Asymmetric succinate type gemini surfactant and preparation method thereof

A surfactant and succinate technology, which is applied in the preparation of sulfonate, chemical instruments and methods, organic chemistry, etc., can solve the problems of high production cost, application and marketing restrictions, and difficulty in large-scale industrial production. Achieve the effects of low price, wide range of sources and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

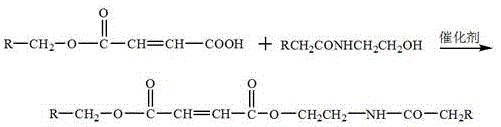

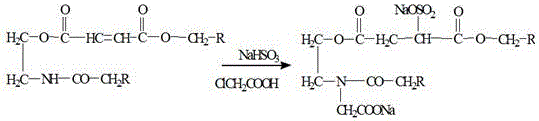

Method used

Image

Examples

Embodiment 1

[0026] Take 32.7 parts by mass of fatty acid monoethanolamide and 25.74 parts by mass of dodecyl butenedioic acid monoester, add them to a three-necked flask, add 1.5 parts by mass of boric acid as a catalyst, heat up to 90°C, and react for 6.5 hours;

[0027] Cool down to 85°C, add sodium bisulfite, and react for 2 hours;

[0028] Add chloroacetic acid, react for 3 hours, and adjust the pH to 7 during the reaction;

[0029] Washing with absolute ethanol, filtering and drying to obtain an asymmetric succinate-type Gemini surfactant.

Embodiment 2

[0031] Take 28.5 parts by mass of fatty acid monoethanolamide and 28.6 parts by mass of dodecyl butenedioic acid monoester, add them to a three-necked flask, add 1 part by mass of boric acid as a catalyst, heat up to 105°C, and react for 5.5 hours;

[0032] Cool down to 85°C, add sodium bisulfite, and react for 2.5 hours;

[0033] Add chloroacetic acid, react for 2.5 hours, and adjust the pH to 7 during the reaction;

[0034] Washing with absolute ethanol, filtering and drying to obtain an asymmetric succinate-type Gemini surfactant.

Embodiment 3

[0036] Take 32.7 parts by mass of fatty acid monoethanolamide and 25.74 parts by mass of dodecyl butenedioic acid monoester, add them to a three-necked flask, add 1.5 parts by mass of boric acid as a catalyst, heat up to 90°C, and react for 6.5 hours;

[0037] Cool down to 85°C, add sodium bisulfite, and react for 2 hours;

[0038] Add chloroacetic acid, react for 3 hours, and adjust the pH to 7 during the reaction;

[0039] Washing with absolute ethanol, filtering and drying to obtain an asymmetric succinate-type Gemini surfactant.

[0040] Unsymmetrical succinate type Gemini surfactant (C 12 -C 12 ) The first step reaction infrared NMR data is as follows:

[0041] 3444.24 cm -1 is the absorption peak of amide hydrogen; 2854.25cm -1 and 2924.39cm -1 The absorption peak at -CH 3 and -CH 2 The stretching vibration absorption peak of -; 1593 cm -1 is the amide absorption peak; 2667.83 cm -1 with 1732.63 cm -1 Ester carbonyl characteristic absorption peak appears; 1281...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com