Method for preparing sea-buckthorn biological fodder through compound microbial flora fermentation

A compound microorganism and compound microorganism technology, which is applied in animal feed, animal feed, application, etc., can solve the problems of high cellulose content, low protein content, not suitable for livestock and poultry feed, etc., and achieve the increase and decrease of protein content. The effect of improving the disease rate and improving the comprehensive utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

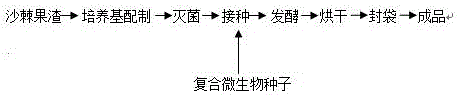

Method used

Image

Examples

Embodiment 1

[0026] The pre-cultured composite microbial seeds are pre-mixed according to the ratio of 1% Bacillus subtilis and 3% brewer's yeast. Add 2% ammonium sulfate, 0.5% potassium dihydrogen phosphate, 0.3% magnesium sulfate, 0.4% urea, and 2% glucose to the seabuckthorn pomace according to the formula, adjust the water content to about 55%, and the pH to about 5, mix uniform. The prepared seabuckthorn pomace medium is sterilized in a curved plate at a temperature of 100°C for 60 minutes, and the sterilized medium is naturally cooled to about 30°C. Insert the compound microbial seeds into the sterilized seabuckthorn pomace medium, the inoculum amount is 4%, and then ferment at 30±5°C for 60 hours; the fermented seabuckthorn biological feed is dried at 55~60°C, crushed to 80 The finished product can be obtained by quantitative sub-packaging. The protein content of the product is 40.42%.

Embodiment 2

[0028] The pre-cultured composite microbial seeds are pre-mixed according to the ratio of 0.8% Bacillus subtilis and 4% brewer's yeast. Add 1.5% ammonium sulfate, 0.8% potassium dihydrogen phosphate, 0.5% magnesium sulfate, 0.6% urea, and 2% glucose to the seabuckthorn pomace according to the formula, adjust the water content to about 58%, and the pH to about 5.2 ,well mixed. The prepared seabuckthorn pomace medium is sterilized in a curved plate at a temperature of 98°C for 90 minutes, and the sterilized medium is naturally cooled to about 30°C. Insert the compound microbial seeds into the sterilized seabuckthorn pomace medium, the inoculum amount is 5%, and then ferment at 30±5°C for 48 hours; the fermented seabuckthorn biological feed is dried at 55~60°C, crushed to 60 The finished product can be obtained by quantitative sub-packaging. The protein content of the product is 40.16%.

Embodiment 3

[0030] The pre-cultured composite microbial seeds are pre-mixed according to the ratio of 1% Bacillus subtilis and 4% brewer's yeast. Add 2% ammonium sulfate, 0.4% potassium dihydrogen phosphate, 0.2% magnesium sulfate, 0.5% urea, and 1.5% glucose to the seabuckthorn pomace according to the formula, adjust the water content to about 60%, and the pH to about 6, mix uniform. The prepared seabuckthorn pomace medium is sterilized in a curved plate at a temperature of 100°C for 60 minutes, and the sterilized medium is naturally cooled to about 30°C. Insert the compound microbial seeds into the sterilized seabuckthorn pomace medium, the inoculum amount is 5%, and then ferment at 30±5°C for 48 hours; the fermented seabuckthorn biological feed is dried at 55~60°C, crushed to 100 The finished product can be obtained by quantitative sub-packaging. The protein content of the product is 41.08%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com