Random laser, random resonant cavity manufacture method and small particle concentration detection method

A random laser and random laser technology, applied in the laser field, can solve the problems of poor output laser controllability, long gain length, gain discontinuity, etc., and achieve controllable output, good gain effect, and reduced gain length.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

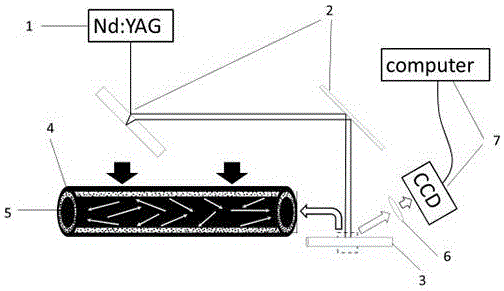

[0045] The invention discloses a random laser, which includes:

[0046] Pumping light source 1, used to generate pumping light waves;

[0047] Laser reflector 2, used to reflect the pump light wave;

[0048] The capillary 3 is used to receive the pump light wave reflected by the laser mirror 2, provide the pump light wave gain and excite the random laser;

[0049] Dye solution 5, used to act as a gain medium;

[0050] Optical filter 6, used to filter the pumping light wave;

[0051] The inner wall of the capillary 3 is coated with a layer of random dielectric film 4 mixed with nano-TiO2 particles and ultraviolet glue, and the dye solution 5 is filled inside the capillary 3 to form a random resonant cavity;

[0052] The pumping light wave generated by the pumping light source 1 is reflected by the laser reflector 2 and irradiates the random resonator to excite the random laser, which is filtered by the filter 6 after outputting the random laser.

[0053] Random laser is a r...

Embodiment 1

[0083] Such as figure 1 The shown random laser uses a pump light source 1 with a wavelength of 532 nm, a laser mirror 2 and an optical filter 6, the dye solution 5 uses an aqueous solution of rhodamine 6G, and the capillary 3 uses a 1017Q capillary with an inner diameter of 100 um and an outer diameter of The thickness is 170um, and the random dielectric film 4 is a mixture of nano TiO2 particles and ultraviolet glue.

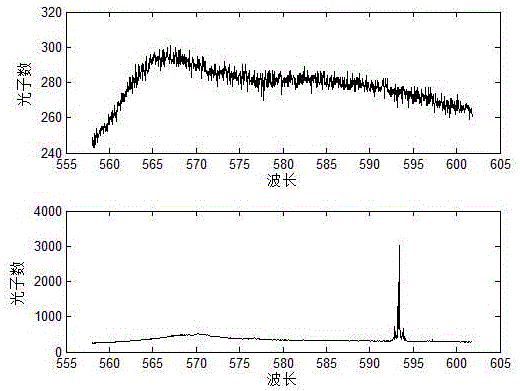

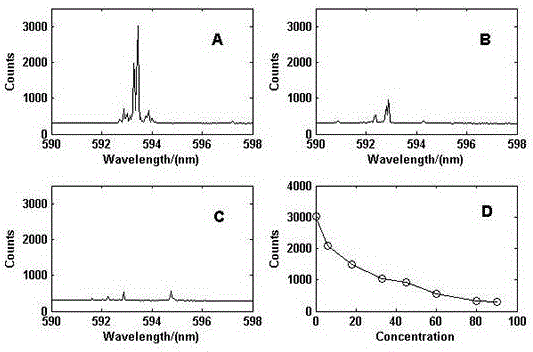

[0084] First, the effect of TiO2 particles is verified by two experiments:

[0085] The first one: only a thin layer of ultraviolet glue is coated on the inner wall of the capillary, cured by ultraviolet light irradiation, and filled with the dye solution at a constant speed through the control of a micro-injection pump. The dye solution is an aqueous solution of rhodamine 6G, wherein the filling matrix is deionized water, the gain medium is rhodamine 6G, and the concentration of the rhodamine solution is 1mol / L. exist figure 1 The spectrogram is observed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com