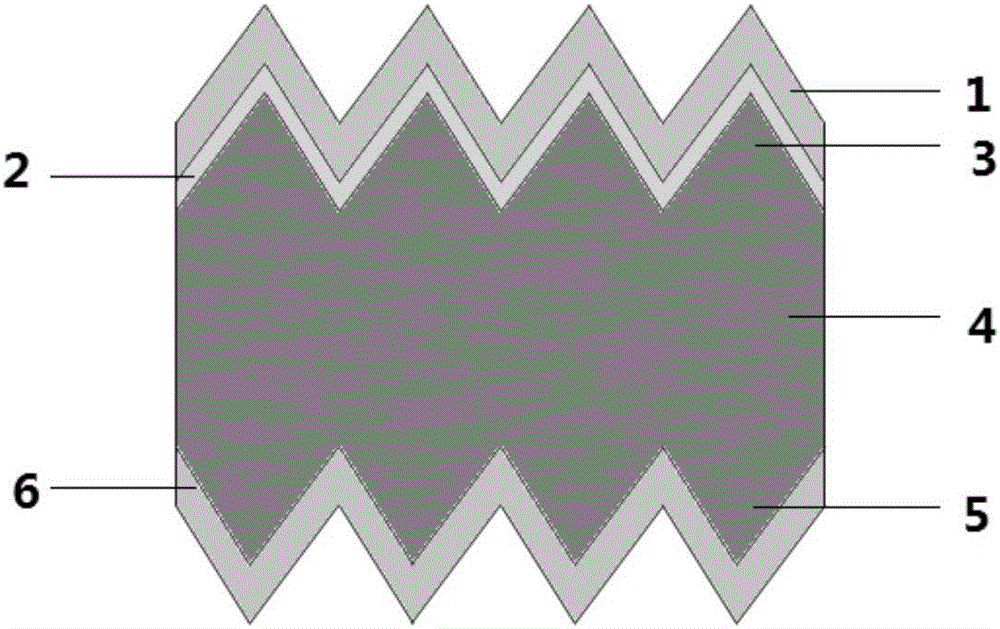

Transition metallic oxide-silicon heterojunction solar cell and preparation method thereof

A solar cell, transition metal technology, applied in circuits, photovoltaic power generation, electrical components, etc., to achieve the effect of improving separation and transmission efficiency, enhancing stability, and improving absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Prepare a transition metal oxide-silicon heterojunction solar cell according to the following steps:

[0042] (1) Use commercialized double-sided polishing, N-type monocrystalline silicon wafers with a resistivity of 1-10 ohms per centimeter and a crystal orientation of 100; clean the silicon wafers with RCA standard cleaning method, and then dry them with nitrogen. Obtain an N-type silicon substrate;

