Putty powder for interior walls

A technology of putty powder and interior wall, which is applied in the field of putty powder for interior walls, can solve the problems of shelling and peeling, easy mildew, endangering human physical and mental health and living environment, and achieves mildew prevention, strong sterilization and mildew resistance , the effect of inhibiting the production of mold

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

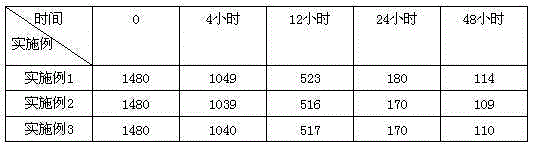

Examples

Embodiment 1

[0021] The raw material that this embodiment adopts is:

[0022] 45 parts of modified talcum powder, 30 parts of heavy calcium carbonate, 20 parts of ash calcium powder, 1.5 parts of hydroxypropyl methylcellulose, 10 parts of nano-zinc oxide, 5 parts of nano-silica, 2 parts of rubber powder, and 0.5 parts of pigment parts, wherein the rubber powder is polyvinyl alcohol rubber powder, and the pigment is green;

[0023] The preparation method is:

[0024] Add modified talcum powder, heavy calcium carbonate, gray calcium powder, nano-zinc oxide and nano-silica into the blender, stir for 20 minutes and mix well, then add carboxymethyl cellulose, rubber powder, and pigments to the blender in turn , and continue to stir for 10 minutes to make it fully mixed, that is, too.

Embodiment 2

[0026] The raw material that this embodiment adopts is:

[0027] 70 parts of modified talcum powder, 15 parts of heavy calcium carbonate, 30 parts of ash calcium powder, 2 parts of hydroxypropyl methylcellulose, 15 parts of nano-zinc oxide, 4 parts of nano-silica, 2 parts of rubber powder, and 1 part of pigment share;

[0028] Among them, the rubber powder is acrylic resin, and the raw material is red;

[0029] Its preparation method is identical with embodiment 1.

Embodiment 3

[0031] The raw material that this embodiment adopts is:

[0032] 60 parts of modified talcum powder, 20 parts of heavy calcium carbonate, 15 parts of ash calcium powder, 2.5 parts of hydroxypropyl methylcellulose, 12 parts of nano-zinc oxide, 2 parts of nano-silica, 3 parts of rubber powder, and 1 part of pigment share;

[0033] Wherein, rubber powder is the mixture of acrylic resin and polyvinyl alcohol rubber powder, and the color is yellow;

[0034] Its preparation method is identical with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com