organic meteorological chemical deposition reaction chamber in a specific embodiment of the present invention is shown. Wherein, the reaction chamber includes: a reaction chamber cavity 10, the reaction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com