Sewage treatment system special for numerical control machining workshop

A technology of sewage treatment system and processing workshop, which is applied in the field of numerical control to achieve the effects of convenient use, low cost and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

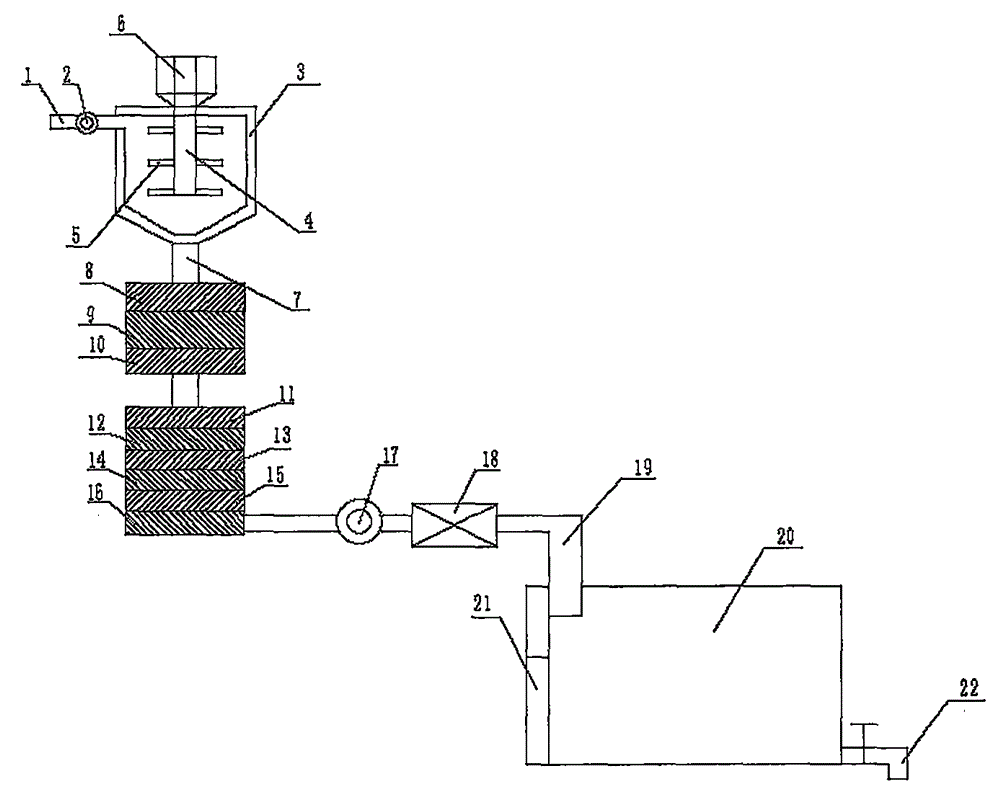

[0010] like figure 1 As shown, this specific embodiment adopts the following technical solutions: a special sewage treatment system for CNC machining workshops, including water inlet pipe 1, flow meter 2, stirring tank 3, stirring shaft 4, stirring plate 5, motor 6, water pipe 7. High-density fiber yarn 8, micro-electrolysis filler 9, activated carbon layer 10, filter layer 11, biological treatment area 12, aeration oxidation area 13, heavy metal reaction area 14, acid-base neutralization area 15, purification and disinfection area 16, water pump 17. Water quality detector 18, water outlet pipe 19, water storage chamber 20, water level gauge 21 and water valve 22; said flow meter 2 is arranged on the water inlet pipe 1; said water inlet pipe 1 is arranged on the upper end of the mixing tank 3; A stirring shaft 4 is flexibly connected to the chamber of the stirring tank 3; several stirring blades 5 are integrally formed on the stirring shaft 4; the input shaft of the stirring s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com