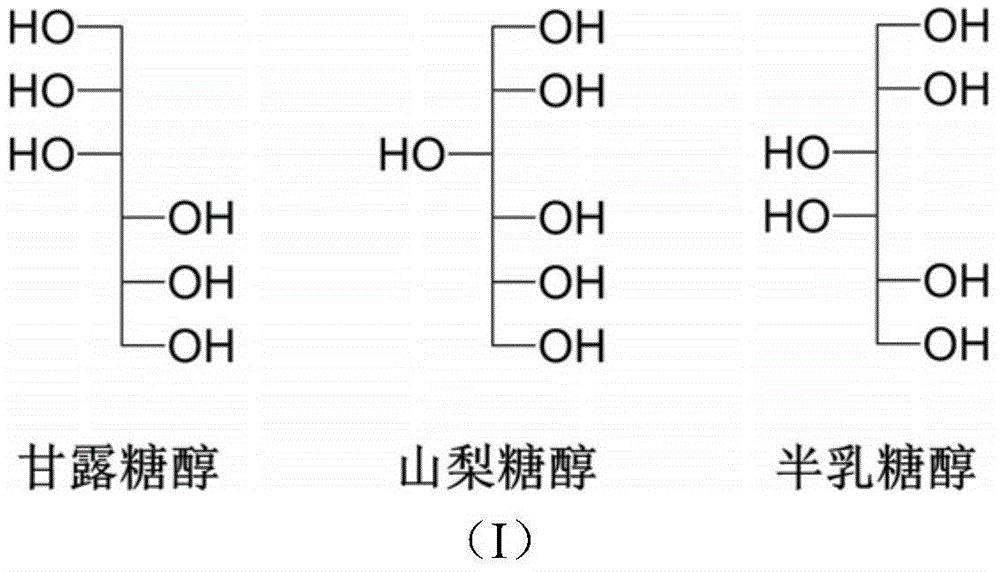

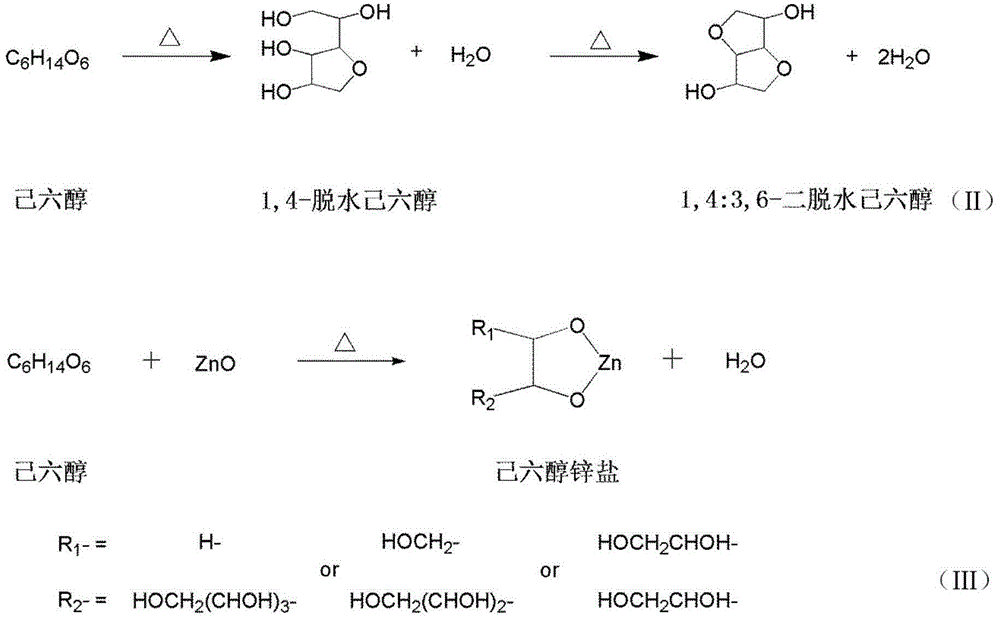

Metal oxide-hexanehexol compound heat stabilizer, preparation method and application in PVC

A technology of heat stabilizer and hexanol, applied in the field of plastic processing aids, can solve the problems of complex heat stabilizer preparation, complicated preparation method of stabilizer, etc., and achieve simple components, good initial colorability, and good market prospects. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The preparation of embodiment 1 metal oxide-hexanehexanol composite thermal stabilizer

[0024] Mannitol (5.47g, 0.03mol) and zinc oxide (2.44g, 0.03mol) were added into a 250mL three-necked flask at a molar ratio of 1:1, mechanically stirred at a stirring rate of 50rpm, and in an air atmosphere, The reaction was carried out in an oil bath at 200° C. for 2 hours. After cooling, the product is ground into fine powder and sieved with a 200-mesh steel sieve to obtain the zinc oxide-mannitol complex.

Embodiment 2~5

[0026] The method of Example 1 was used to prepare the metal oxide-hexanehexanol composite, except that the type of metal oxide was changed, as shown in Table 1.

[0027] Table 1

[0028] Example serial number

Embodiment 6、7

[0030]The method in Example 1 was used to prepare the metal oxide-hexyl alcohol composite, the metal oxide was zinc oxide, and the type of hexyl alcohol was changed, see Table 2.

[0031] Table 2

[0032] Example serial number

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com