Iridoid compound, and preparation method, preparation and application thereof

A technology of iridoids and compounds, applied in the field of iridoids and their preparation, to achieve safe, reliable and good effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

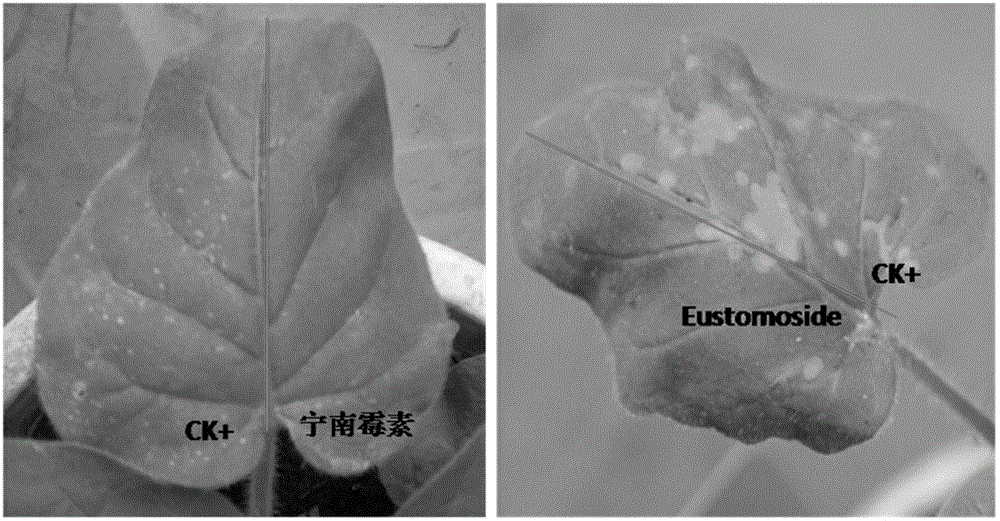

Image

Examples

preparation example Construction

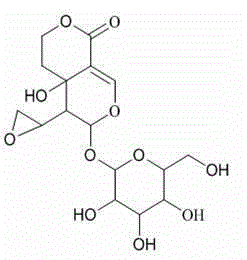

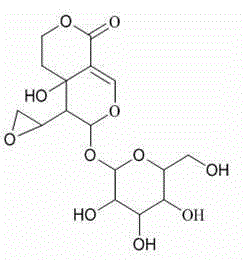

[0025] The preparation method of the iridoid compound according to the present invention is prepared by taking Southwestern Swertia as a raw material through the steps of raw material treatment, extract extraction, organic solvent extraction, elution and separation, specifically comprising:

[0026] A. Raw material processing: Take the dried Southwest Swertia japonica and crush it through a 50-100 mesh sieve for later use;

[0027] B. Extraction of extract: add methanol with a volume percentage concentration of 75-85% of the volume percentage of 2-5 times the solid-liquid volume ratio to the pre-treated Southwest Swertia sonic extraction 5-10 times, each time for 3-5h, and combine The extract is filtered, and the extract is concentrated under reduced pressure to a relative density of 1.2 to 1.3 to obtain an extract;

[0028] C. Organic solvent extraction: add water with a solid-to-liquid volume ratio of 1 to 3 times to the extract and stir for 5 to 30 minutes until it becomes ...

Embodiment 1

[0043]Take the shade-dried Southwest Swertia japonica and crush it, coarsely crush it through a 50-mesh sieve; extract 5 times with 80% methanol, 2 hours each time; combine the extracts, filter to remove residues, combine the filtrates, and then concentrate under reduced pressure to obtain leaching extracts with a relative density of 1.2. Add 1 volume of water to the extract and stir until it becomes suspended, extract twice with 98% dichloromethane solution, 15 min each time; combine the extracts, decolorize with MCI, and elute with 75% methanol , collect the eluate; then desugar on the D900 macroporous resin column, using methanol / water with a volume ratio of 0:1, 9:1, 8:2, 6:4, 3:7 and 1:0 (V / V) Solution elution, collect the eluate, monitor by TLC, combine the same parts, concentrate to get the extract, 0:1 part is separated by HPLC, eluted with 70% methanol aqueous solution, and finally Agel semi-preparative column Carry out purification, elute with 70% methanol aqueous s...

Embodiment 2

[0046] Take the shade-dried Southwest Swertia japonica and crush it, coarsely crush it through a 50-mesh sieve; extract it with 75% methanol for 10 times, each time for 3 h; combine the extracts, filter and remove the slag, combine the filtrates, and then concentrate under reduced pressure to obtain leaching powder with a relative density of 1.3. Add 3 times the volume of water to the extract and stir until it becomes a suspension, extract it with 95% dichloromethane solution for 5 times, each time for 30 min; combine the extracts, decolorize with MCI, and elute with 75% methanol , collect the eluate; then desugar on the D900 macroporous resin column, using methanol / water with a volume ratio of 0:1, 9:1, 8:2, 6:4, 3:7 and 1:0 (V / V) Solution elution, collect the eluate, monitor by TLC, combine the same parts, concentrate to get the extract, 0:1 part is separated by HPLC, eluted with 70% methanol aqueous solution, and finally Agel semi-preparative column Carry out purification,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com