Pretreatment reagent and method for rapid detection of heavy metal cadmium in grain crops

A technology of heavy metals and reagents, which is applied in the field of heavy metal detection, can solve the problems of inability to improve equipment utilization efficiency and long pretreatment time, and achieve the effects of ensuring practicability, increasing extraction recovery rate, and accelerating consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

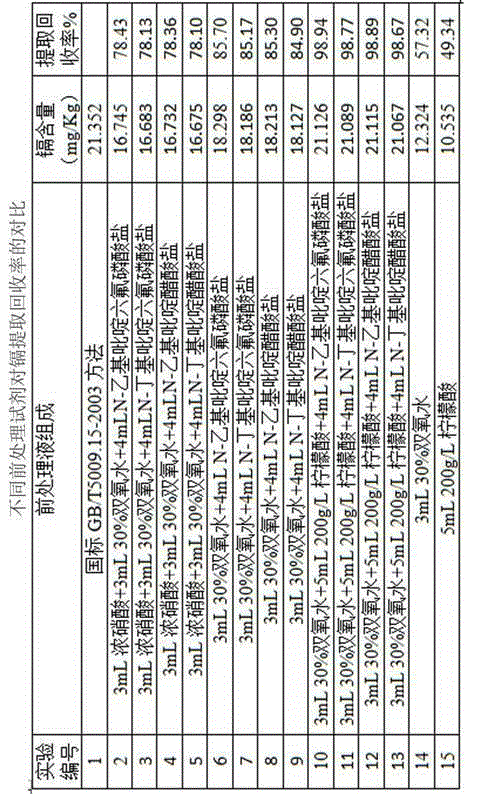

[0030] Example 1 The comparison of different pretreatment reagents to the recovery rate of cadmium extraction

[0031] The sample in this experiment is cadmium-rich rice, which is obtained by soaking the rice in cadmium nitrate solution for 15 days. The sample is dried in the sun, crushed, and stored in a refrigerator.

[0032] 1.1 Determination of cadmium content in cereal crops by national standard pretreatment method

[0033] Weigh 1.000g of the sample into a polytetrafluoroethylene inner tank, add 2-4mL of nitric acid to soak for 12h, then add 2mL of hydrogen peroxide, cover the inner cover, put it into a constant temperature drying oven, and dry it at 130 o Keep at C for 4 hours, and after cooling to room temperature, transfer the digestive solution into a 25mL volumetric flask for constant volume; at the same time, conduct a blank control test throughout the process.

[0034] 1.2 The present invention discloses pretreatment reagents and methods for determining cadmium c...

Embodiment 2

[0038] Soak wheat in cadmium nitrate solution for 15 days to obtain cadmium-rich cereal crops, dry them and crush them, accurately weigh 1.000g of cereal crop samples and place them in a 25mL polytetrafluoroethylene digestion tank, add 1mL 30% hydrogen peroxide, 3mL N-ethylpyridine hexafluorophosphate, 6mL 200g / L citric acid. After adding the above-mentioned treatment reagent, microwave treatment for 3 minutes, then add a certain amount of NaOH solution to neutralize it to near neutrality, transfer it to a 25mL volumetric flask after cooling, and add deionized water to dilute to 25mL. At the same time, the sample was processed according to the national standard method (GB / T5009.15-2003): take 1.000 g of the pulverized sample and put it in a polytetrafluoroethylene inner tank, add 3 mL of nitric acid to soak overnight, and then add 2 mL of 30% hydrogen peroxide. Close the inner lid and put in 130 o Keep in an oven at C for 4h, transfer it to a 25mL volumetric flask after cooli...

Embodiment 3

[0040] Soak corn in cadmium nitrate solution for 15 days to obtain cadmium-rich cereal crops, dry them and crush them, accurately weigh 1.000g of cereal crop samples and place them in a 25mL polytetrafluoroethylene digestion tank, add 3mL 30% hydrogen peroxide, 6mL N-ethylpyridine acetate, 2mL 200g / L citric acid. After adding the above-mentioned treatment reagent, microwave treatment for 7 minutes, then add a certain amount of NaOH solution to neutralize it to near neutrality, transfer it to a 25mL volumetric flask after cooling, and add deionized water to dilute to 25mL. At the same time, the samples were processed according to the national standard method (GB / T5009.15-2003): 1.000 g of crushed cereal crop samples were placed in a polytetrafluoroethylene inner tank, soaked overnight in 3 mL of nitric acid, and then added with 2 mL of hydrogen peroxide. Close the inner lid and put in 130 oKeep in an oven at C for 4h, transfer it to a 25mL volumetric flask after cooling to roo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com