A chimney anti-corrosion structure and its construction method

A construction method and chimney technology, applied in building components, building insulation materials, building types, etc., can solve problems such as multiple welding quality problems, long construction period, chimney corrosion, etc., and achieve low construction environment requirements, short construction period, hardening short time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to better understand the purpose, structure and function of the present invention, a chimney anticorrosive structure and construction method of the present invention will be described in further detail below with reference to the accompanying drawings.

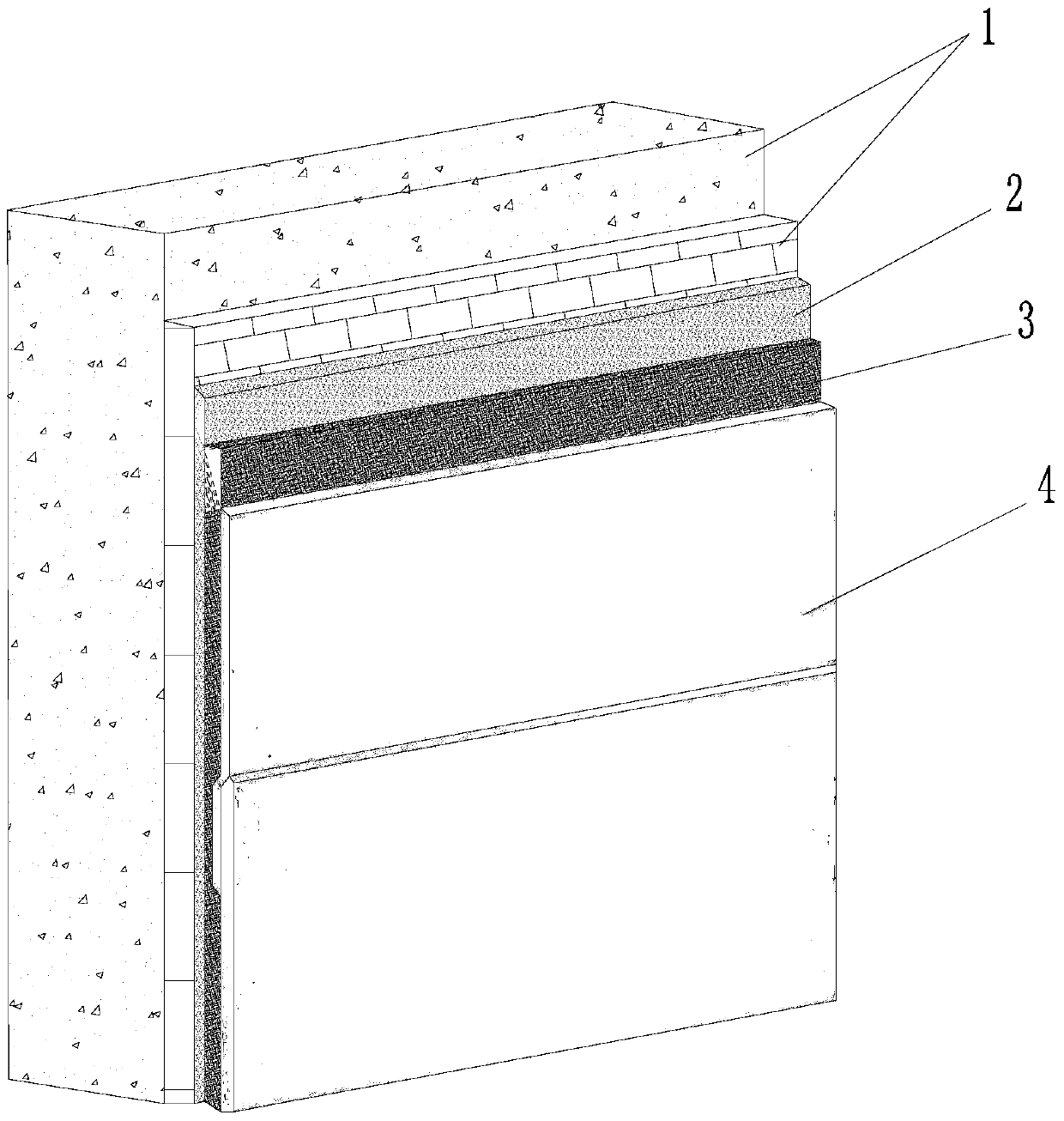

[0016] Such as figure 1 As shown, the chimney anticorrosive structure of the present invention includes a primer layer 2, an adhesive layer 3, and a titanium plate layer 4 arranged in sequence. The primer layer 2 is coated on the chimney substrate 1, and the titanium plate layer 4 passes through the adhesive layer. 3 is attached to the primer layer 2. Wherein, the titanium plate layer 4 includes a plurality of titanium plates, and the plurality of titanium plates are overlapped with each other and adhered to the undercoat layer 2 through the adhesive layer 3 to form the titanium plate layer 4.

[0017] The chimney anticorrosive structure of the present invention can adapt to the operating environment of the wet smo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com