Cu-Zn-Sn ternary alloy electroplate liquid

A cu-zn-sn, ternary alloy technology, applied in the field of electroplating solution, Cu-Zn-Sn ternary alloy electroplating solution, and alloy electroplating solution, can solve the problem of unsatisfactory appearance and color of imitation gold plating, which endangers the health of operators , narrow range of process parameters, etc., to achieve the effect of good appearance and color, wide range of process parameters, uniform plating and strong coverage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

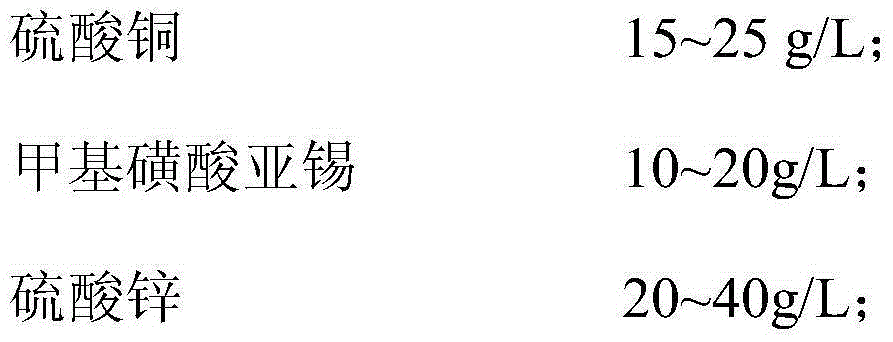

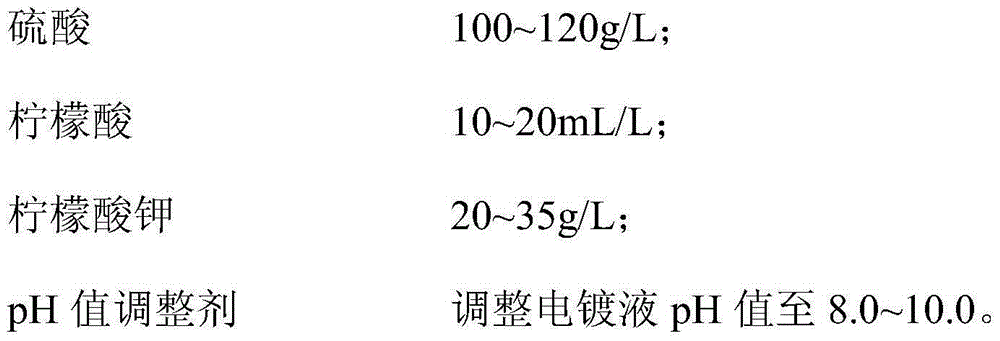

[0021] The Cu-Zn-Sn ternary alloy electroplating solution of the present embodiment comprises the component of following concentration:

[0022]

[0023] The electroplating solution of this embodiment also includes a pH adjusting agent—potassium hydroxide or sodium hydroxide, which is used to adjust the pH of the electroplating solution to 8.0.

[0024] Configure according to the above ratio, stir evenly, the anode required for Cu-Zn-Sn ternary alloy electroplating solution is stainless steel; the cathode current density of Cu-Zn-Sn ternary alloy electroplating solution is 2-4A / dm 2 ; The temperature of the Cu-Zn-Sn ternary alloy electroplating solution is room temperature.

Embodiment 2

[0026] The Cu-Zn-Sn ternary alloy electroplating solution of the present embodiment comprises the component of following concentration:

[0027]

[0028]

[0029] The electroplating solution of this embodiment also includes a pH adjusting agent—potassium hydroxide or sodium hydroxide, which is used to adjust the pH of the electroplating solution to 9.0.

[0030] Refer to Example 1 for the parameters of the Cu-Zn-Sn ternary alloy electroplating solution in this embodiment for electroplating.

Embodiment 3

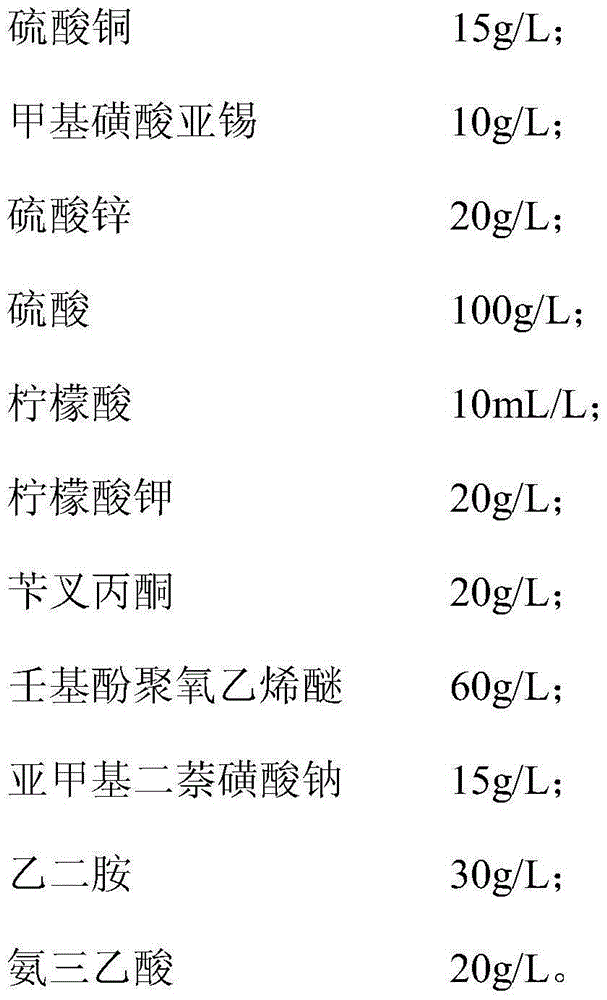

[0032] The Cu-Zn-Sn ternary alloy electroplating solution of the present embodiment comprises the component of following concentration:

[0033]

[0034]

[0035] The electroplating solution of this embodiment also includes a pH adjuster—potassium hydroxide or sodium hydroxide for adjusting the pH of the electroplating solution to 10.0.

[0036] Refer to Example 1 for the parameters of the Cu-Zn-Sn ternary alloy electroplating solution in this embodiment for electroplating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com