Efficient thermal-insulation anti-oxidization aluminum water runner not adhering with aluminum

A kind of anti-alumina, launder technology, applied in low-pressure and gravity casting machines to provide high-quality aluminum alloy melt, aluminum alloy quantitative furnace is a high-pressure field, can solve the heat loss of aluminum water, solidification and crusting, affecting the quality of casting products, etc. problems, to achieve the effect of easy disassembly and maintenance, and convenient cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

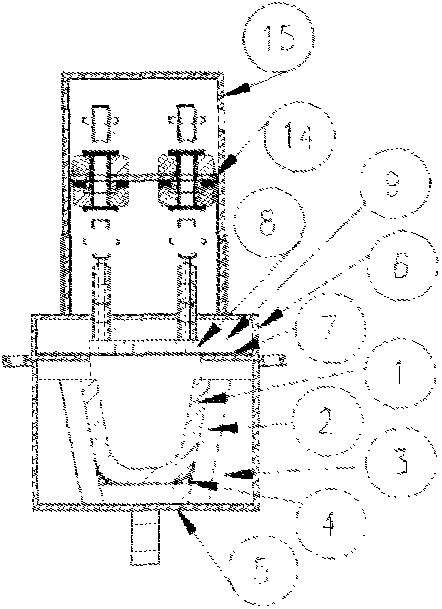

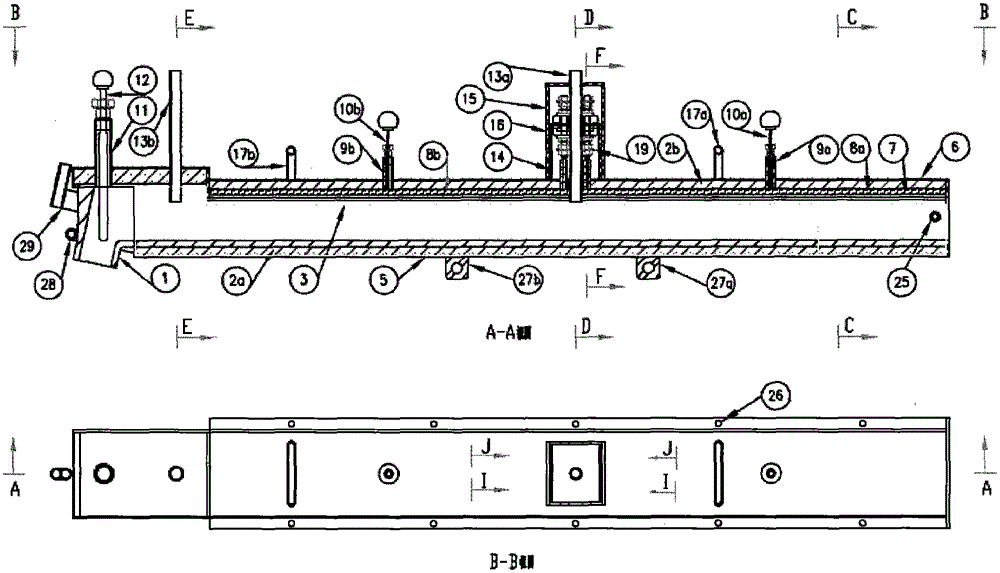

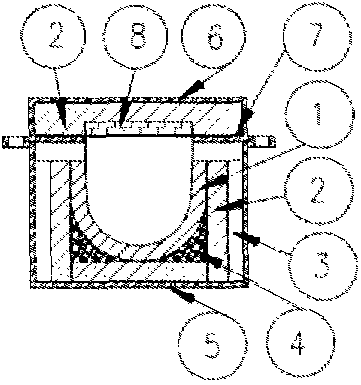

[0040] The present invention is specifically implemented in the field of aluminum alloy casting by using the "high-efficiency thermal insulation non-stick aluminum anti-alumina water flow tank" to transport high-quality aluminum alloy melt to a high-pressure casting machine, a low-pressure casting machine or a gravity casting machine.

[0041] The characteristic of the specific implementation of the present invention is to use reinforced fiberglass (RFMCS) ceramic launder (1) to prevent the aluminum alloy melt from sticking and corroding the launder. In addition, RFM CS material is light in weight, good in strength, good in crack resistance, excellent in resistance to chemical corrosion of molten aluminum, requires minimal preheating for surface dehumidification, easy to clean and handle, and low in thermal conductivity [0.43W / (m·K)500℃] )], which can reduce the heat conduction loss of the launder to a certain extent.

[0042] The feature of the specific implementation of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com