Oyster mushroom cultivation material

A technology for cultivation materials and oyster mushrooms, which is applied in the directions of organic fertilizers, fertilizer mixtures, and the preparation of organic fertilizers, can solve the problems of limited output, large sales volume, waste of resources and the environment, etc., and can improve the content of crude fiber and polysaccharide, iron and zinc The effect of increasing the content of the product and increasing the commodity value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

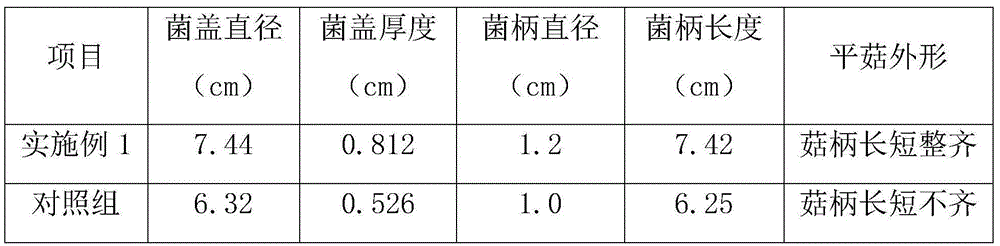

Examples

Embodiment 1

[0013] A cultivation material for oyster mushrooms, which is made of the following raw materials in proportion by weight: 70 parts of jujube sawdust, 22 parts of cottonseed hulls, 13 parts of bran, 12 parts of silkworm excrement, 15 parts of honeysuckle stems and leaves, and 10 parts of dendrobium medicine dregs , 10 parts of banana peel, 6 parts of Eupatorium adenophorum powder, 0.7 part of gypsum powder, and 0.4 part of white sugar.

[0014] Among them, a preparation method of Pleurotus ostreatus cultivation material comprises the following steps: taking jujube sawdust, cottonseed hulls, bran, silkworm excrement, honeysuckle stems and leaves, dendrobium medicinal dregs, and banana peels according to the proportioning ratio, pouring them into a grinder and pulverizing them into 80-100 mesh particles, take it out, add Eupatorium adenophorum powder, gypsum powder, and white sugar in proportion, then pour it into a blender and stir for 1.5 hours, take it out, add water in a propo...

Embodiment 2

[0017] A cultivation material for oyster mushrooms, made of the following raw materials in proportion by weight: 80 parts of jujube sawdust, 26 parts of cottonseed husks, 15 parts of bran, 15 parts of silkworm excrement, 18 parts of honeysuckle stems and leaves, and 12 parts of dendrobium medicine dregs , 13 parts of banana peel, 8 parts of Eupatorium adenophorum powder, 1.0 part of gypsum powder, and 0.6 part of white sugar.

[0018] Among them, a preparation method of Pleurotus ostreatus cultivation material comprises the following steps: taking jujube sawdust, cottonseed hulls, bran, silkworm excrement, honeysuckle stems and leaves, dendrobium medicinal dregs, and banana peels according to the proportioning ratio, pouring them into a grinder and pulverizing them into 100-mesh granules, after taking it out, add Eupatoria adenophorum powder, gypsum powder, and white sugar in proportion, then pour it into a blender and stir for 1.5 hours, take it out, add water in a proportion ...

Embodiment 3

[0021] A cultivation material for oyster mushrooms, made of the following raw materials in proportion by weight: 60 parts of jujube sawdust, 15 parts of cottonseed hulls, 10 parts of bran, 10 parts of silkworm excrement, 10 parts of honeysuckle stems and leaves, and 6 parts of dendrobium medicine dregs , 7 parts of banana peel, 5 parts of Eupatorium adenophorum powder, 0.5 part of gypsum powder, and 0.2 part of white sugar.

[0022] Among them, a preparation method of Pleurotus ostreatus cultivation material comprises the following steps: taking jujube sawdust, cottonseed hulls, bran, silkworm excrement, honeysuckle stems and leaves, dendrobium medicinal dregs, and banana peels according to the proportioning ratio, pouring them into a grinder and pulverizing them into 80-mesh granules, after taking it out, add Eupatoria adenophorum powder, gypsum powder, and white sugar in proportion, then pour it into a blender and stir for 1.5 hours, take it out, add water in a proportion of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com