Preparation method of phenolic resin composite material for storage tank

A technology of phenolic resin and composite material, applied in the field of preparation of phenolic resin composite material, can solve the problems of poor low temperature resistance, decreased mechanical properties, unsatisfactory low temperature toughness, etc., and achieves improved low temperature resistance, strong surface activity, The effect of good mechanical properties and thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

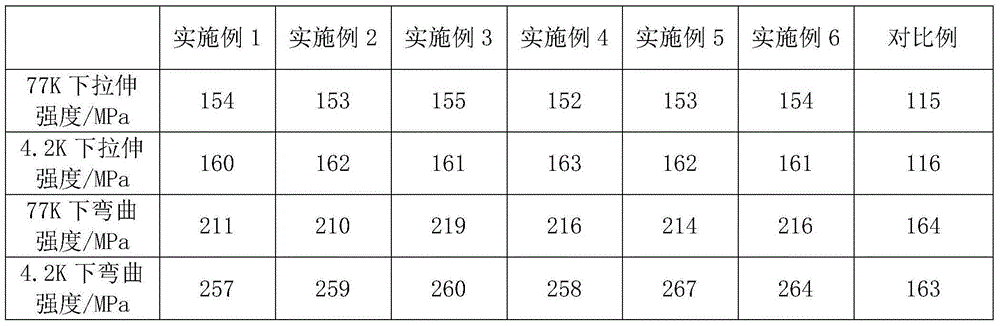

Examples

Embodiment 1

[0024] The preparation method of the phenolic resin composite material that is used for storage tank, its steps are as follows:

[0025] (1) Dissolve microcrystalline cellulose in ionic liquid, place in a water bath at 85°C and stir until microcrystalline cellulose is completely dissolved to obtain a cellulose solution, add butyric anhydride to the cellulose solution and react for 1 hour, then add acetic anhydride to continue the reaction For 2 hours, the whole reaction process was stirred continuously, and the extracted product was precipitated and washed with methanol for 3 times, and dried in a vacuum oven at 80°C for 20 hours to obtain cellulose acetate butyrate, in which microcrystalline cellulose, butyric anhydride, The molar ratio of acetic anhydride is 1:4:4;

[0026] (2) Dissolve the coupling agent in ethanol to obtain an ethanol solution of the coupling agent, dry and dehydrate the nano-silica, add the ethanol solution of the coupling agent, and stir while heating. T...

Embodiment 2

[0030] The preparation method of the phenolic resin composite material that is used for storage tank, its steps are as follows:

[0031] (1) Dissolve microcrystalline cellulose in ionic liquid, place in a water bath at 85°C and stir until microcrystalline cellulose is completely dissolved to obtain a cellulose solution, add butyric anhydride to the cellulose solution and react for 1 hour, then add acetic anhydride to continue the reaction For 2 hours, the whole reaction process was stirred continuously, and the extracted product was precipitated and washed with methanol for 3 times, and dried in a vacuum oven at 80°C for 20 hours to obtain cellulose acetate butyrate, in which microcrystalline cellulose, butyric anhydride, The molar ratio of acetic anhydride is 1:4:4;

[0032] (2) Dissolve the coupling agent in ethanol to obtain an ethanol solution of the coupling agent, dry and dehydrate the nano-silica, add the ethanol solution of the coupling agent, and stir while heating. T...

Embodiment 3

[0036] The preparation method of the phenolic resin composite material that is used for storage tank, its steps are as follows:

[0037] (1) Dissolve microcrystalline cellulose in ionic liquid, place in a water bath at 85°C and stir until microcrystalline cellulose is completely dissolved to obtain a cellulose solution, add butyric anhydride to the cellulose solution and react for 1 hour, then add acetic anhydride to continue the reaction For 2 hours, the whole reaction process was stirred continuously, and the extracted product was precipitated and washed with methanol for 3 times, and dried in a vacuum oven at 80°C for 20 hours to obtain cellulose acetate butyrate, in which microcrystalline cellulose, butyric anhydride, The molar ratio of acetic anhydride is 1:4:4;

[0038] (2) Dissolve the coupling agent in ethanol to obtain an ethanol solution of the coupling agent, dry and dehydrate the nano-silica, add the ethanol solution of the coupling agent, and stir while heating. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com