A method for extracting fucoidan with high yield and high proportion of fucose

A technology of fucoidan and extraction method, which is applied in the field of seaweed processing and utilization, can solve the problems of low quality fucoidan, many impurities of fucoidan, and insufficient quality for use, and achieve environmental protection, mild extraction conditions, and high extraction efficiency. short time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

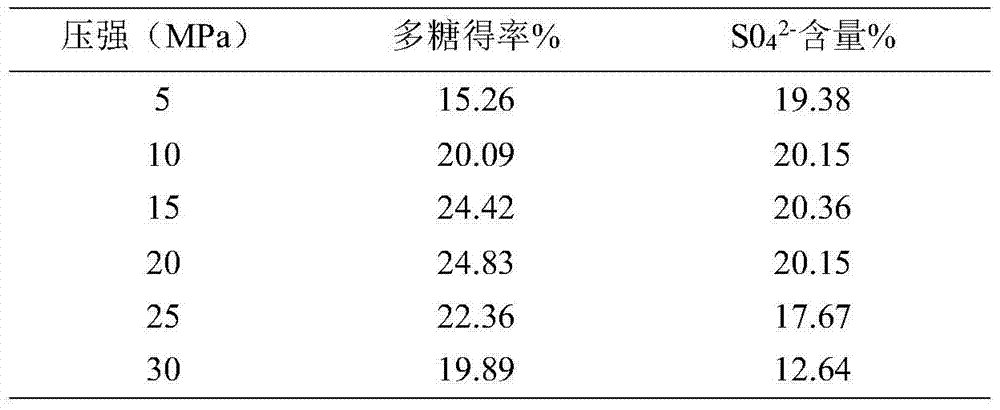

[0038] Example 1: Direct extraction of fucoidan by high-pressure homogenization

[0039] Weigh 50g of dried mozuku, pulverize with a pulverizer, sieve through a 100-mesh sieve, add water according to the mass ratio of dried mozuku:water=1:30, soak for a period of time, stir well, and homogenize once under 15Mpa.

[0040] After high-pressure homogenization, centrifuge at 4000rpm for 15min, take the centrifuged supernatant (i.e. extract), concentrate the extract, add 3 volumes of absolute ethanol per L of extract, mix well, and let stand to obtain a precipitate . The precipitate is filtered and vacuum-dried to obtain refined fucoidan.

[0041] 15.48 g of fucoidan was obtained with a yield of 30.96% (product / raw material dry weight×100), a purity of 88.22%, and an organic sulfate content of 22.03%. The molar content of fucose in the fucoidan is 73.84%.

Embodiment 2

[0042] Example 2: Extraction of fucoidan by high pressure homogenization method combined with chemical degradation method (1)

[0043] Weigh 0.5kg of fresh mozuku (dry weight is about 20-25g), wash it, add 1.5kg of water (that is, the ratio of material to water is 1:60-1:75), and homogenize once at 20Mpa. Then centrifuge at 5000rpm for 10min, and take the centrifuged supernatant (ie extract). Concentrate the extract to 1 / 2 of the original volume, and then add 8 mL of 30% H 2 o 2 , 60°C water bath, degrade for 1h, adjust the pH of the degradation solution to neutral with 1M NaOH solution, and then add catalase to react for 20min. The degradation solution flows through ultrafiltration columns with a molecular weight cut-off of 30KD and 10KD, and the 10-30KD concentrated solution is collected to obtain a retentate. Add 4 times the volume of absolute ethanol to the retentate, mix well, and let it stand for 24 hours to collect solid sediment. ; The precipitate was filtered throu...

Embodiment 3

[0045] Example 3: Extraction of fucoidan by high pressure homogenization method combined with chemical degradation method (2)

[0046] Weigh 0.5kg of fresh mozuku (dry weight is about 20-25g), clean it, add 4kg of water (that is, the ratio of material to water is 1:160-1:200), and homogenize 3 times under 10Mpa. Centrifuge and take the supernatant (ie extract). Concentrate the extract to 1 / 4 of the original volume, and then add 5 mL of 30% H 2 o 2 , 50°C water bath, degrade for 4h, adjust the pH of the degradation solution to neutral with 1M NaOH solution, and then add catalase to react for 10min. The degradation solution flows through the ultrafiltration column with a molecular weight cut-off of 30KD and 10KD, and the concentrated solution of 10-30KD is collected to obtain the retentate, and 4 times the volume of absolute ethanol is added to the retentate, mixed, left standing, and the solid sediment is collected; The precipitate was filtered through a plate frame and drie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com