Chemical stability evaluating method of fluorapatite ceramic solidification body

A technology of chemical stability and ceramic solidification, which is applied in color/spectral characteristic measurement, thermal excitation analysis, material excitation analysis, etc., and can solve problems such as unreported and lack of experimental basis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

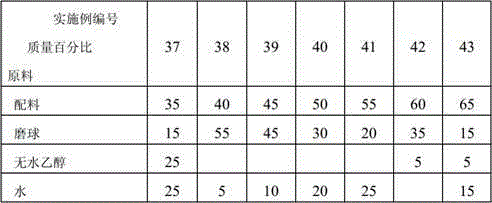

Embodiment 1

[0033] with Ca 2 P 2 o 7 , CaF 2 、Sm 2 o 3 As raw material, according to the chemical formula Ca 9.85 SM 0.1 (PO 4 ) 6 f 2Weigh the raw materials of each component for batching, according to the batching: grinding ball: absolute ethanol or / and water at a mass percentage of 35:15:50, mix them in a planetary ball mill and grind for 2 hours, and the obtained mixture is dried, The dried powder can be obtained, add polyvinyl alcohol sol of 3% of the dried powder mass, and then use a sieve to mix and granulate. Material; put the granulated material into a steel mold, press and form it with a pressure of 8 MPa on a hydraulic press, and then perform cold isostatic pressing on a cold isostatic press with a pressure of 80 MPa to obtain a molded green body; at 400 ° C Heat-treat the molded green body at high temperature for 5 hours for debinding, then put the degummed green body into a vacuum hot-press sintering furnace, and carry out vacuum hot-press sintering at a temperature...

Embodiment 2

[0035] with Ca 2 P 2 o 7 , CaF 2 、Sm 2 o 3 As raw material, according to the chemical formula Ca 7.75 SM 1.5 (PO 4 ) 6 f 2 Weigh the raw materials of each component for batching, according to the batching: grinding ball: absolute ethanol or / and water at a mass percentage of 55:25:20, mix them in a planetary ball mill and grind for 3 hours, and the obtained mixture is dried, The dried powder can be obtained, add polyvinyl alcohol sol with a mass of 6% of the dried powder, and then use a sieve to mix and granulate. Material; put the granulated material into a steel mold, press and form it with a pressure of 21 MPa on a hydraulic press, and then perform cold isostatic pressing on a cold isostatic press with a pressure of 170 MPa to obtain a molded green body; at 500 ° C The molded green body is heat-treated at high temperature for 7 hours for debinding, and then the degummed green body is put into a vacuum hot-pressing sintering furnace, and vacuum hot-pressing sinterin...

Embodiment 3

[0037] with Ca 2 P 2 o 7 , CaF 2 、Sm 2 o 3 As raw material, according to the chemical formula Ca 5.5 SM 3 (PO 4 ) 6 f 2 Weigh the raw materials of each component for batching, according to the batching: grinding ball: absolute ethanol or / and water in a mass percentage of 65:20:15, mix them in a planetary ball mill and grind for 5 hours, and the obtained mixture is dried. The dried powder can be obtained, add polyvinyl alcohol sol with a mass of 10% of the dried powder, and then use a sieve to mix and granulate. Material; put the granulated material into a steel mold, press and form it on a hydraulic press with a pressure of 35 MPa, and then perform cold isostatic pressing on a cold isostatic press with a pressure of 260 MPa to obtain a molded green body; at 600 ° C The molded green body is heat-treated at high temperature for 10 hours for debinding, and then the degummed green body is put into a vacuum hot-pressing sintering furnace, and vacuum hot-pressing sintering...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com