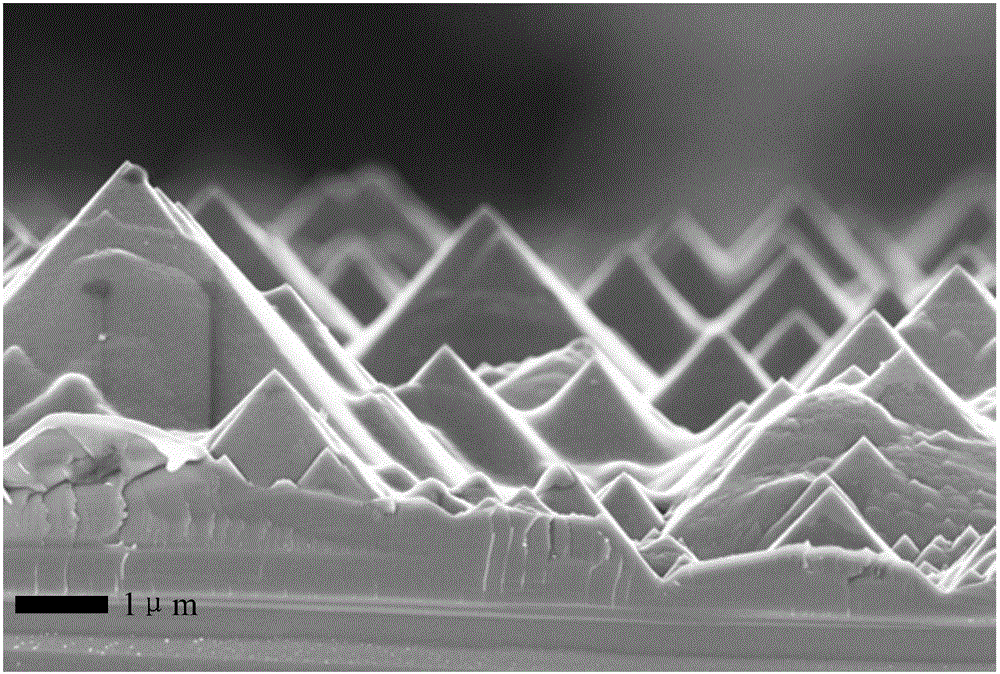

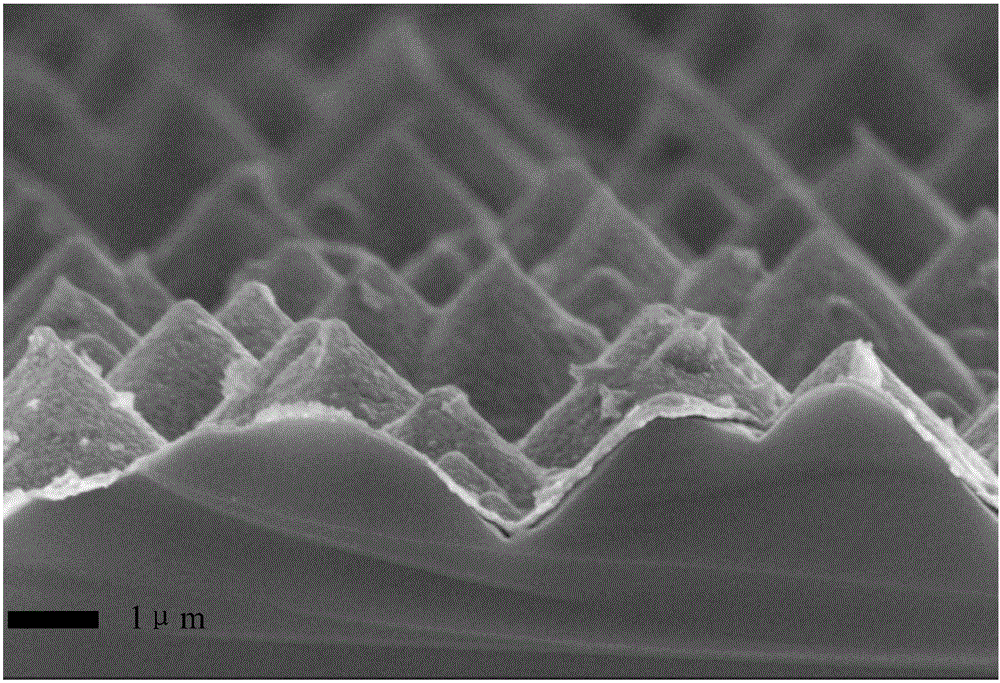

[0043] Put the N-type silicon substrate into a mixed aqueous solution with a mass fraction of 2% NaOH and a mass fraction of 10% absolute ethanol, etch at 80°C for 30 minutes; then take it out and soak it in dilute hydrochloric acid for 10 minutes to remove the residual Alkaline solution, then rinse with deionized water to obtain an N-type silicon substrate with a silicon pyramid array on the upper surface and an inverted silicon pyramid array on the lower surface; the scanning electron microscope of the silicon pyramid array is as follows figure 2 shown, from figure...

Embodiment 2

[0050] Prepare a transition metal oxide-silicon heterojunction solar cell according to the following steps:

[0051] (1) Use commercialized double-sided polishing, N-type monocrystalline silicon wafers with a resistivity of 1-10 ohms per centimeter and a crystal orientation of 100; clean the silicon wafers with RCA standard cleaning method, and then dry them with nitrogen. Obtain an N-type silicon substrate;

[0052] Put the cleaned silicon chip into a mixed aqueous solution of 2% NaOH and 10% absolute ethanol, etch at 80°C for 30 minutes; then take it out and soak it in dilute hydrochloric acid for 10 minutes to remove The residual alkali solution is rinsed with deionized water to obtain an N-type silicon substrate with a silicon pyramid array on the upper surface and an inverted silicon pyramid array on the lower surface; as can be seen from the scanning electron microscope diagram of the silicon pyramid array, The silicon pyramid array grown with anisotropy has a good arra...

Embodiment 3

[0058] Prepare a transition metal oxide-silicon heterojunction solar cell according to the following steps:

[0059] (1) Use commercialized double-sided polishing, N-type monocrystalline silicon wafers with a resistivity of 1-10 ohms per centimeter and a crystal orientation of 100; clean the silicon wafers with RCA standard cleaning method, and then dry them with nitrogen. Obtain an N-type silicon substrate;

[0060] Put the cleaned silicon chip into a mixed aqueous solution of 2% NaOH and 10% absolute ethanol, etch at 80°C for 30 minutes; then take it out and soak it in dilute hydrochloric acid for 10 minutes to remove The residual alkali solution is rinsed with deionized water to obtain an N-type silicon substrate with a silicon pyramid array on the upper surface and an inverted silicon pyramid array on the lower surface; as can be seen from the scanning electron microscope diagram of the silicon pyramid array, The silicon pyramid array grown with anisotropy has a good arra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Short circuit current density | aaaaa | aaaaa |

| Open circuit voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com