Compound zinc-iron calcium granule and preparation method thereof

A zinc-iron-calcium compound technology, which is applied in pharmaceutical formulations, medical preparations containing active ingredients, powder delivery, etc., can solve the problems of large differences in vitamin B2 content and unstable effects, and achieve the effect of avoiding discoloration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

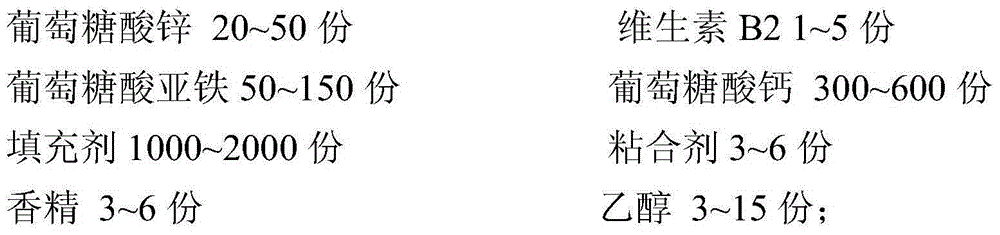

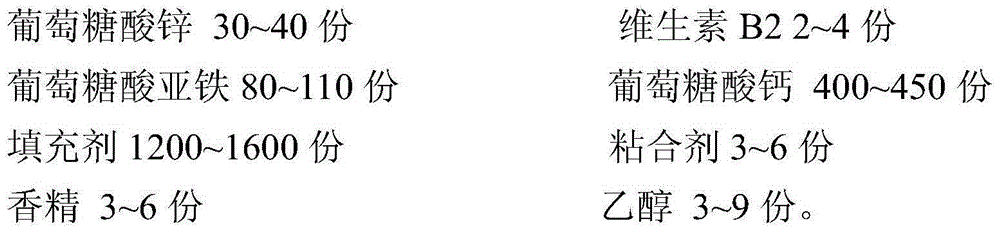

Method used

Image

Examples

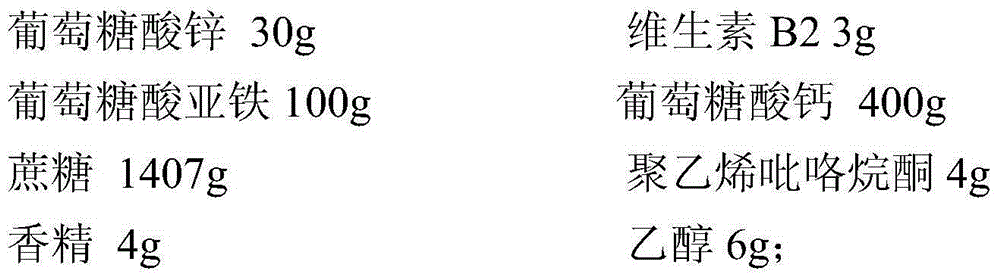

Embodiment 1

[0029]

[0030] (1) Adhesive: Dissolve vitamin B2 in ethanol to prepare vitamin B2 ethanol solution, and prepare 2% polyvinylpyrrolidone aqueous solution, mix vitamin B2 ethanol solution and 2% polyvinylpyrrolidone aqueous solution evenly, and put it in a spray tank for later use.

[0031] (2) Mixing: Weigh the raw and auxiliary materials of the prescription amount respectively, first pour zinc gluconate and ferrous gluconate into the mixer and mix, and finally add calcium gluconate, sucrose and essence and mix evenly, and set aside.

[0032] (3) Granulation: Open the pot cover, put the raw materials in step (2) into the feeder of the one-step granulator, turn on the fan and heat it, so that the material is evenly heated to 50°C in a fluidized state, turn on the spray button, and spray Adhesive, the liquid inlet speed is 27ml / min, the atomization pressure is 0.12MPa, the air inlet temperature is then controlled at 80°C, and the material temperature is then controlled at 60°C...

Embodiment 2

[0034]

[0035] (1) Adhesive: Dissolve vitamin B2 in ethanol to prepare vitamin B2 ethanol solution, and prepare 2% polyvinylpyrrolidone aqueous solution, mix vitamin B2 ethanol solution and 2% polyvinylpyrrolidone aqueous solution evenly, and put it in a spray tank for later use.

[0036] (2) Mixing: Weigh the raw and auxiliary materials of the prescription amount respectively, first pour zinc gluconate and ferrous gluconate into the mixer and mix, and finally add calcium gluconate, sucrose and essence and mix evenly, and set aside.

[0037] (3) Granulation: Open the pot cover, put the raw materials in step (2) into the feeder of the one-step granulator, turn on the fan and heat it, so that the material is evenly heated to 50°C in a fluidized state, turn on the spray button, and spray Adhesive, the liquid inlet speed is 30ml min, the atomization pressure is 0.12MPa, the air inlet temperature is then controlled at 85°C, and the material temperature is then controlled at 55°C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com