A kind of garlic straw active dietary fiber and its preparation method

A garlic straw and dietary fiber technology is applied in the field of dietary fiber preparation, which can solve the problems of environmental pollution, waste of resources and the like, and achieve the effects of less environmental pollution, low production cost and high soluble dietary fiber content.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

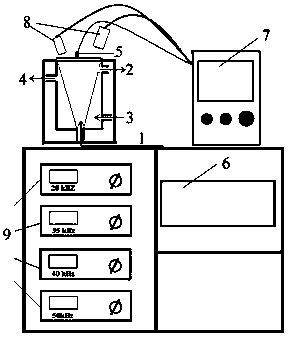

Method used

Image

Examples

Embodiment 1

[0019] (1) Raw material pretreatment: garlic straw raw material was dried at 60°C, mechanically crushed and passed through a 60-mesh sieve, and 25 g of straw powder was weighed, and 1000 mL of distilled water was added according to the ratio of material to liquid: 1:40;

[0020] (2) Ultrasonic treatment: the countercurrent feed rate is 60 mL / min, the constant cooling water temperature is 25°C, the total time of circulating ultrasonic is 30 min, the dual-frequency frequency is 28 kHz / 35 kHz for the first 10 min, and the dual-frequency The frequency is 35 kHz / 50 kHz, the ultrasonic power of each probe is 400 W, the ultrasonic working time is 2 s, and the intermittent time is 2 s;

[0021] (3) Enzymatic hydrolysis: adjust the pH of the ultrasonic treatment solution to 6.0, add 5% (E / S) cellulase, enzymatically hydrolyze at 50°C for 3 h, and inactivate the enzyme at 95°C for 10 min after the enzymolysis;

[0022] (4) Alcohol precipitation: add 4 times the volume of 95% ethanol to ...

Embodiment 2

[0026] (1) Raw material pretreatment: garlic straw raw material was dried at 50°C, mechanically crushed and passed through a 60-mesh sieve, and 33.3 g of straw powder was weighed, and 1000 mL of distilled water was added according to the ratio of solid to liquid: 1:30;

[0027] (2) Ultrasonic treatment: The countercurrent feed rate is 80 mL / min, the constant cooling water temperature is 35 °C, the total time of circulating ultrasonic is 30 min, the dual-frequency frequency is always 40 kHz / 50 kHz, and the ultrasonic power of each probe is 500 W, ultrasonic working time 3 s, intermittent time 2 s;

[0028] (3) Enzymolysis: adjust the pH value of the ultrasonic treatment solution to 6.0, add 4% (E / S) compound enzyme of cellulase and protease (10:1), enzymolysis at 50°C for 4 h, after the end of enzymolysis Inactivate the enzyme at 95°C for 10 min;

[0029] (4) Alcohol precipitation: centrifuge the enzymatic solution at 5000 rpm for 15 minutes, add 4 times the volume of 95% etha...

Embodiment 3

[0033] (1) Raw material pretreatment: the garlic straw raw material was dried at 60°C, mechanically crushed and passed through an 80-mesh sieve, and 20 g of straw powder was weighed, and 1000 mL of distilled water was added according to the ratio of material to liquid: 1:50;

[0034] (2) Ultrasonic treatment: countercurrent feed rate was 50 mL / min, constant cooling water temperature was 25°C, total cycle ultrasonic time was 50 min, the dual-frequency frequency was 40 kHz / 50 kHz for the first 25 min, and the dual-frequency frequency for the last 25 min was The frequency is 35 kHz / 50 kHz, the ultrasonic power of each probe is 400 W, the ultrasonic working time is 2 s, and the intermittent time is 2 s;

[0035] (3) Enzymolysis: adjust the pH of the ultrasonic treatment solution to 6.0, add 3% (E / S) cellulase, and enzymatically hydrolyze at 50°C for 5 hours, and inactivate the enzyme at 95°C for 10 minutes after the enzymolysis;

[0036] (4) Alcohol precipitation: After concentrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com