A method for efficient anaerobic fermentation of organic waste resources in intensive vegetable areas to produce biogas

A vegetable waste and organic waste technology, applied in the field of biogas, can solve the problems of harmful gas pollution to the environment, lack of raw materials for household biogas digesters, long processing time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] Example 1: Separate anaerobic fermentation of vegetable waste in intensive vegetable area.

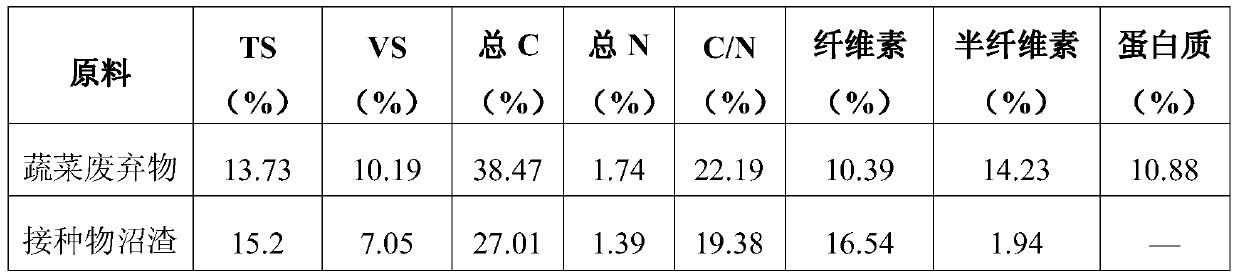

[0060] The characteristics of vegetable waste and inoculum are shown in Table 1.

[0061] Table 1 Characteristics of vegetable waste and inoculum

[0062]

[0063] A method for efficient anaerobic fermentation of organic waste resources in an intensive vegetable area to produce biogas, comprising the following steps:

[0064] (1) The collected vegetable waste is pulverized to 1.5cm and set aside;

[0065] (2) Take 480 g of crushed vegetable waste, add 60 g of anti-acidification microbial preparation and mix, add water and stir evenly, adjust the C / N ratio after mixing to 25:1, and the water content is 88%, to obtain the mixed material;

[0066] The acidification-inhibiting microbial preparation is prepared by mixing and uniformly obtaining fermented liquid obtained from Bacillus subtilis, Bacillus megaterium, Pseudomonas fluorescens, Saccharomyces cerevisiae, and Pichia pas...

Embodiment 2

[0068] Example 2: Mixed anaerobic fermentation of vegetable waste in intensive vegetable area and cow manure.

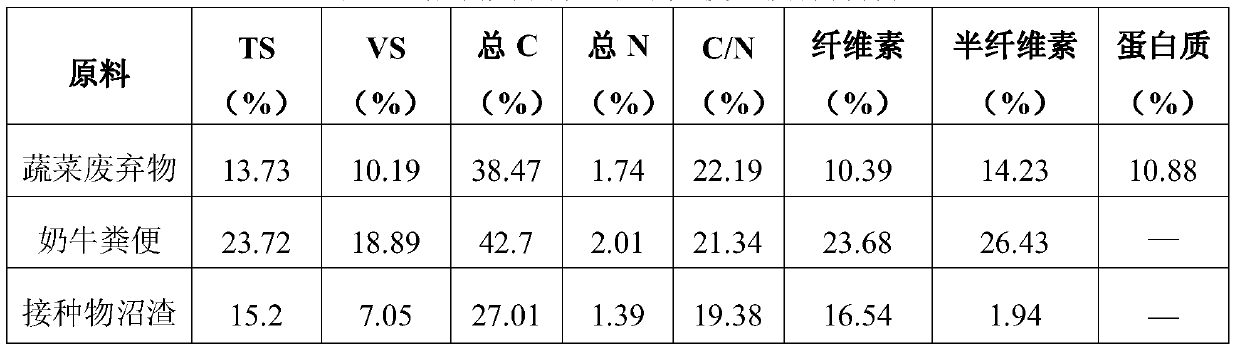

[0069] The characteristics of the vegetable waste, cow manure and inoculum are shown in Table 2.

[0070] Table 2 Characteristics of vegetable waste, cow manure and inoculum

[0071]

[0072] A method for efficient anaerobic fermentation of organic waste resources in an intensive vegetable area to produce biogas, comprising the following steps:

[0073] (1) The collected vegetable waste is pulverized to 1.5cm and set aside;

[0074] (2) Take 300 g of crushed vegetable waste, add 100 g of fresh cow feces and mix, add water and stir evenly, adjust the C / N ratio after mixing to 25:1, and the water content is 88%, to obtain a mixed material;

[0075] (3) Add 700 g of inoculum to the mixed material of step (2), add water to adjust the material TS to 10.0%, and adjust the pH value to 7.8 to obtain the fermented material, which is anaerobically fermented at a temperatu...

Embodiment 3

[0076] Example 3: Mixed anaerobic fermentation of vegetable waste and corn stalks in intensive vegetable area.

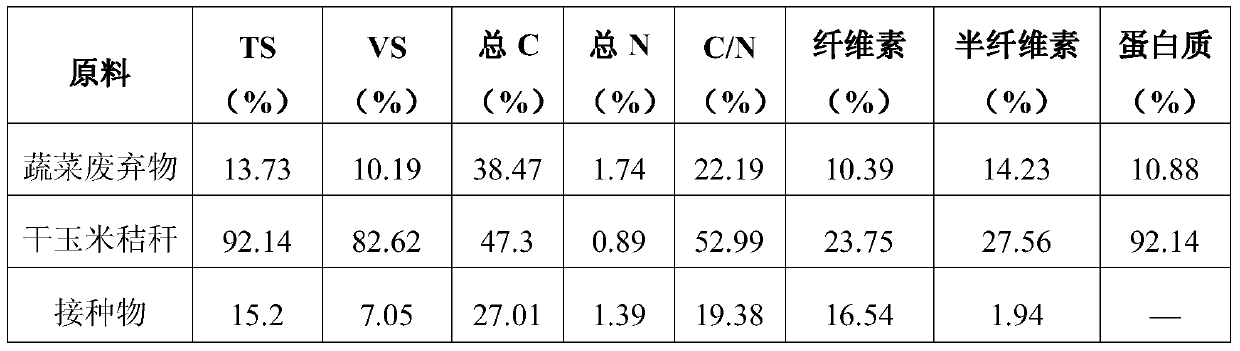

[0077] The characteristics of vegetable waste, corn stover and inoculum are shown in Table 3.

[0078] Table 3 Characteristics of vegetable waste, dairy manure and inoculum

[0079]

[0080]A method for efficient anaerobic fermentation of organic waste resources in an intensive vegetable area to produce biogas, comprising the following steps:

[0081] (1) The collected vegetable waste is pulverized to 2cm and set aside;

[0082] (2) Add fresh cow feces and stalks treated with bacterial agents to the crushed vegetable waste, mix them, add water and stir evenly, adjust the C / N ratio after mixing to 26:1, and the water content to 88%, to obtain a mixed material ; The mass ratio of fresh cow manure, straw pretreated by bacterial agents, and crushed vegetable waste is: 2:3:4;

[0083] The straw treated with the bacterial agent is obtained as follows: crush the dry ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com