Organosilicone modification epoxy asphalt and mixture

A technology of epoxy asphalt and silicone, applied in building thermal insulation materials, building components, buildings, etc., can solve the problems of high cross-linking density, low impact strength, poor fatigue resistance, etc., and improve compatibility and oil resistance. The effect of improving and increasing adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

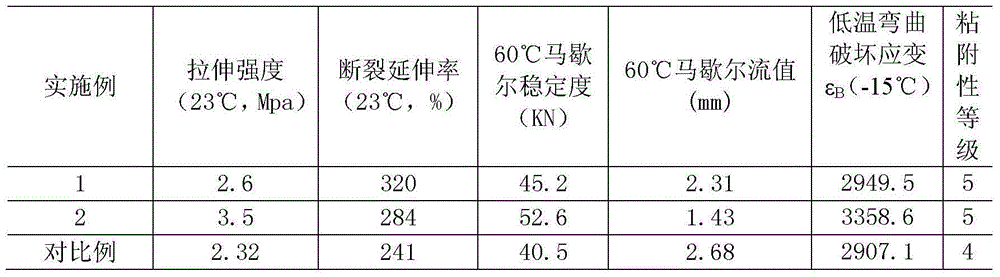

Examples

Embodiment 1

[0049] 1) Mix 10 parts of polymethyl silicone resin, 5 parts of KH-560 and 90 parts of bisphenol A epoxy resin, and stir for 20 minutes to complete the preparation of component A;

[0050] 2) Mix 135 parts of polyazelaic anhydride, 13.5 parts of dibutyl phthalate diluent, 0.01125 parts of accelerator with 125 parts of asphalt kept at 130°C, and stir at 90°C for 30 minutes to complete the preparation of component B;

[0051] 3) Mix component A and component B, and stir at 120°C for 5 minutes to obtain silicone-modified epoxy asphalt;

[0052] 4) Mix the prepared silicone-modified epoxy asphalt into the mineral aggregate, and stir at 120°C for 60s to obtain the silicone-modified epoxy asphalt mixture.

Embodiment 2

[0054]1) Mix 15 parts of polyethylphenyl silicone resin, 7.5 parts of KH-550 and 85 parts of bisphenol A epoxy resin, and stir for 15 minutes to complete the preparation of component A;

[0055] 2) Mix 35 parts of polyamide 650, 75 parts of a mixture of polyazelaic anhydride and methyltetrahydrophthalic anhydride, 7.5 parts of dibutyl phthalate diluent, 3.5 parts of xylene diluent, 0.00625 parts of accelerator and 120 ℃ Mix 112.5 parts of asphalt with heat preservation, and stir at 60°C for 30 minutes to complete the preparation of component B;

[0056] 3) Mix component A and component B, and stir at 70°C for 5 minutes to obtain silicone-modified epoxy asphalt;

[0057] 4) Mix the prepared silicone-modified epoxy asphalt into the mineral aggregate, and stir at 100°C for 60s to obtain the silicone-modified epoxy asphalt mixture.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com