Inner wall light partition plate and preparing method thereof

A light-weight partition board and interior wall technology, applied in the field of building board materials, can solve the problems of difficult control of board cracks, restrict development and promotion, insufficient flexural strength, etc., and achieve environmental protection, stable product quality, Good sound insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

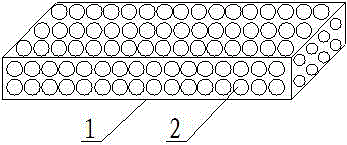

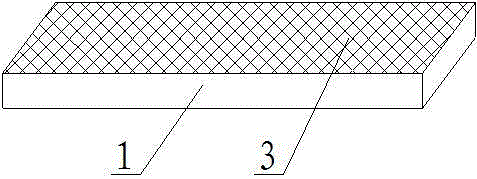

[0022] like figure 1 and figure 2 As shown, a lightweight partition board for interior walls and a preparation method thereof comprise the following steps:

[0023] Pouring slurry preparation:

[0024] Add 202.5kg of cement, 180kg of fly ash, 58.5kg of graded micropowder, and 9kg of cross-linked modified emulsion to 135kg of water, stir with a high-speed mixer (speed ≥200r / min) for 3 to 4 minutes, and add a chemical foaming agent (trace ) and stir for 3 to 4 seconds, then pour the slurry into a special mold to start foaming.

[0025] Sheet Fine Cutting:

[0026] After 3 to 4 hours, transfer the foamed blank with a certain strength to a special blank cutting saw, and perform fine cutting according to the required length, width and thickness of the interior wall lightweight partition board.

[0027] Sheet steam curing:

[0028] Put the finely cut plates on the steam trolley and enter the steam curing room for curing. Grid cloth 3 is attached to the board surface, and the ...

Embodiment 2

[0031] like figure 1 and figure 2 As shown, a lightweight partition board for interior walls and a preparation method thereof comprise the following steps:

[0032] Pouring slurry preparation:

[0033] Add 180kg of cement, 180kg of fly ash, 81kg of graded micropowder, and 9kg of cross-linked modified emulsion into 135kg of water, stir with a high-speed mixer (speed ≥200r / min) for 3 to 4 minutes, and add chemical foaming agent (trace) Stir for 3 to 4 seconds, then pour the slurry into the special mold to start foaming.

[0034] Green body fine cutting:

[0035] After 3 to 4 hours, transfer the foamed blank with a certain strength to a special blank cutting saw, and perform fine cutting according to the required length, height and thickness of the interior wall lightweight partition board.

[0036] Sheet steam curing:

[0037] Put the finely cut plates on the steam trolley and enter the steam curing room for curing. The temperature of the steam curing room is 70-80°C, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com