Concentrating method of low-concentration phosphoric acid waste liquid

A low-concentration, phosphoric acid technology, which is applied in chemical instruments and methods, phosphorus compounds, heating water/sewage treatment, etc., can solve the problems of high energy consumption, large equipment volume, and large investment in the concentration process, and achieve slow membrane fouling, membrane The effect of light pollution and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

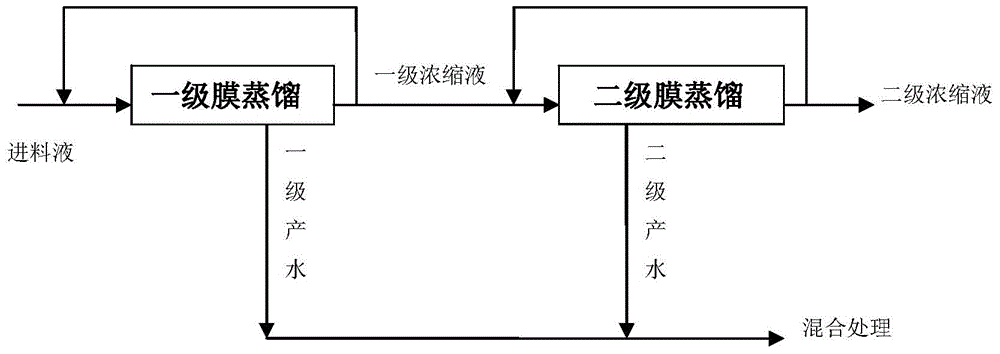

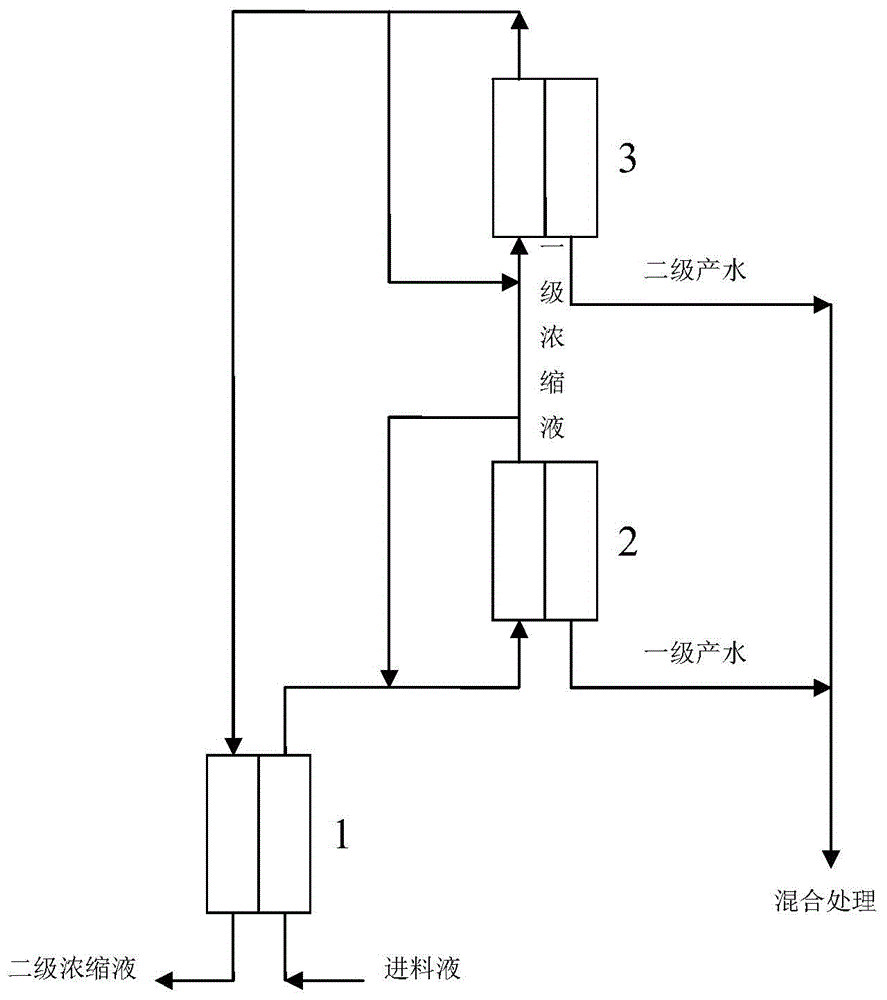

[0060] For a schematic diagram of the process, see figure 1 and figure 2 . The phosphoric acid waste liquid is dilute phosphoric acid waste liquid with a phosphoric acid mass concentration of 5%.

[0061] The operation steps are as follows:

[0062] (1) One-stage membrane distillation. First of all, after the phosphoric acid waste liquid is heated to 67°C by heating or using a polytetrafluoroethylene plate heat exchanger and the concentrated solution of the second-stage membrane distillation unit, it is pumped into the first-stage membrane distillation unit for concentration treatment, and passed through the first-stage membrane distillation unit. After the distillation circulation concentration treatment, when the mass concentration of the concentrated solution reaches 30%, the first-level concentrated solution enters step (2) to continue the second-level membrane distillation concentration treatment;

[0063] (2) Two-stage membrane distillation. The phosphoric acid was...

Embodiment 2

[0068] For a schematic diagram of the process, see figure 1 and figure 2 . The phosphoric acid waste liquid is dilute phosphoric acid waste liquid with a phosphoric acid mass concentration of 7%.

[0069] The operation steps are as follows:

[0070] (1) One-stage membrane distillation. First, the phosphoric acid waste liquid is heated or heat-exchanged to 75°C with the concentrated solution of the polytetrafluoroethylene hollow fiber heat exchanger and the secondary membrane distillation unit, and then pumped into the primary membrane distillation unit for concentration treatment. After the first-stage membrane distillation circulation concentration treatment, when the mass concentration of the concentrate reaches 35%, the first-stage concentrate enters step (2) to continue the second-stage membrane distillation concentration treatment;

[0071] (2) Two-stage membrane distillation. The phosphoric acid waste liquid with a temperature of about 73°C after the first-stage me...

Embodiment 3

[0076] For a schematic diagram of the process, see figure 1 and figure 2 . The phosphoric acid waste liquid is dilute phosphoric acid waste liquid with a phosphoric acid mass concentration of 10%.

[0077] The operation steps are as follows:

[0078] (1) One-stage membrane distillation. First, the phosphoric acid waste liquid is heated or heat-exchanged to 80°C with the concentrated solution of the polytetrafluoroethylene hollow fiber heat exchanger and the secondary membrane distillation unit, and then pumped into the primary membrane distillation unit for concentration treatment. After the first-stage membrane distillation circulation concentration treatment, when the mass concentration of the concentrate reaches 40%, the first-stage concentrate enters step (2) to continue the second-stage membrane distillation concentration treatment;

[0079] (2) Two-stage membrane distillation. The phosphoric acid waste liquid with a temperature of about 78°C after the first-stage m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Membrane pore size | aaaaa | aaaaa |

| Membrane pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com