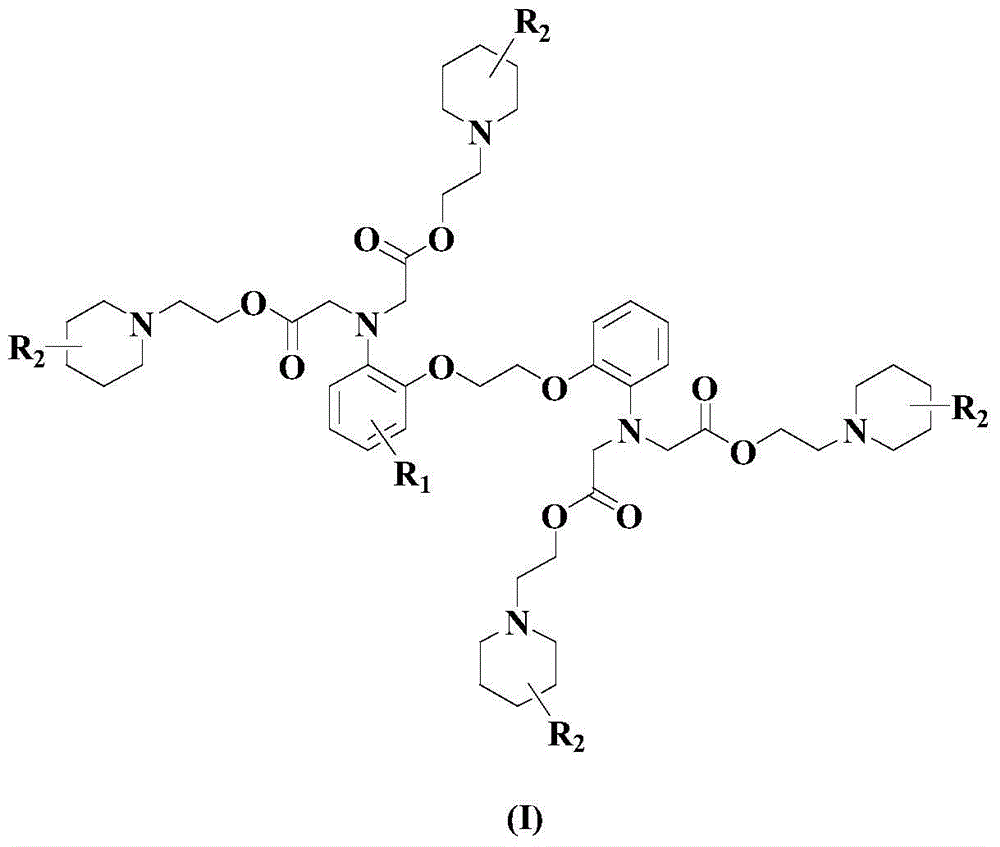

A kind of calcium ion selective chelating agent and its preparation method and application

A calcium ion and selective technology, applied in chemical instruments and methods, organic compound/hydride/coordination complex catalysts, drug combinations, etc., can solve problems such as impractical application, difficult experimental methods, and inconvenient use. Achieve the effects of good industrial production potential, excellent biological activity and good yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0056] Preparation Example 1: Preparation of Catalyst C1

[0057] (1) SBA-15 mesoporous molecular sieves were calcined at 500°C for 40 minutes, and then naturally cooled to room temperature to obtain primary treated molecular sieves;

[0058] (2) placing the primary treated molecular sieve in a water vapor atmosphere at 500° C. for 60 minutes to obtain a secondary treated molecular sieve;

[0059] (3) Add secondary treatment molecular sieve and ionic liquid N,N,N',N'-tetramethyl-N,N'-disulfonic acid propylpropylenediamine bisulfate to an appropriate amount of ethyl acetate (where , the mass of the secondary treatment molecular sieve and N,N,N',N'-tetramethyl-N,N'-disulfonic acid propylpropylenediamine bisulfate is 1:0.4), at 40°C Thoroughly stir and mix for 8 hours, then filter, wash the resulting solid with deionized water 2-3 times, and then vacuum-dry to obtain catalyst C1.

preparation example 2

[0060] Preparation Example 2: Preparation of Catalyst C2

[0061] (1) SBA-15 mesoporous molecular sieves were calcined at 520°C for 30 minutes, and then naturally cooled to room temperature to obtain primary treated molecular sieves;

[0062] (2) placing the primary treated molecular sieve in a water vapor atmosphere at 500°C for 70 minutes to obtain a secondary treated molecular sieve;

[0063] (3) Add the secondary treatment molecular sieve and ionic liquid N,N,N',N'-tetramethyl-N,N'-disulfonic acid propylpropylenediamine bisulfate into an appropriate amount of chloroform (wherein, the The mass ratio of the secondary treatment molecular sieve to N,N,N',N'-tetramethyl-N,N'-disulfonic acid propylpropylenediamine bisulfate is 1:0.5), fully Stir and mix for 6 hours, then filter, wash the resulting solid with deionized water for 2-3 times, and then vacuum-dry to obtain catalyst C2.

preparation example 3

[0064] Preparation Example 3: Preparation of Catalyst C3

[0065] (1) SBA-15 mesoporous molecular sieves were calcined at 550°C for 20 minutes, and then naturally cooled to room temperature to obtain primary treated molecular sieves;

[0066] (2) placing the primary treated molecular sieve in a water vapor atmosphere at 500°C for 80 minutes to obtain a secondary treated molecular sieve;

[0067] (3) Add the secondary treatment molecular sieve and ionic liquid N,N,N',N'-tetramethyl-N,N'-disulfonic acid propyl propylene diamine bisulfate into an appropriate amount of benzene (wherein, the The mass ratio of the secondary treatment molecular sieve to N,N,N',N'-tetramethyl-N,N'-disulfonic acid propylpropylenediamine bisulfate is 1:0.6), fully Stir and mix for 4 hours, then filter, wash the resulting solid with deionized water for 2-3 times, and then vacuum-dry to obtain catalyst C3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com