Paper tuber adhesive, and production method thereof

A production method and technology of paper tube glue, applied in the direction of monocarboxylate copolymer adhesive, adhesive type, adhesive additive, etc., can solve the problem of poor compressive strength and creep resistance of paper tube, paper tube resistance Reduced compressive strength, low bonding strength and other problems, to achieve the effect of short initial bonding time, good initial bonding force and good stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

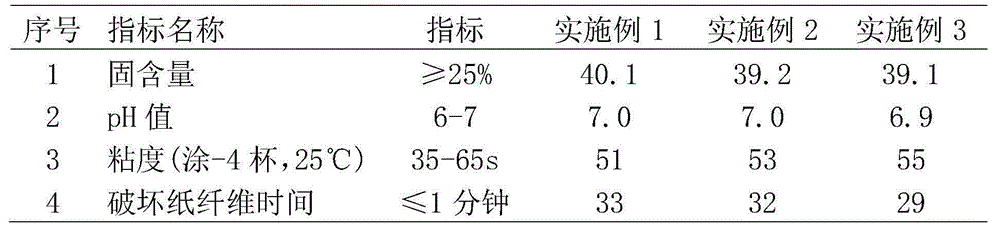

Examples

Embodiment 1

[0028] A kind of production method of paper tube glue, comprises the steps:

[0029] 1) Material preparation: prepare the following raw materials in parts by weight: 32 parts of vinyl acetate, 10 parts of dried monk fruit, 7 parts of polyvinyl alcohol, 3 parts of ethylene glycol, 0.5 parts of polyacrylamide, 1.5 parts of dibutyl phthalate, 0.5 parts of emulsifier, 0.5 parts of potassium persulfate, 130 parts of purified water;

[0030] 2) Treatment of Luo Han Guo:

[0031] ①High-pressure treatment: After chopping or pulverizing the Luo Han Guo, put it into a high-pressure tank, pressurize it to 30MPa, make the pressure uniform, and keep it for 10 minutes to return to normal pressure;

[0032] ②Steam explosion: put the material obtained in step ① into the steam explosion tank, the explosion pressure is 3.5Mpa, and the holding time is maintained at 200s;

[0033] ③Decoction and decolorization: Add the material obtained in step ① into pure water of equal weight and decoct twice...

Embodiment 2

[0042] A kind of production method of paper tube glue, comprises the steps:

[0043] 1) Material preparation: prepare the following raw materials in parts by weight: 38 parts of vinyl acetate, 8 parts of Luo Han Guo, 9 parts of polyvinyl alcohol, 2 parts of ethylene glycol, 1.5 parts of polyacrylamide, 0.5 parts of dibutyl phthalate, emulsified 1.5 parts of preservative, 0.5 parts of potassium persulfate, 110 parts of purified water;

[0044] 2) Treatment of Luo Han Guo:

[0045] ①High-pressure treatment: After chopping or crushing Luo Han Guo, put it into a high-pressure tank, pressurize it to 30MPa, make the pressure uniform, and keep it for 15 minutes to return to normal pressure;

[0046] ②Steam explosion: Put the material obtained in step ① into the steam explosion tank, the explosion pressure is 3.0Mpa, and the holding time is maintained at 180s;

[0047] ③Decoction and decolorization: Add the material obtained in step ① into pure water of equal weight and decoct twice...

Embodiment 3

[0056] A kind of production method of paper tube glue, comprises the steps:

[0057] 1) Material preparation: Prepare the following raw materials in parts by weight: 35 parts of vinyl acetate, 10 parts of fresh Luo Han Guo, 8 parts of polyvinyl alcohol, 2.5 parts of ethylene glycol, 1 part of polyacrylamide, 1 part of dibutyl phthalate, 1 part of emulsifier, 0.5 part of potassium persulfate, 120 parts of purified water;

[0058] 2) Treatment of Luo Han Guo:

[0059] ①High-pressure treatment: After chopping or pulverizing the Luo Han Guo, put it into a high-pressure tank, pressurize it to 25MPa, make the pressure uniform, and keep it for 20 minutes to return to normal pressure;

[0060] ②Steam explosion: Put the material obtained in step ① into the steam explosion tank, the explosion pressure is 3.5Mpa, and the holding time is maintained at 150s;

[0061] ③Decoction and decolorization: Add the material obtained in step ① into pure water of equal weight and decoct twice, each ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com